Table of Contents

Versatile Home Theater Wall Panels

Home theater wall panels take many forms and shapes. We have home theater wall panels that are used for sound absorption. We have home theater wall panels that are used for diffusion. We also have technologies that are used for home theater wall panels that combine both absorption and diffusion technologies. The first objective in any acoustical design project is to choose the correct room dimensions to match the intended usage of the room.

We want to choose room dimensions that can handle a lot of lower frequency energy since home theater wall panels must deal with large amounts of low, middle, and high frequency energies. Choosing the correct room volume that can manage lower frequency energy will save space and material costs as we move through the design. We must first focus on the low frequency issues in any home theater wall panel design and implementation.

Starting with Low Frequency Absorption in Home Theater Design

Home theater wall panels must first start with absorbing the lower frequency energy within our home theaters. The “bass” energy is any energy below 80 hz. This is a frequency that is in all car crashes and explosions. It is also the lower range of male voice. Managing lower frequency pressure waves requires a special absorption technology. At Acoustic Fields, we design low frequency absorption technologies. We use diaphragmatic absorption which per square foot is the most powerful of all the technologies. It is also the most expensive to manufacture and ship.

Our ACDA series has two front walls that are out of phase with each other. Their function is to slow the pressure wave of lower frequencies down. After the pressure wave strikes our dual front wall and is slowed down, it enters the inside of the cabinet where our proprietary activated carbon technology is suspended inside a perforated absorber. We are the first company to place a perforated absorber inside a diaphragmatic.

