Acoustic Design Project

Gear / Treatment

Wars

As a mix engineer, we need tools. Some of us need more tools than others. We need electronic tools but we also need room treatment tools. Tools or gear take up space. Treatment takes up space, especially low-frequency tools. In today’s small rooms space is at a premium. We have the need for electronic tools to do our craft so those tools get priority within the available space. Where can we put the other tools? The absorption technology for low-frequency management. Where can we get enough surface area to manage the low- frequency pressure issues within our rooms? How do we manage the reflections from our wall surfaces so we hear more direct or straight line energy from our monitors? Should we use diffusion? If so, where do we place it? Let’s look at some treatment options and where to place them. Let’s start with the low end.

Building a room within a room

Low – frequency energy oscillates through our rooms like ocean waves. It’s like the mail, it keeps coming. It never stops. To manage this energy, we need sponges to soak up the excess “water” from each wave cycle. We need to do this to avoid the mixing challenge of room modes. Room modes can exaggerate or attenuate energy to a level where you will hear more of a certain octave band or nothing at all. Every room surface and the dimensions from wall to wall will determine what frequencies at what location and what amplitude those issues are. You could have 30 Hz. issue on your shorter wall and a 40 Hz. issue on the longer walls. You could have 60 Hz. issue with the floor to ceiling dimension. The dimensions of your room determine what wavelength of energy will fit and what will not. To manage the lower frequency issues within our mix rooms we need to have so much square footage of coverage using the correct rate and level of absorption on each wall surface area. If that wall produces 40 Hz. issue, we must use technology that absorbs at 40 Hz. and we must use enough of it to reduce the peak energy levels down to a place where we can EQ the rest.

Low -frequency management technology ranges from 16″ deep to get to 30 Hz. to 12″ deep to achieve a 40 Hz. level of absorption. Since our walls are the problem, we must ideally build a new treatment room inside our existing room. The treatment room will be a series of panels that are positioned along each wall surface area. In this room, it is going to be a challenge. We will need 12″ of space to treat down to 40 Hz. and we will need 16″ of space to treat down to 30 Hz. Where are we going to find that space availability without disrupting work flow? For the solution, we are going to turn to our Activated Carbon Diaphragmatic Absorber (ACDA-10/12) modules and our Carbon Panel modules. Our module series can be built and sized to fit the space requirements we have to work within.. We can change the height and the width to work within the existing space requirements but if we need to go down to 30 Hz., the modules must be 16″ deep. If we need to go down to 40 Hz. they must be 12″ deep. This can not change. In this room, we have 32 Hz. issue along the front and rear walls. We have 42 Hz. issue along the long walls which are the sidewalls.

Stacking acoustic treatment for more absorption

Back to the front and rear walls with a 63 Hz. issue and our standard 70 cycle issue with the 8 ‘ floor to ceiling dimension. Looking at the sidewalls again, we have 83 Hz. dip and then back to the front and rear walls for a 94 Hz. problem that is + 5 dB over baseline. We will need at a minimum 75 sq. feet of surface area coverage along the front wall and the same 75 sq. ft. along each sidewall. Since low-frequency absorption technology is pressure based, we must provide enough surface area coverage on each offending surface area to avoid creating phase issues. If we use 50 sq. ft. of coverage on one wall surface area we must use that same amount on the opposite surface areas. Remember that the definition of an axial mode is unwanted pressure between two parallel walls not two parallel corners. It is the walls of our rooms that are the problem. If you want to get rid of the modal issues within your room, get rid of the walls. The best room size to avoid all axial, tangential, and oblique modal issues is no room at all.

