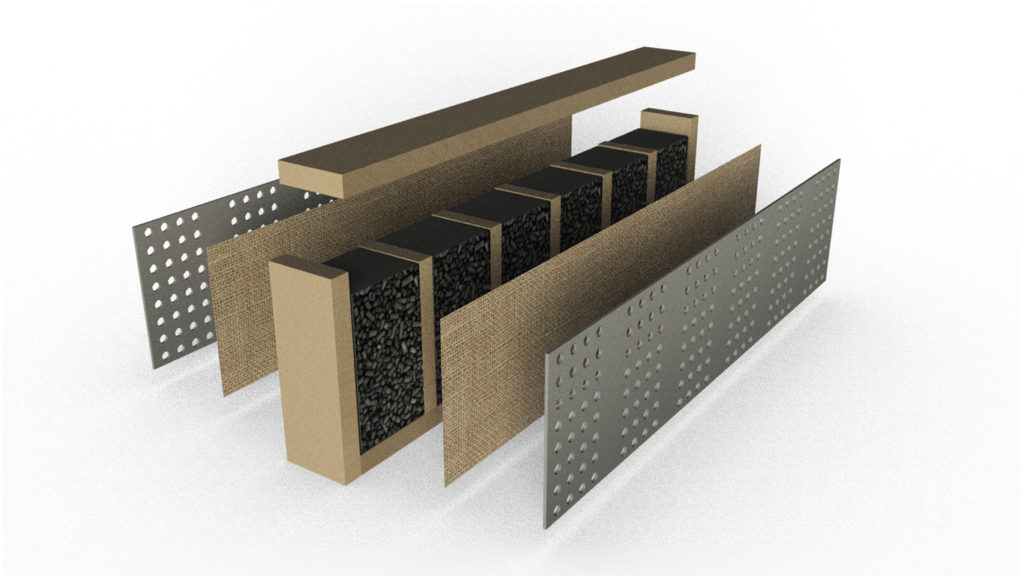

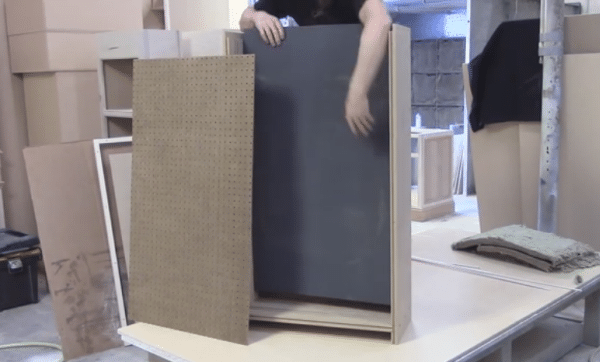

When you see the search term bass trap diy your mind can conjure up many images. The bass trap diy could be a box filled with foam or a box filled with building insulation. It could be made of foam which is not a low frequency absorption technology. The person doing this bass trap diy search is looking for two things. They are hoping for a sonic solution to the unwanted room modal issues they hear within their room and they are trying to save money by contributing their labor to the project. We have a program where we sell you the carbon to go inside your cabinet, you build the carbon support structure per our drawings, and then insert the carbon filter inside the cabinet that you build per our drawings out of 1″ MDF. We sell you the carbon for the cabinet inside and the foam to go on the face of each BDA/DIY unit. In our production units, the foam is positioned behind the black face fabric. At Acoustic Fields www.acousticfields.com we offer a DIY series of products and production units which you purchase from us.

A bass trap diy should be powerful and work well. If you are going to put that much work effort into building many units, the average build is 8 units, you must have a finished product that is guaranteed to work. If it doesn’t work, we will pay for your materials and labor. The BDA units are heavy weighing in at 230 lbs. when all finished and on casters, You must place the units on casters for two reasons. First, they are heavy and need wheels and secondly the casters allow for tuning the room by moving the units closer and farther away from each wall surface area. The BDA/DIY units when finished measure 30″ w x 60″ h x 16″ deep. They will start absorbing at 30 Hz. and going up through 6,300 Hz. with our foam face technology. Make sure you have 3 years woodworking experience, a table saw, and strong working tables.. You will be using 3/8″ MDF, 1/2″ MDF, and 1″ MDF in the build. Before you decide how many to build, you should let us look at your room and help you locate your low-frequency issues first and then we can prescribe the treatment amount and position and you can build them. The analysis gives you a road map to follow showing how many square feet of coverage you need on each room surface area.

https://www.acousticfields.com/free-room-analysis/

When we are installing any type of acoustical treatment, we need to follow the acronym TAP. TAP stands for type, amount, position. We have analyzed our frequency and amplitude issues and now we must decide on the type of treatment that will treat our identified issues. https://en.wikipedia.org/wiki/Room_modes This is where most people fall down. They can identify the problem but they end up using the wrong treatment type to resolve their issues. The next place people fail at is that they do not use enough of the treatment type to resolve their issues. In small rooms, most walls take 50 – 70% surface area coverage in order to reach what we call in physics critical mass. You must have the proper square footage of coverage to treat the issues you have. Placing a few panels here and there will not be enough surface area coverage. Finally the positioning of the treatment is critical. Every wall surface exhibits certain frequency and amplitude problems. You must identify those issues and treat them at their respective locations. https://www.merriam-webster.com/dictionary/reverberation.