Advanced Diaphragmatic Absorption

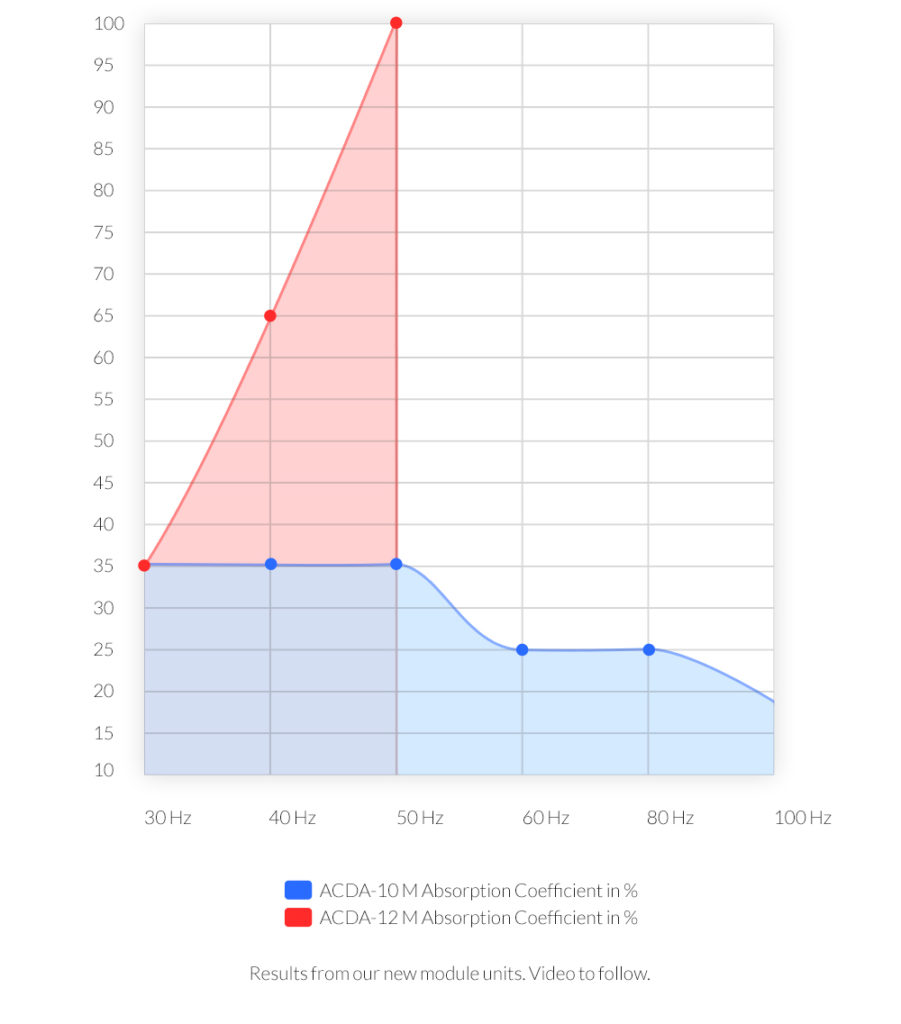

The depth of our ACDA series along with our Carbon Panel controls the lowest resonant frequency the unit will begin working at. The carbon on the inside manages the rate of absorption or how much energy the unit absorbs at each octave band. On the face of each unit directly behind the fabric is our proprietary foam technology. Our foam technology extends the frequency range for the ACDA series 30 hz. – 6,300 hz.

Our Carbon Panel starts at 40 hz and goes through 6,300 hz. In order to reach 30 hz., our ACDA series is 16″ deep. Our Carbon panel which starts at 40 hz. is 12″ deep. Remember that the cabinet depth dictates the lowest resonant frequency the overall unit will perform at. The Carbon Perforated Absorber inside the dual wall cabinet manages the rates of absorption.

Balancing Low, Mid, and High Frequencies

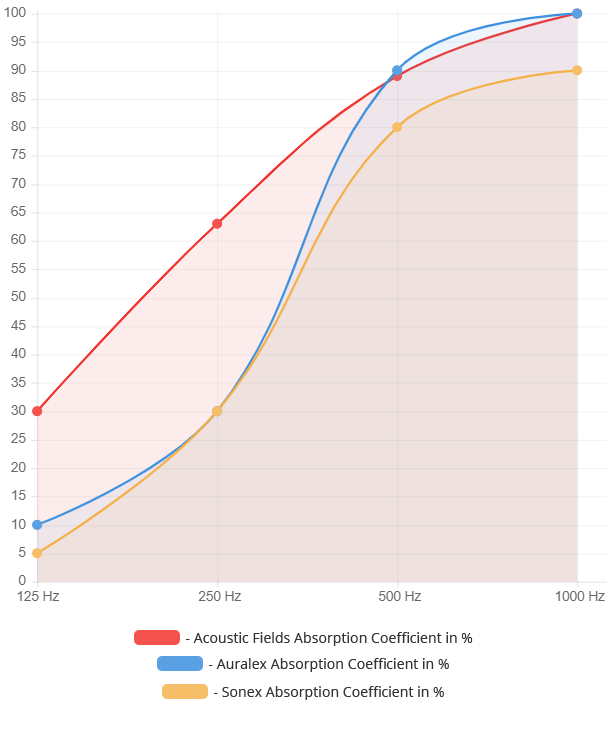

Home theater wall panels must be able to deal with lower frequency pressure along with middle and high frequency reflections. We have pressure waves within our rooms that are lower frequency energy. We have middle and high frequency reflected energy from the walls, floors, and ceilings within our rooms. To manage the middle and high frequency reflections, we must place enough home theater wall panels on each room surface area.

We must also place the proper rate and level of absorption to deal with reverberation which the reflections produce. Reverberation is defined as to how long a sound stays around with a room after it has been sung,spoken, or played. Reverberation is a form of room acoustical distortion and has a negative impact on speech intelligibility. SI is defined as to how many words can be heard clearly within a ten word sentence. The goal is 8 out of 10. Our brains will fill in for the missing words.

Addressing Room Acoustics: Pressure Waves vs. Reflected Ray Energy

In any small room where music and voice is the usage, we will have both pressure and reflection issues. Pressure waves are dramatically different from reflected ray energy. Pressure waves require a different treatment technology than reflections. You must always match the treatment technology to the acoustical issues.

A pressure wave oscillates through the room and first has to be slowed down so more absorption can occur. A middle and high frequency reflection technology works on air flow across its surface areas. A common form of reflection management technology is open celled foam. There are two main types of foam. Open celled is used for sound absorption. Closed cell is used for support such as in seat cushions and couches. Closed cell foam is as the name implies. Its cells are closed for more structural rigidity.