Today we’re going to talk about barriers. There’s a lot of confusion, and we get it from clients all the time every day. We really need to discuss barriers and what their purpose are. If we have an ideal situation in our rooms, we have rooms within rooms. This outside layer is called the barrier. Another term for it is a shell. In acoustics, a lot of engineers call it the shell. Barrier technology is the shell of our room.

Now what does the shell of our room do? Extraneous noise that tries to get in our room, hopefully the shell is designed well enough that it keeps that noise to a minimum. It also, any noise generated in the room, should be kept in the room. There’s a ratio of rigidity versus flexibility that has to be maintained between the shell. You got the idea: rigidity versus flexibility that has to be maintained for good quality sound inside your room. We’ll get to that in another video.

We have the shell or the barrier. That’s to keep extraneous noise out, and also any noise or sound, or music hopefully, that we’re generating within the room, keep it within the room. We use barrier technology to do that. We need to distinguish between that and treatment inside. The barrier keeps noise in and keeps noise out, but treatment, diffusion and absorption, is the processes that we use inside the room to manage all this energy that’s inside the room. Two different areas: barriers and treatment. Barriers are shells, treatment for the inside.

Shells come in two flavors: those that work below 125 hertz and those that work above 125 cycles. Completely different approaches to the build, completely different results in terms of how much energy gets through and how much energy stays out. There’s a common technique out there that people use. It’s that double layer of drywall with green glue and resilient clips. Good technology for above 125 cycles. Not so good technology for below 125 cycles. You have to make sure that you’re building the correct barrier to match the frequency of issues and problems that you have in the room.

Had a client the other day built a home theater room, used this method, and he has four subwoofers in the room. He’s very unhappy that the low frequency energy is leaving the room and going out into adjacent rooms. Well, he was happy with the mids in the highs. He would be because anything above 125 cycles, the drywall, glue, and clips did a good job for him. Anything below 125 cycles, it didn’t work. That’s why you have to be very careful. You have to quantify the problem, qualify the solution. Quantify the problem, qualify the solution: two different paradigms you have to look at.

The literature is full of drywall, green glue, and resilient clips. If I see that again I’m going to pull my hair out. It’s a good technology. There are better. I have some different technologies that we use that work a little bit better for the same price point, but it’s no good below 125 cycles. If you’re a really full range system with full range energy requirements, full frequency response, be very, very careful using that technology. It’s cheap, cost-effective, but you get what you pay for.

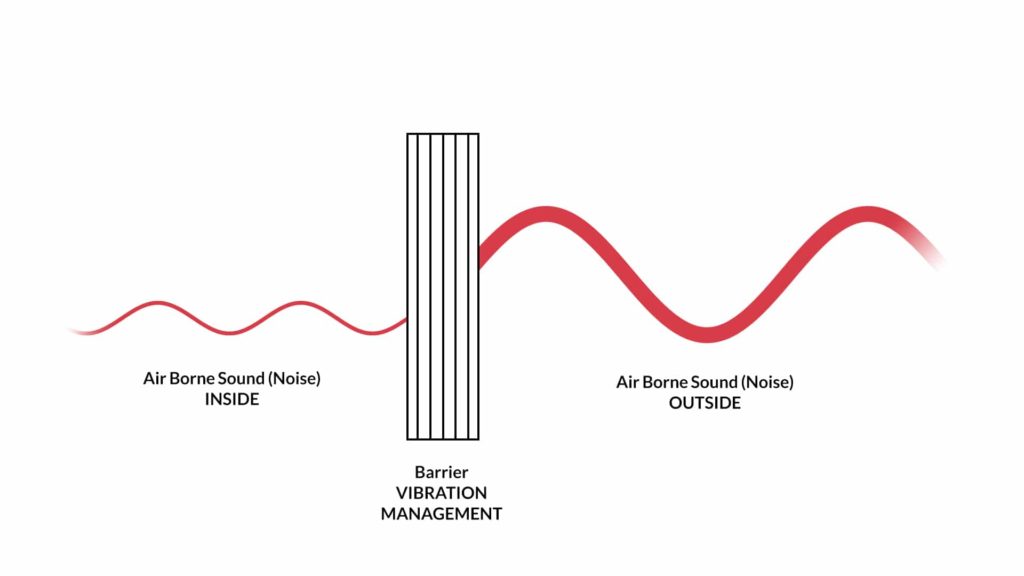

Airborne versus structural. We have to realize that we have airborne energy, and then it’s going to strike a structure. Once it strikes a structure, its signature changes. It becomes more of a mechanical situation. We have a vibrational significant and we have airborne energy, so two different approaches in our barriers that we must use. You have to be very careful of what you’re doing. First we got to know how much energy, what frequency it’s at, what’s the magnitude of our problem, what frequency is our problems at, and then we can construct the right barrier. Obviously, we want to build a barrier that does the job without overkill, without spending too much money, so we have to be careful.

Barriers are very critical in their design and build. I’ll give you an example. We built an 8″ poured concrete well separated by 6″ of air space and another 6″, I believe, poured concrete wall. We still measured some energy getting through it at 30 and 40-50 cycles. You have to be very careful about what you’re doing and what you’re building. You have to measure, quantify, and then qualify. Always know what your problem is, and then there’s a solution that you can use to fix the problem. If you don’t know what the frequency of concern is, it’s going to be difficult to build the right barrier technology.

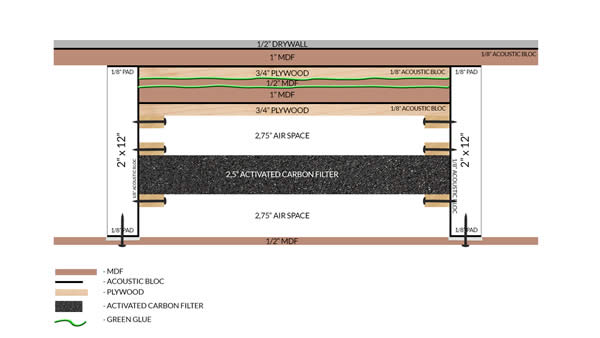

It’s a layered approach. Barriers are layered because we’re dealing with a different vibrational energy versus airborne. It’s a little complicated. You have to have some experience. We’ve built hundreds of rooms. We’ve actually put accelerometers on the walls and tested the vibrational levels of these so we have really good ideas of what materials work with other materials to give you the highest impact.

Graphic five shows us that we’re taking airborne energy and it’s striking our barrier. Then it becomes vibrational energy. The approach that we have to use is different than absorption and diffusion treatment on the inside of the room. What approach do we use? Graphic six shows us that it’s a layered approach because we’re trying to reduce vibrations. We provide a series of layers that the vibrational energy has to go through. We select the correct densities of those layers. We arrange them in the correct way. Then we’ll achieve a pretty good result at the end.

The discussion on ductwork noise transmission from Acoustic Fields highlights crucial aspects of HVAC system acoustics. The movement of air…

Great build plans. thank you Denis

You must use absorption. Never place a chair against a wall.

A friend and I built several diffusors using these plans and they turned out absolutely beautiful. Very good instructions and…