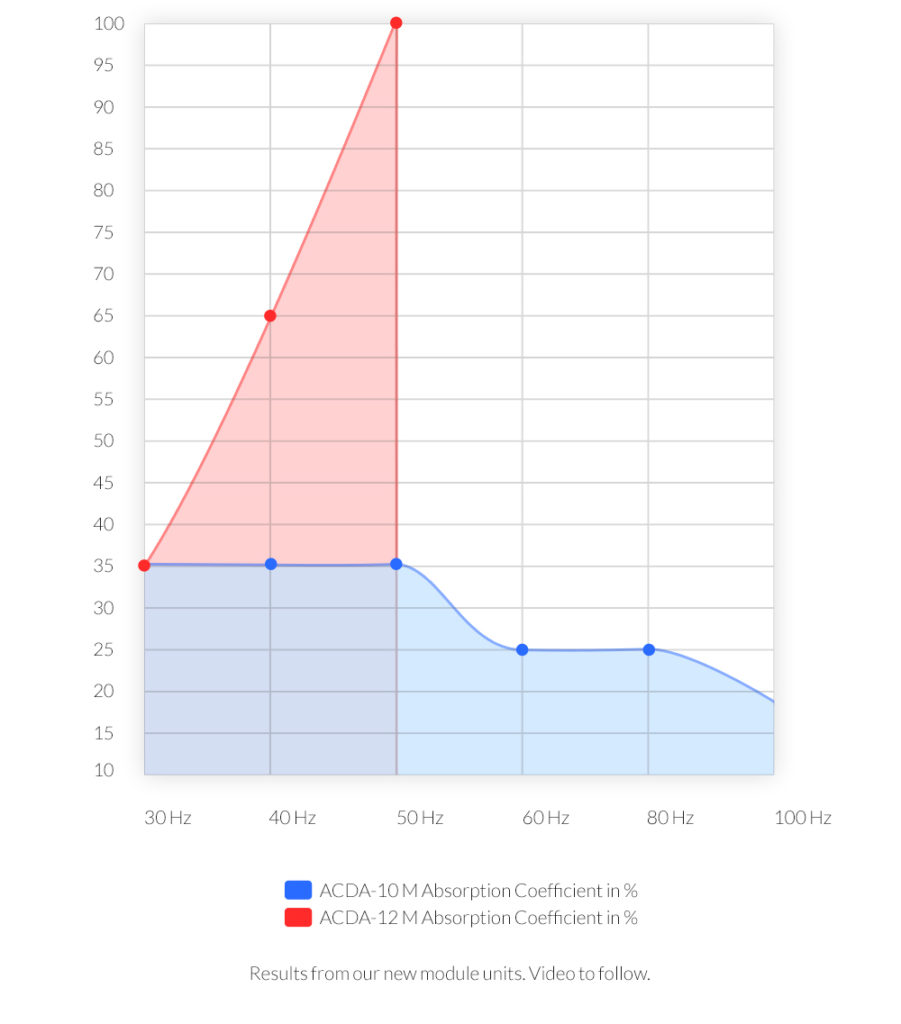

When you are building your bass trap diy, you must build enough units to treat the issues you have. Over the last 12 years, we have been keeping data on how many units people build or buy for their rooms that treat low-frequency energy. Our data shows that most clients build or purchase a minimum of 8 of our Carbon Panels or bass trap diy. With 8 units, you will receive around 100 square feet of surface area coverage with each unit producing 12 sq.ft. of surface area. Since low-frequency absorption technology is deep compared to middle and high frequency technology, we want to minimize the footprint and maximize the performance in the treatment space we are provided with in our small rooms. This is why we choose broadband absorption that starts at 30 Hz. for the ACDA series and goes through 6,300 Hz. as our frequency response range. The carbon technology goes inside the unit and handles the excess energy from 30 – 300 hz. Our proprietary foam technology takes over after 300 Hz. and completes the linear absorption curve all the way through 6,300 Hz. https://www.acousticfields.com/product/acda-10-activated-carbon-diaphragmatic-absorber/

If you do not have room for the BDA unit which is large, you can break the unit up into modules and stack the modules throughout your room in the problematic areas. Our modules are 24″ x 24″ x 12″ and can be stacked on top of each other to produce the proper surface area coverage that will be required to treat low-frequency issues. https://www.acousticfields.com/product/acda-10-m-modular-bass-absorber/ Most two channel rooms require treatment on the front wall along with the sidewalls. The rear wall should also be treated but if budget and space are concerns, we need to address those surface areas first and foremost. The ceiling falls into this paradigm also. I always tell clients to treat the front and side walls first and then if you start to hear the ceiling, we can treat it. Treating the ceiling is a middle and high frequency treatment issue and can be easily treated with our foam technology. Our Foam Ladder product is our 2″ proprietary foam technology with a wood frame around it to allow you to hang it from any ceiling system. https://www.acousticfields.com/product/foam-ladder/. Our foam technology across the wall surface areas will manage reverberation or reflections from each wall surface area.

The discussion on ductwork noise transmission from Acoustic Fields highlights crucial aspects of HVAC system acoustics. The movement of air…

Great build plans. thank you Denis

You must use absorption. Never place a chair against a wall.

A friend and I built several diffusors using these plans and they turned out absolutely beautiful. Very good instructions and…