Industrial Noise Control

Industrial noise control is a complex subject. With industrial noise control, we have many noise sources within one room and they all can have different amounts of noise and that noise can be at different frequencies. Workers that work in buildings where noise levels are high can be subjected to levels that are unhealthy due to hours of exposure over a workweek. There is a government organization called OSHA that regulates noise exposure to workers. They have guidelines on frequency and amplitudes and time periods workers can be exposed to the noise. Causes of noise can be machines, heavy equipment, HVAC systems that move air throughout the buildings workers spend time in and perform their specific job functions.

Industrial Noise: https://en.wikipedia.org/wiki/Occupational_noise

OSSA: https://ohsonline.com/Articles/2007/09/Industrial-Noise-Control.aspx?Page=2

Measure Noise

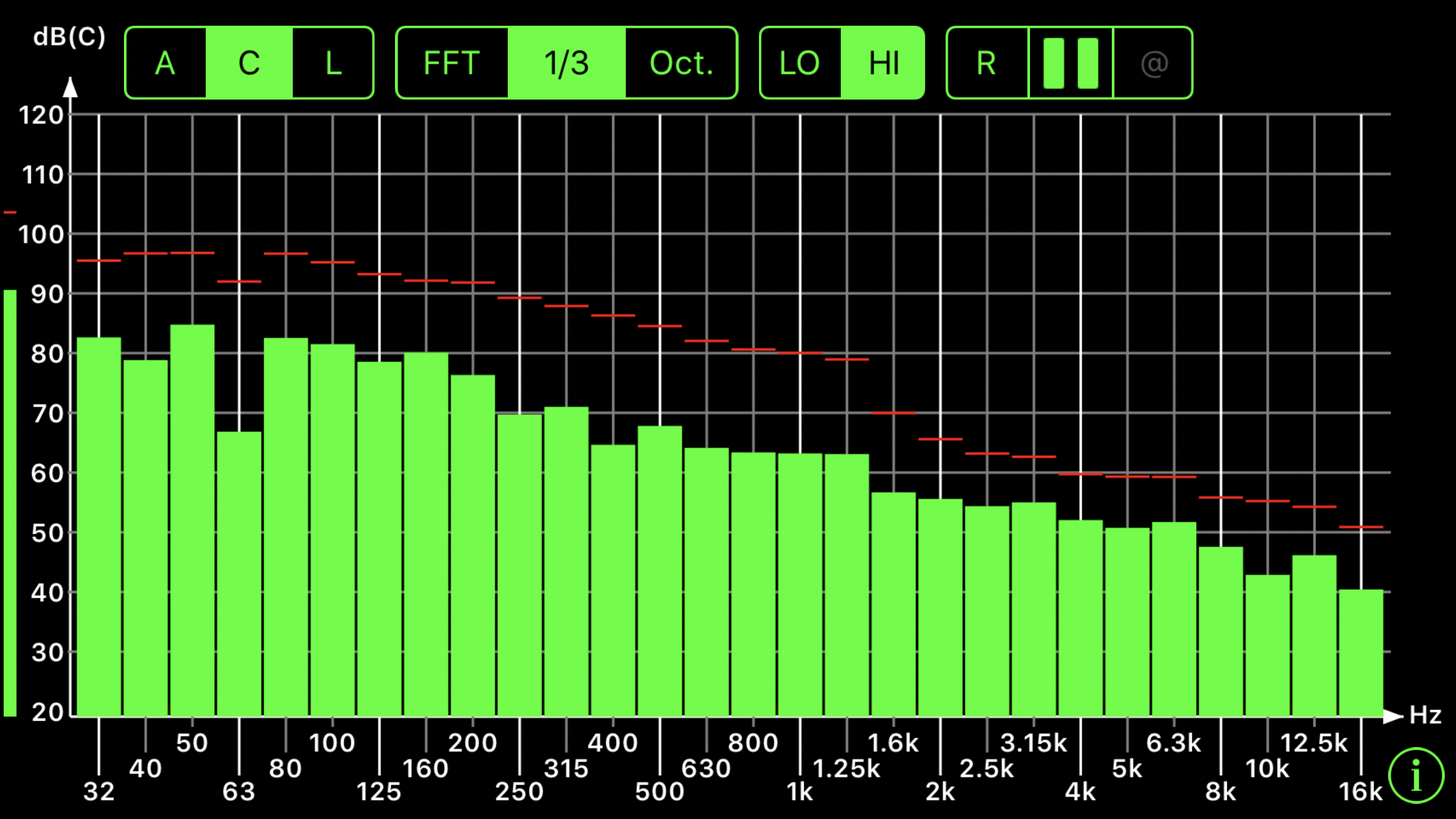

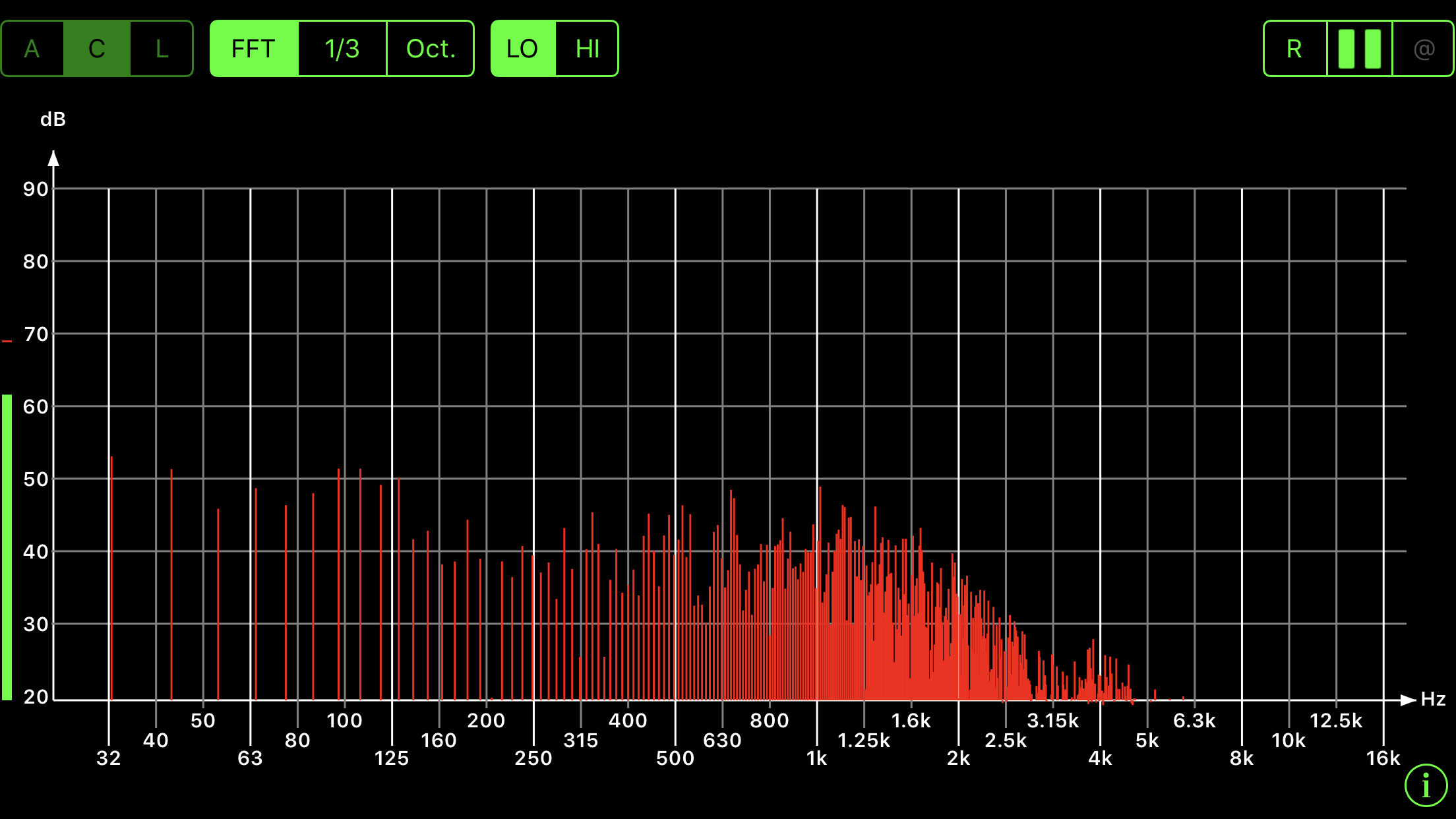

The first task we must perform with any noise issue is measuring the noise. All sound has a frequency and amplitude. Frequency is like a color. Every noise issue is a series of colors. Each color can represent a single frequency. Noise is a mosaic of colors that are composed of many frequencies. The goal of any noise measurement is to define each frequency or color that is contributing to the noise. Colors or frequencies are grouped together in octaves. Defining the noise makes industrial noise control much easier since the treatment types we need to reduce the transmission of the noise is dependent on the frequency and amplitude (strength) of the noise.

Frequency Defined: https://en.wikipedia.org/wiki/Frequency

Octave Defined: https://en.wikipedia.org/wiki/Octave

Every frequency is grouped into an octave. An octave comprises 8 frequencies. We can measure both the octave and the frequencies that compose each octave. We use an RTA real-time analyzer to measure the octaves and an FFT to measure each individual frequency within that octave. We also need to measure the strength of each color. as in most pictures, there is one color that dominates over the others. Most frequencies below 100 Hz. are the strongest since they represent waves of energy that are long. Longer waves of energy like ocean waves are the most difficult to deal with because of their length and strength. Middle and high frequencies like voice are shorter in length and are usually less powerful than waves of noise.

