What is soundproofing for drums. Let’s examine that phrase and break it down into components that we can look at individually. First, there is no such thing as sound proofing. There is definitely no such thing as soundproofing for drums. The wood “proof” is misleading. There are no absolutes when it comes to noise transmission. Noise can go through steel and concrete. What chance do rooms with wood frames have? Drums are the second largest energy producing source next to a gong. The energy from a kick drum can be 30′ long and 15′ high. It oscillates through our room like an ocean wave and keeps coming and coming and coming. It never stops and it will eventually excite the room structure so much, the room will start moving in response to the sound pressure filling the room from just the kick drum alone not to mention the snare and the tom. Soundproofing for drums does not exist. We must manage and mitigate all noise from any music room but we must pay particular attention to the lower frequency energy transmission since it is full range sound and very powerful. We must attenuate enough noise that the noise levels we produce within the room are lower than the neighbourhood noise levels.

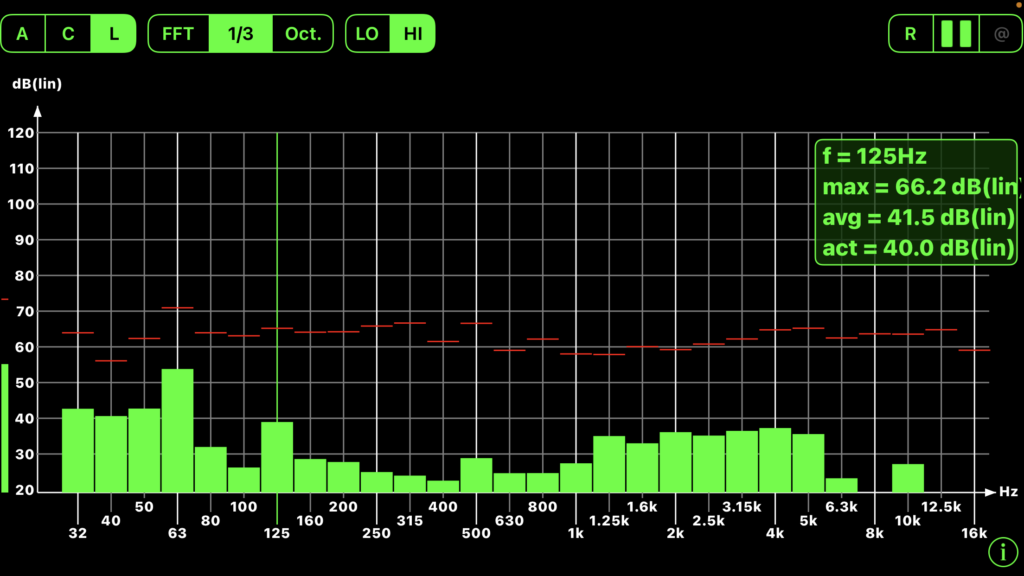

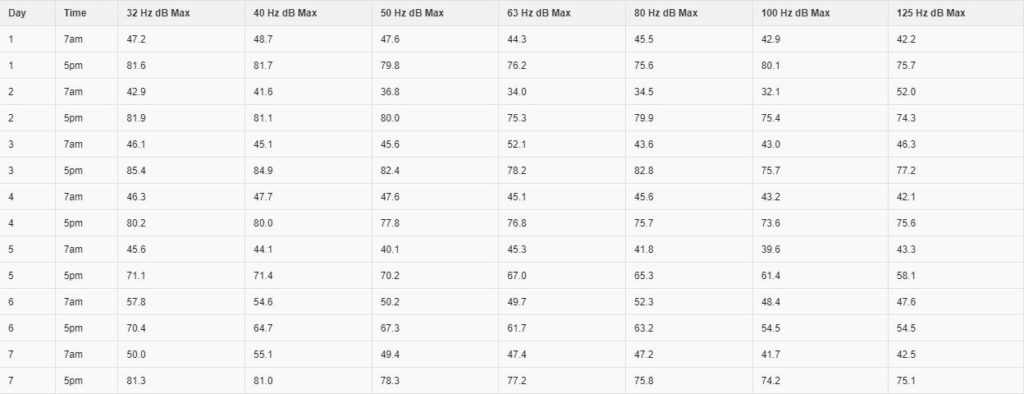

We have two types of noise that we must be concerned about in soundproofing for drums. We must be concerned with the noise in our drum room leaving the room and disturbing others. We must also be concerned with the noise from others coming into our drum room and bothering us. Noise levels in neighborhoods fluctuate dramatically. If you measure noise during the day when human activity is at its highest and then you examine that same neighborhood at 2 am in the morning, you will see that there can be a drop of up to 40% in neighborhood ambient noise levels. If you’re playing drums in the daytime, you may not disturb anyone in the neighborhood since the noise levels in the neighborhood will contribute to masking your drum noise. If you play drums at the same pressure levels at 2 am in the morning, the police will be knocking at your door with a noise complaint. This is why it is so important to measure the noise frequency and amplitudes in the neighborhood so you can see what the pressure levels are you must isolate from. Noise is a two way valve. It can leave your room but it can also enter your room. Noise transmission is all about reducing the vibrational signature of the noise that is moving through structure. https://en.wikipedia.org/wiki/Acoustic_transmission

