The word acoustic has entered our lexicon and has attached itself to everything like a barnacle to a ship. It is even in our company name Acoustic Fields. We have acoustical fabric, acoustic drapes, acoustic you name it. What does the word acoustical mean? The problem with all of this improper usage, we have distorted the real meaning of the word acoustical. Companies use the word acoustical in order to justify a price increase that may or may not have anything to do with acoustics. However, acoustical fabric is one combination of adjectives and nouns that does have real meaning as a certain fabric type relates to function. There are some fabric types that work best for air flow and some that do not. The term acoustical fabric describes a fabric that allows a large percentage of air flow to go through the fabric. It is air flow or as we say in physics, molecular velocity, that we desire when it comes to an acoustical fabric type. Let’ examine the function requirements of acoustical products and the meaning and use of acoustic fabric will become clearer.

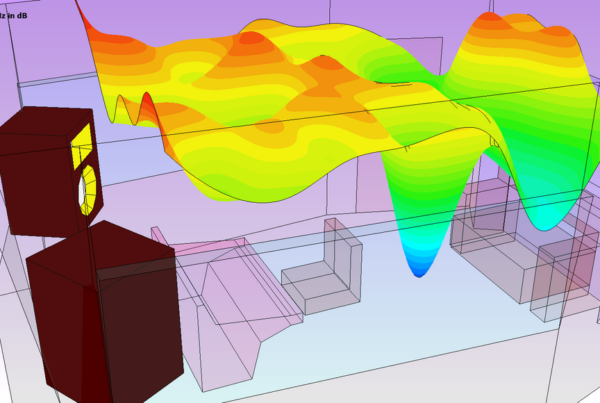

Sound energy comes in two flavors. We have waves and rays of energy. Think of waves of energy as ocean waves. They are large powerful energy waves that oscillate throughout our rooms in cycles or frequencies. Waves are low-frequency energy that represent what laymen call “bass”. It technically is frequencies below 100 Hz. Rays of energy are like sunshine. They are straight, shorter, and thinner. They represent our middle and high frequencies that are found in voice and music. Waves of energy require one absorption treatment type to mitigate. Rays of energy require a completely different treatment type than wave energy. Wave energy is a pressure based energy, remember ocean waves. Low-frequency pressure waves strike an absorber and everything that happens in the absorption process is pressure based. The absorber starts moving or vibrating in sympathy with the pressure that is exerted upon it..Ray energy works on air flow across the surface of an absorption material type. This is where acoustical fabric comes into play. Acoustic fabric is a cosmetic material type with different colors and textures that allows for air to move through it. https://www.acousticfields.com/product/acoustic-panels/

The process of air moving through an acoustical fabric is termed air permeability. https://acadiantextiles.com/news/air-permeability/ Since ray energy absorption works on air flow across the surface area we need a fabric that will “breath”. We will need a fabric that if 100 % of the sir strikes the fabric that at least 95% goes through the fabric. This 5% reduction in air flow due to the fabric density will not have a large impact on the absorption of the technology when it comes to middle and high frequencies. The acoustical fabric must have an air permeability of no greater than 5%. If the fabric restricts more than 5% then the performance of the product will deteriorate and be compromised to the point where the fabric becomes audible. There are only a few companies that offer true acoustical fabrics due to these air permeability requirements. You want to stay with Guilford of Maine as your first choice. They offer over 50 different colors and textures all with 95% + air permeability ratings that you must use these fabrics. https://www.guilfordofmaine.com/acoustic

Middle and high frequency energy travels through the air like sunshine rays. It strikes all the objects that are within our room. This is why in any critical listening environment you must be sensitive to what material types you have in your room. Sound takes on the characteristics of the materials that it strikes. If it strikes glass, you get a harsh,squeaky glass sound. If the sound energy strikes wood, you get wood sound which is smoother and more natural. As our middle and high frequency energy moves through our room, it will strike all four walls and ceiling. These surface areas will then produce a series of reflections. If you add up all the reflections from the room surfaces, you get what we call in physics reverberation. Reveneration is the time sound stays around within the room after it has been sung or played. It is not echo. Echo is the repeating of the same signal over distance. Reverberation has a negative impact on speech and music. With high reverberation times, you find yourself saying “what? ” or “sorry?” all the time.

To manage reverberation or the reflections from our wall surface areas, we use sound absorption. Not low-frequency sound absorption but middle and high frequency sound absorption. These technologies can take many forms but the most economical with predictable performance parameters is open celled foam. Foam is lightweight and relatively inexpensive to install and treat rooms. You will require a 60 – 70% surface area coverage to achieve a satisfactory reverberation time that will work for most usages. Our Studio Pro Foam took 8 years to develop at a cost of over 2M. It was designed specifically for music and voice. Most foams that are currently in the marketplace were designed for noise. Their design goal was to absorb as much energy as they could in every surface area of the foam. This is not what you want for music and voice. Music and voice require particular rates and levels of absorption in order to sound natural and not too “dead”. https://www.acousticfields.com/product/acoustic-foam/

Use whatever floor type suits your usage. Carpet should have a carpet pad under the carpet. Hardwood floors should have…

Hello. This article mentions choosing a sound absorbing carpet and a pad. Could you please give examples of products? I…

All noise must be measured for frequency and amplitude. The barrier design chosen to fix the noise issue is dependent…

Hi, Really interesting article. I've just had a prototype water filtration and softening (using filters, not salt) system installed in…