There is no such thing as acoustic wood paneling. Manufacturers use the word acoustic to play upon the ignorance of the layman. In order to have the word acoustic applied to any product or technology, it must either absorb or diffuse energy. If it can’t do either, then you are paying for something that does not work. Acoustic wood paneling is another example of mislabeling and misleading in order to make a sale. It is amazing to us how companies are allowed to advertise a product and call it acoustic wood paneling. Paneling will not absorb energy. It will not diffuse energy since it can’t meet the strict requirements that a technology is held to in order to qualify as a diffuser. Don’t be tricked into buying a product that is labeled acoustic wood paneling.

There are only two processes that occur that deserve the word acoustic and none of them use the term acoustic wood paneling. There are two ways a product can impact sound. It can absorb sound energy. It can diffuse energy. Those are the only two processes that are used when you see the word acoustic. If it absorbs energy you should be able to see the rates and levels of absorption produced by the technology. Diffusion technology is another process that has been misapplied. In order to qualify as a sound diffuser, you must be able to satisfy 5 rigid criteria that involve sound fields that have certain energy decay rates, reverberation times, and many other issues. Suffice it to say, most products that are labeled as diffusers within the marketplace are not able to perform as a diffuser must. https://en.wikipedia.org/wiki/Sound_diffusion

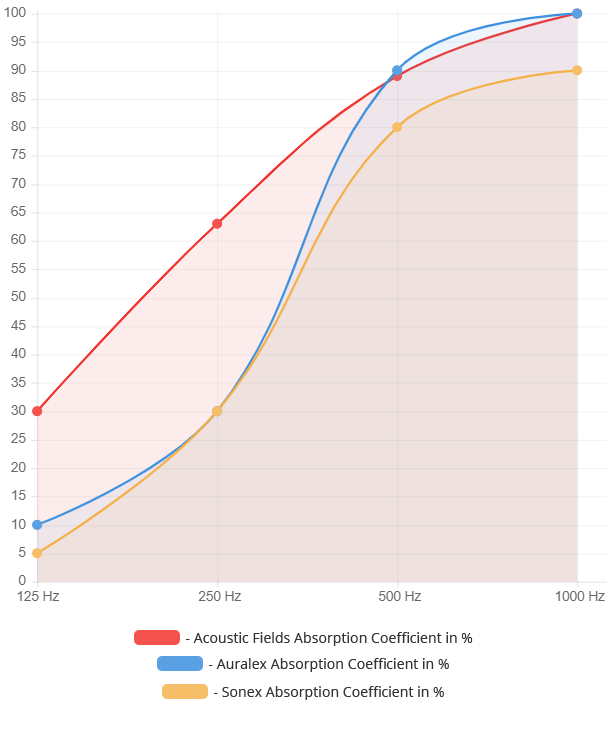

Absorption is a process that is produced by friction. Air moves across the surface area of the material type and friction is produced. Friction produces heat and this energy transformation produces absorption. Any technology that is described as a sound absorption technology must have a rate and level of absorption. The rate of absorption is how much energy the technology absorbs at each frequency or octave band. The level is how low the technology works down to. With sound absorption technology the depth of the technology will determine how low the product will begin to work at. For example, our 2″ piece of foam at acousticfields.com begins absorbing at 125 Hz. If you double the thickness, it starts absorbing at 100 Hz. If you add another 2″, you can achieve an absorption level of 90 Hz. https://www.acousticfields.com/product/acoustic-foam/

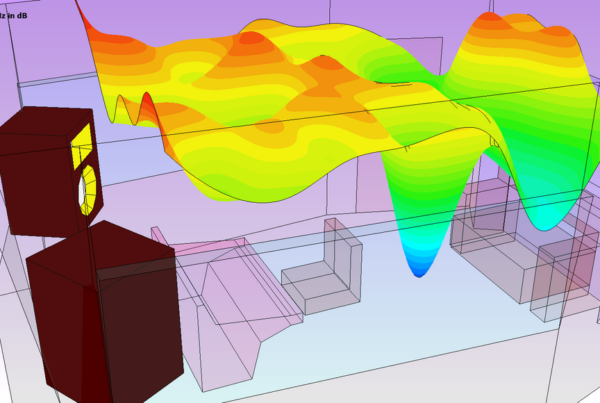

We have two frequency ranges of energy that must be dealt with in any room. We have low frequency pressure issues and we have middle and high frequency reflection issues. Low-frequency energy or “bass” requires a certain type of technology to treat.https://www.sciencedirect.com/topics/engineering/sound-absorption. There are three main types of low-frequency absorption technologies. We have Helmholtz, membrane, and diaphragmatic. Of those three technologies, diaphragmatic is the most powerful per square foot. With low-frequency energy, you must use one that has the power to absorb long waves of energy. Our technology is the world’s most powerful and you must use enough square footage of coverage in order to treat pressure issues. Low-frequency issues are produced by the four walls and the floor to ceiling dimensions. All of these surface areas will require a certain amount of coverage in order to manage the pressure issues produced by their dimensions.https://www.acousticfields.com/product/acda-10-studio/

Reflections are a middle and high frequency issue. They require a completely different technology to treat lower frequency issues. Reflected energy can be managed with open celled foam technology. It is lightweight and inexpensive. care must be taken to use open celled foam that is designed with the proper rates and levels of absorption for music and voice. Music and voice are unique in their resolution requirements. You must use an absorption technology that has the proper rates and levels of absorption for music and voice. Our Studio Pro Foam took us 8 years to develop at a cost of over 2 million. dollars. https://www.acousticfields.com/product/acoustic-foam/