At Acoustic Fields we have a noise measuring process where you download our apps to your cell phone. You follow our instructions and take noise measurements over a seven day time period. We need to know the noise levels everyday over a whole week so we know what we are competing with and thus what barrier or wall type we need to build. The barrier wall we will build and the materials we will use in the barrier are directly related to the frequency and amplitude of the neighborhood noise and the frequency and amplitude of the in room noise that can be transmitted to the neighborhood. The barrier construction materials and type are built upon a ratio of the outside noise trying to get in and the inside noise trying to leave the room. Every material type, density of that material, and the construction methodology used is based upon the noise measurements. With noise, you must measure since we do not want to spend more than one dollar more than we have to mitigate the noise transmission issue. Since barrier technology is a permanent build, we will never recover the barrier expense since it will stay with the structure when we leave. https://www.acousticfields.com/sound-barrier-technology/

Once we have our noise numbers recorded over seven days, we can examine the minimum pressure levels along with the maximums. Everyday and night will be different. We want to look at the maximum pressure readings and design for the maximum pressure we will face during the day or night that has the largest pressure reading. If we build a barrier to stop the lowest frequency on the loudest day, we are good with other readings that are not as high. If we show large amounts of noise energy below 125 Hz. then we will need a different barrier type than if the noise is above 125 Hz. With the noise within our drum room, we will have full range noise energy to deal with. The kick, tom, and snare all produce energy below 125 Hz. To minimize the noise transmission out of the room, we will need to focus on the frequency and amplitudes below 125 Hz. This will require a barrier type that has multiple layers of materials that are arranged in a specific order to treat the lower frequency issues all drummers face. If you have a drum room and want to be able to use it whenever you want to, you must be aware and measure the neighborhood noise levels. Simulating the frequency and amplitude within the drum room is easy. What is unknown and must be known is how noisy the neighborhood is. The last thing you want is a restricted usage for your drum room. You want to be able to use your room whenever you need to. https://www.sciencedirect.com/topics/earth-and-planetary-sciences/noise-barrier