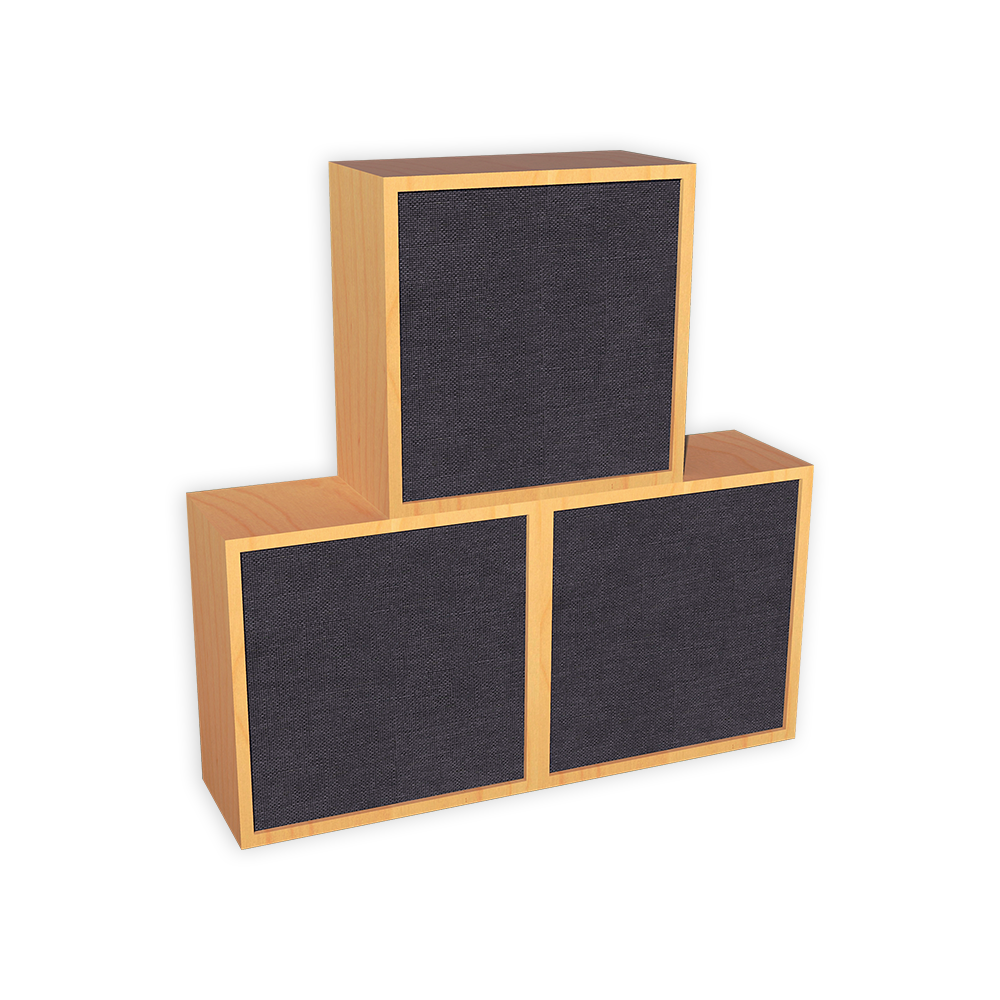

We will move some gear around away from the walls and insert a series of modules against the front and rear walls for our phase 1 treatment. We will use modules that are 12″ x 12″ x 12″ under the console. We will use larger modules that are 18″ x 18″ for the sidewalls and we will stack them on top of each other creating a “wall” . Remember with low-frequency pressure management, it is all about the amount of square feet of coverage we can fit into the existing space to treat the issues. It doesn’t matter what the size of each module is. What matters is that we can place enough of them in the given space to achieve our surface area coverage requirements which are dictated by the frequency and amplitude issues at each wall location. The ACDA and Carbon Panel modules can be mixed together to treat any issue on any wall surface area and where treatment availability is an issue, we can use the modules in a stacking configuration to achieve our lower frequency absorption requirements.

Products in this project

ACDA-10 M | Modular Bass Absorber

The ACDA -10 modules are our highest performing product. They follow the absorption coefficients of the ACDA-10 with a stronger emphasis on the 60 – 80 Hz. range. The full range absorption for each module is 30 Hz. – 6,500 Hz.

This increased performance comes in a module that is 24″ x 24″ x 12″ and weighs 70 lbs. Modules are stackable and the number and surface area coverage can be fined tuned in your room size/volume/usage.

ACDA-12 M | Modular Bass Absorber

Our new ACDA-12 modules provide the same performance as our ACDA-12 units. Units are 48″w x 30″h x 12″ d and weigh 150 lbs. The ACDA-12 modules are stackable and provide the performance of our most powerful carbon-absorbing unit. We achieve 35% at 30 Hz. 63% at 40Hz. and 100 % at 50Hz.

