Ceiling Foam Panels

Ceiling foam panels come in many types and sizes. You must choose the type of panel you wish to use, the rate and level of its ability to absorb, and the position of the ceiling foam panels to match room usage. Ceiling foam panels come in many thicknesses. The thickness of the ceiling foam panels determines how low the foam will absorb down to. You must know what frequency and amplitude of the sound pressure you are dealing with in order to select the proper panel to match the room sonic requirements. Many people choose too thin of a panel to deal with the amount of energy they are trying to absorb. You must first measure the problem you are having within the room and then assign the correct rate and level of absorption to deal with that room surface frequency and amplitude issue.

Open Celled Foam

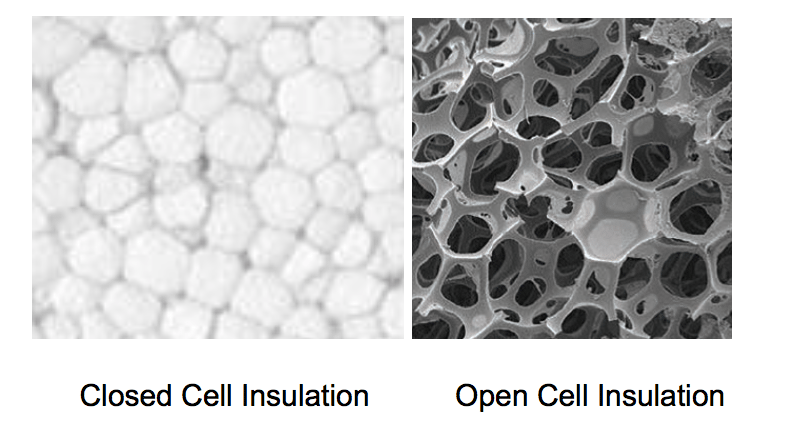

Ceiling foam panels are made of open-celled foam. Open-celled foam is different than closed celled foam. Open celled foam is designed to support the absorption of excess sound energy for middle and high-frequencies within your room. Closed-cell foam is designed to support your rear end. Closed celled foams are used in seat cushions and couch pillows. They are not designed to support sound absorption processes. Open-celled foams are designed with one sole purpose. They try and capture as much energy as possible within every square foot of sound. We call these foams “noise” foams. These are the foams that will make your room sound too dead. We have all heard rooms covered in this foam type. The voice and music sound lifeless and dead. This is the result of over absorption using “noise” foams. Music and voice are different than noise. You must use sound absorption technology that is a professional studio designed technology with the proper rates and levels to absorb music and voice.

Design

Open – Celled foam is called open-celled for a reason. The cell structure is open to allow for airflow to enter the cells. When air enters the cell friction is created between the air movement and the cell structure. When friction is created, we generate heat. Heat is an energy change. This energy transformation produces absorption. By controlling the cell width and depth, you can maximize the performance of the absorption process. If you also control the cell structure’s uniformity, you can create linearity in the rate and level of performance. This is what we have achieved with our Studio Pro Foam technology.

Studio Pro Foam

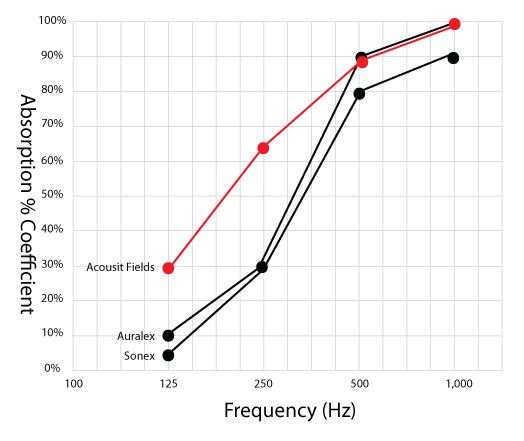

We have spent 8 years developing our Studio Pro Foam technology. it was specifically designed for music and voice. It was not designed for noise. This is why it took so long to create. We had an absorption curve goal that we wanted to achieve. We came across this absorption curve with its rate and level of absorption as a result of testing corporate boardrooms where voice definition is critical and understanding voice in small rooms is a requirement. We discovered after over 100 rooms tested that the area from 125 Hz. – 250 Hz. was underrepresented in all forms in the marketplace. We also realized that this 125 – 250 Hz. region is critical, not only for vocals but for music. Just ask any mix engineer who has worked with voice and music. They will tell you that getting this lower mid-range correct is essential in any mix. If you don’t get the mids correct in this frequency range, you struggle with getting it right on all frequencies above 250 Hz. Here are our foam absorption curves. Notice the smooth transition from 125 – 250 Hz.

Floor / Ceiling

The floor to ceiling dimension in most small rooms is the smallest of the three dimensions. The width and length of the room are usually larger in distance. The floor to ceiling dimensions creates two types of energy issues. First, since most ceiling dimensions in North America are 8′, we have numerous low-frequency pressure issues that are created by this 8′ distance. Second, we have reflections from middle and high-frequency energy issues that are produced by our speakers or human voice as in office settings. If you are going to treat the lower frequency issues within the room, the technology will need to be 6″ – 10″ deep and weigh much more than ceiling foam panels. If you are not treating low-frequency issues in the ceiling, then you can treat middle and high-frequency reflections with ceiling foam panels. You must first identify the frequency and amplitude (strength) of your problem before you assign any treatment type or amount.

Drop Ceilings

One popular yet not high in absorption is the Armstrong ceiling panels that are used within drop ceilings. These are 1/2″ thick compressed fibers that are formed into 24″ x 24″ and 24″ x 48″ pieces that insert between the grids in a drop ceiling. Any material that is 1/2″ thick will not have the ability to absorb much energy. With middle and high-frequency absorption, the thickness of the foam will determine how effective it will be in your particular situation. We have taken the Armstrong ceiling tile and attached our 2″ foam technology to the tiles. We have added a wood frame around the foam. With this system, you can keep your drop ceiling grid and increase the rate and level of absorption drastically.

Ceiling Foam Panels: https://acousticfields.com/product/suspended-ceiling-foam-tile/

Application

When using any foam technology, you must always calculate the rate and level of absorption of the technology you are considering along with the proper amount of surface area coverage. This is where most fail at the process and waste money on a solution that does not have the desired impact. You must measure the noise issue, assign the proper technology, and install enough of it to have the desired impact whether it is increasing speech intelligibility or managing noise. Most applications require a complete surface area coverage to minimize the impact of noise issues. Some installations only place the materials over the noise source without realizing that the noise issue requires large surface area coverages with the proper rates and levels of absorption.

About Us At Acoustic Fields: https://acousticfields.com/about/

The discussion on ductwork noise transmission from Acoustic Fields highlights crucial aspects of HVAC system acoustics. The movement of air…

Great build plans. thank you Denis

You must use absorption. Never place a chair against a wall.

A friend and I built several diffusors using these plans and they turned out absolutely beautiful. Very good instructions and…