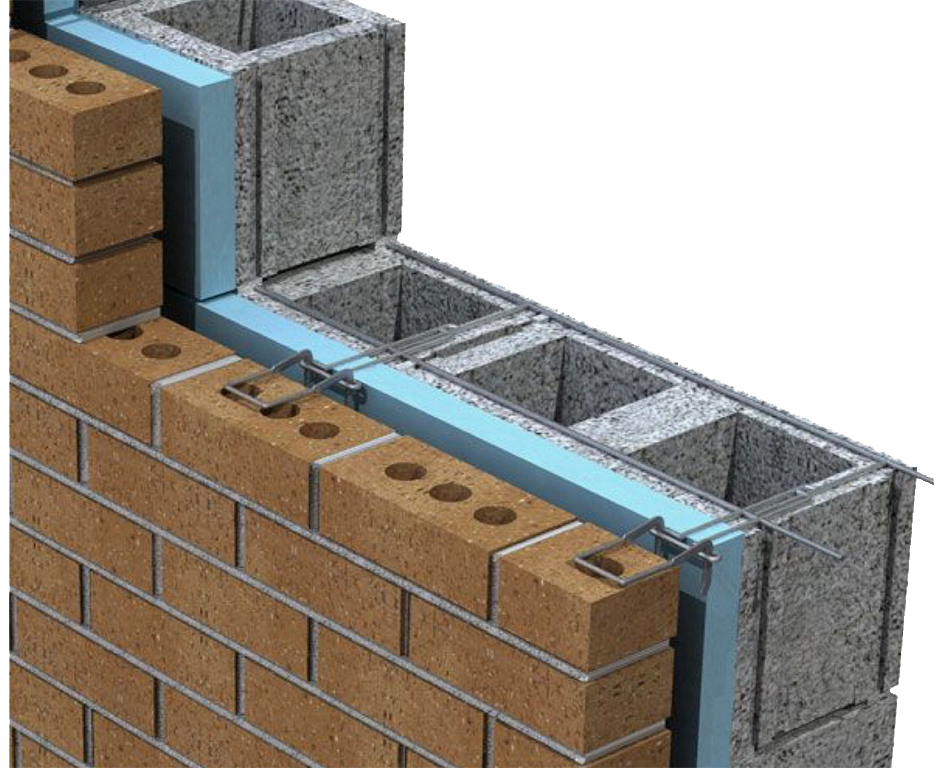

Most drum room barriers we design are between 6-10″ deep for a drum room. These drum rooms are usually found within the garage area of the house with neighbors close by. We build a lot of rooms in Los Angeles and in California, people live very close to each other. The need for noise management is critical since most municipalities are very serious about enforcing noise ordinances. We design barriers that have different layers of materials arranged in a certain order or sequence. We use standard construction type materials. There is nothing exotic in the materials used within our designs. Any certified contractor can follow our build drawings with the associated material lists. There are no exotic construction techniques required and planning and building can function just like a standard build. We usually build drum rooms on concrete slabs. We specify a 6″ thick slab rather than a 4″. The extra 2″ of concrete mass will reduce floor vibrations by up to 26%.

Once we have the noise issues addressed and the proper barrier built, we can design the low frequency absorption to manage the energy within the drum room. If we can absorb some of the energy within our drum room, we have less energy that will be transmitted out of our rooms. We have processes where you can build the low frequency management into the walls themselves along with the barrier technology we described. It is called our CAW which stands for carbon Absorbing wall. It is a process where we convert each stud space into a diaphragmatic absorber allowing us to tune the low frequency pressures within our drum rooms every 14 1/2″ between each stud space. This allows us to manage the frequency at every room location and the amplitude or strength of that frequency at that given wall location. https://www.acousticfields.com/carbon-absorber-wall/ Once we have managed the lower frequency pressure issues, we can then treat the middle and high frequency issues more economically with open celled foam. For those that want to take their drum rooms a step further, we can use diffusion which will make the drum room sound twice as large. https://www.acousticfields.com/product/drum-platform/

The discussion on ductwork noise transmission from Acoustic Fields highlights crucial aspects of HVAC system acoustics. The movement of air…

Great build plans. thank you Denis

You must use absorption. Never place a chair against a wall.

A friend and I built several diffusors using these plans and they turned out absolutely beautiful. Very good instructions and…