RTA: Real-Time Analyzer

FFT: Shows Individual Frequencies

Noise Types

We have noise the emanates from inside our rooms which are produced by machines and humans. We also have the noise that occurs within our rooms and migrates through our walls to the outside or adjacent structures. Both of these noise types require different treatment objectives. The noise created from inside our rooms that travels outside must be dealt with barrier technology. We build a barrier between our noise room and the outside or adjacent structures. The noise that is produced within our rooms must be absorbed using the proper rate and level of sound absorption technology. If the noise within our rooms is low-frequency noise then we must use a sound absorption technology that deals with the noise at lower frequencies. If the noise in our rooms occurs above 100 Hz. we can use sound-absorbing technology that is designed frequencies above 100 Hz. This is the reason we must measure our noise that occurs both inside our rooms and the noise that occurs within our rooms and is transmitted outside of our rooms.

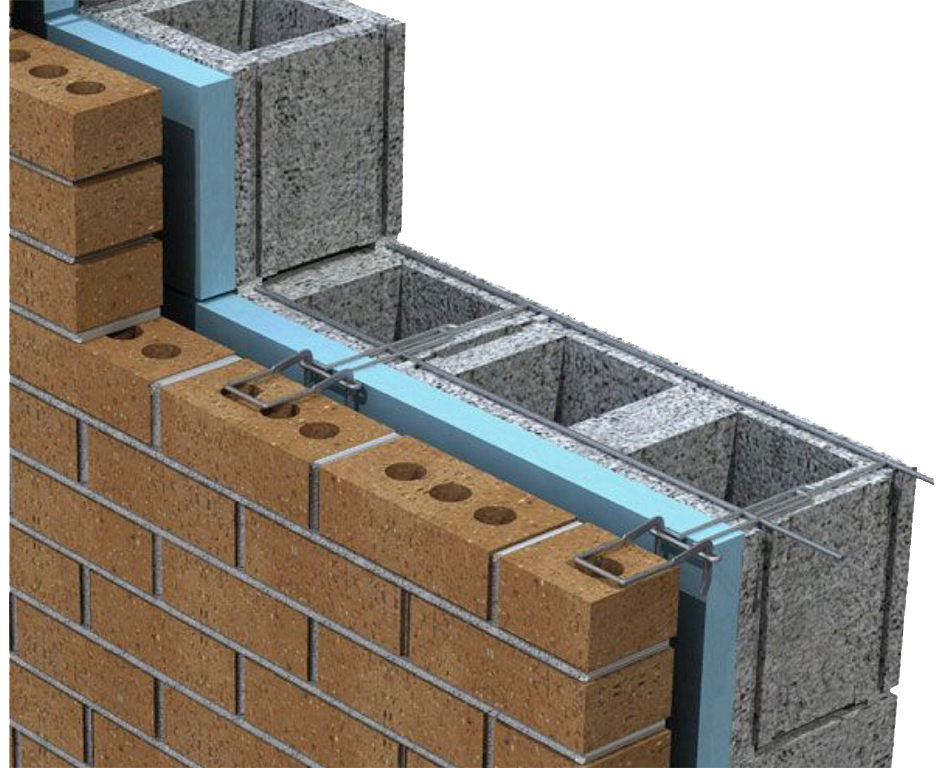

Barrier Technology

To treat the noise that is created within our rooms from entering structures outside or adjacent to our rooms and to keep outside noise from entering our rooms, we build a barrier. A barrier is a frequency-dependent structure that we build between a noise source and ourselves the receiver. Its materials and construction methodology are based upon the frequency and the amplitude of the noise. If we are going to have any industrial noise control we must quantify and qualify through measurement. Barriers come in all sizes and densities. Lower frequency noise requires concrete and steel. Middle and higher frequency noise issues may be able to be resolved with a simple wood-frame structure. Our noise measurements will tell us what direction to go in the barrier design. No guessing allowed. If you guess with the noise you will guess wrong and you may have to tear down what you have guessed at and start over from scratch.

Low-Frequency Barrier Technology

Sound Absorption Technology

Low, middle, and high-frequency noise within our rooms can be managed with the proper absorption technology. just like the noise that moves through our walls, the noise inside our rooms comes in many colors. We must measure first, design the proper type and amount and then decide how much surface area we need to cover to reduce the noise levels within our rooms down to a level acceptable by OSHA. Lower frequency energy generated by machinery such as compressors needs one type of absorption technology. Noise generated from voices and other machine types takes another sound absorption type. This is another reason we must measure the noise so we can determine the type of treatment required, the amount of that treatment type, and the proper positioning of that chosen treatment.

Acoustic Fields Foam: https://acousticfields.com/product/foam-ladder/

Middle and High-Frequency Absorption Technology

About Us At Acoustic Fields: https://acousticfields.com/about/

One of the most informative articles about industrial noise control, really amazing information.