There is no greater performing low frequency absorbing unit in the marketplace than our ACDA-12 unit.

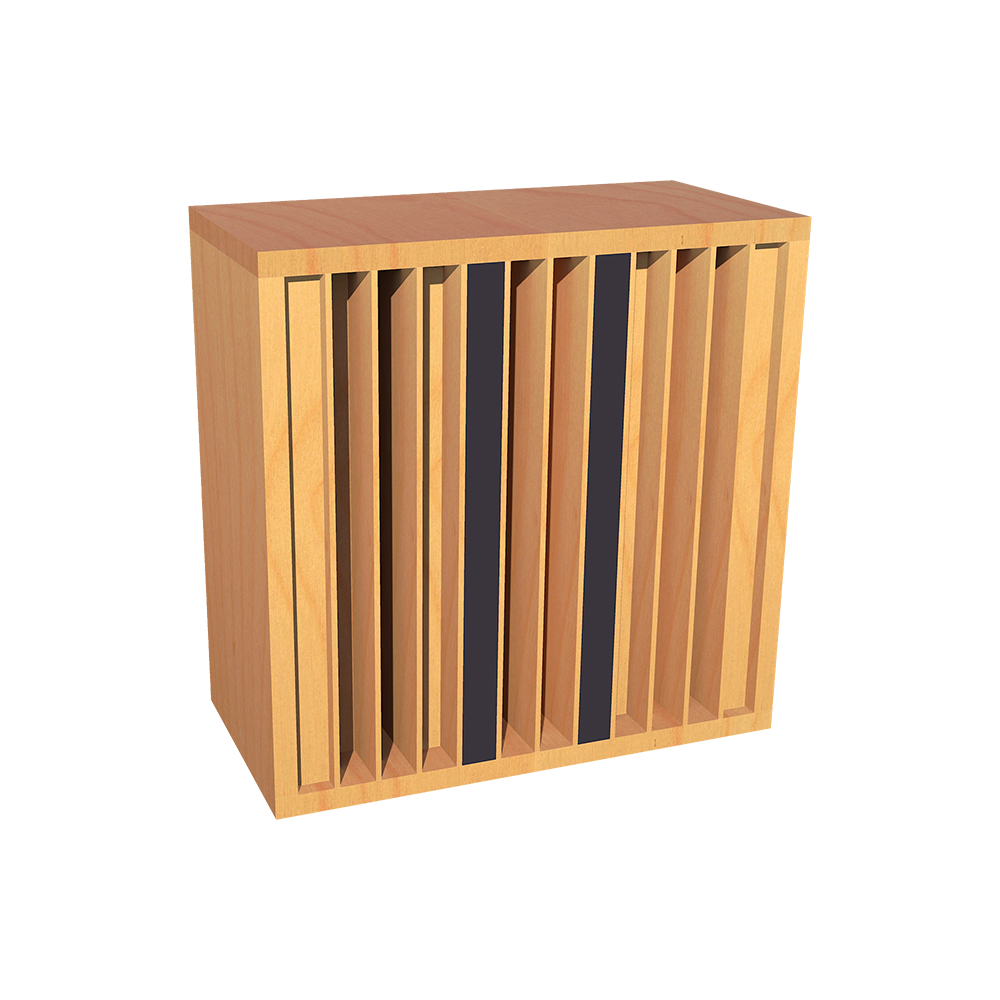

QDA-13 M | Modular Diffuser / Absorber

It is important to have both frequency-specific and broadband low-frequency absorption on all wall surfaces. Our QDAM-13 has our carbon technology installed inside the diffuser itself.

You achieve the same performance as our ACDA-10M and the power of prime number 13 diffusion all in our 24″ x 24′ x 12″ d module that you can stack and create both one dimension and two dimension diffusion.

