Let’s talk about how to build a bass trap. Alright, first off let’s define some terms. There really is no such thing as bass trap, okay? Bass or low frequency energy is not trapped by anything. I have built structures. Three walls on separate foundation, 8 inch poured concrete thickness of the walls with air space between each wall remembering on separate foundation. And I’ve still had 30 cycle bleed through that.

So we don’t trap low frequencies. We manage them, okay? We try to get as much absorption as we can in the smallest amount of space. Now, we all know from my past videos that there’s 3 types of low frequency absorption. There’s

- Diaphragmatic

- Helmholtz

- Membrane

Membrane is the cousin or brother so to speak of diaphragmatic and Helmholtz is a more specific, frequency-specific resonator that takes special design processes in measurements.

So we like to stay with the membrane and the diaphragmatic. We like the diaphragmatic because you get the most horsepower per square foot of any of the 3 technologies. The other side of the coin with that is they’re very heavy and there’s a lot of pieces in the build. So let’s look at a cross-section of one of those diaphragmatic absorbers and ours in particular.

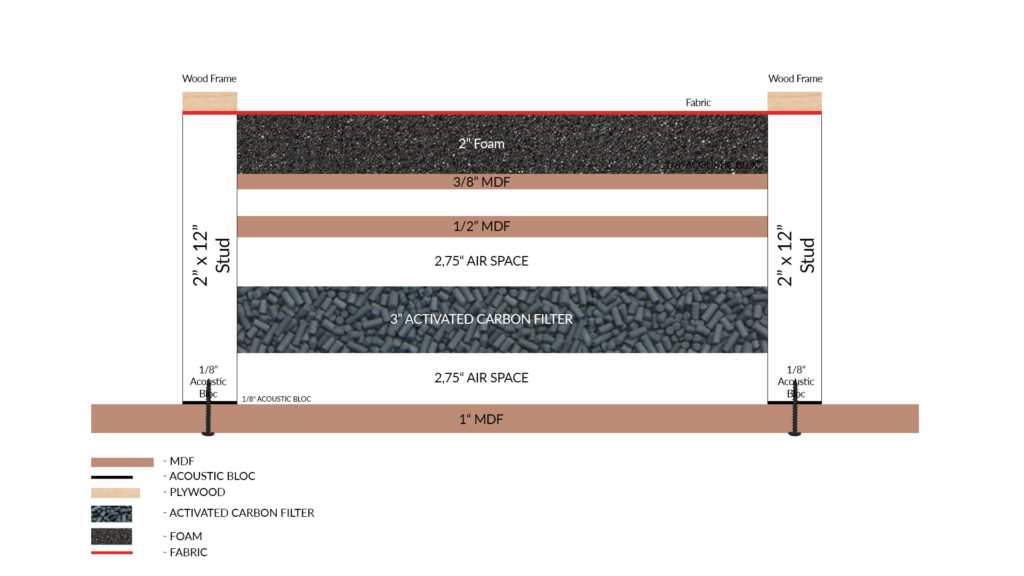

We have 3 main parts to our bass trap (diaphragmatic absorber). We have the front wall, we have the cabinet and then we have the internal cabinet fill. And you can see in this diagram we have the cabinet, we have the two front walls which are out of phase with each other. Those slow the low frequency pressure down. As the low frequency pressure enters the inside of the cabinet, it is then in a lower pressure area so we have absorption occurring. And then some completely leaves the cabinet, it doesn’t get treated at all.

So it’s this balancing act between cabinet, dual front wall and internal fill material. So the internal fill material on our low frequency absorbers is our carbon technology. Now we offer both. You can license the carbon and buy the carbon from us, build your own cabinet, build your own front walls and all of those issues.

The key to diaphragmatic absorption really is density. The cabinet of the bass trap has to be a certain density, the internal fill material has to have a certain absorption coefficient and the dual front walls have to have a certain density to correspond with the density of the cabinet. The other factor in building a bass trap is to have the maximum depth of the cabinet for the resident frequency that you’re trying to design for. So anyone can build a box that will absorb 40 cycles worth of energy. The key is how much of that 40 cycle energy are you getting in your box. And that’s where the internal fill material comes in, the dual front wall construction and the density of the cabinet.

Hope all this helps. We offer a DIY series on our website and you can build your own and we’ll be happy to assist you with the process. So if you’ve got some carpentry skillset, please, you can do this. If you have a table saw you can build these cabinets and we can help you if you run into any problems.

—

This is an unedited transcript from our video series from Acoustic Fields. There will be some errors in grammar and sentence structure that occur during this translation process.

For complete understanding and comprehension, please view the video which is included in this text. For any additional information regarding this topic or others relating to room acoustics, please contact us directly at:

P: 520 – 392 – 9486

The discussion on ductwork noise transmission from Acoustic Fields highlights crucial aspects of HVAC system acoustics. The movement of air…

Great build plans. thank you Denis

You must use absorption. Never place a chair against a wall.

A friend and I built several diffusors using these plans and they turned out absolutely beautiful. Very good instructions and…