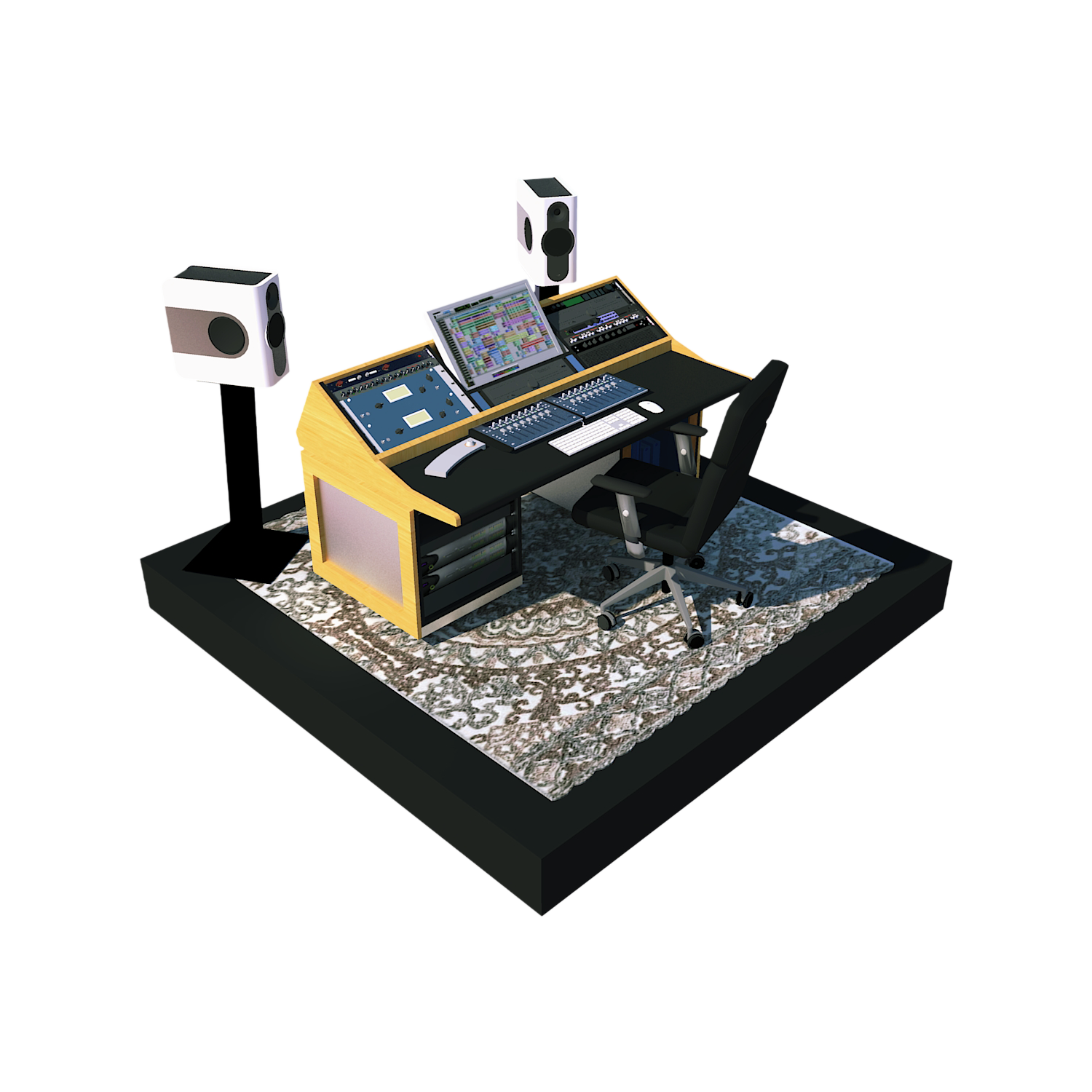

Digital Audio Workstation Platform

The floor to ceiling dimensions in our rooms is the smallest of the three total dimensions. Since it is the smallest, it will produce unwanted low -frequency pressure issues around 50 – 70 Hz. The issue then becomes how do we treat this 50 – 70 Hz. + 8 – + 10 dB issue between our 8′ ceiling height and the floor where we have our DAW. Our DAW is sitting between the floor and the ceiling and it is sitting in a “pool” of low frequency modal soup that will have a negative impact on our mixes.

Do you want to solve your room acoustic problems?

There’s no one size fits all when it comes to room acoustics.

Get your FREE personal room acoustics analysis by chief acoustics engineer Dennis Foley.