This blog has been updated to reflect new information in regards to sabins and sound absorption coefficients, updated on 11/11/19.

Here’s my video explanation and below is a more detailed written discussion.

The Relationship Between Sabins And Sound Absorption Coefficients

Sound absorption is defined, as the incident sound that strikes a material that is not reflected back. It is the ratio of absorbed energy to incident energy. An open window is an excellent absorber since the sounds passing through the open window are not reflected back. This process of having the window open makes for a poor sound barrier. A painted concrete block is a good sound barrier but will reflect back about 97% if the incident sounds striking it. An open window works well for sound absorption since the sound leaves and never returns. However, noise entering and leaving the room sees it as an escape or entrance, It is barrier to nothing not even air.

Sound Is Vibration

When a sound wave strikes an acoustical material the sound wave causes the fibers or particle makeup of the absorbing material to vibrate. This vibration causes tiny amounts of heat due to the friction and thus sound absorption is accomplished by way of vibrational energy to heat conversion. The more fibrous the material is the better the absorption since we have many fibers for the air to contact and cause friction by moving over and through them. Denser materials are less absorptive at middle and high frequencies but more at lower pressure frequencies. The sound-absorbing characteristics of acoustical materials vary significantly with frequency. In general, low -frequency, sounds are much more difficult to absorb because of their longer wavelengths.

Absorber Thickness

For the vast majority of conventional acoustical materials, the material thickness has the greatest impact on the material’s sound-absorbing qualities. While the inherent composition of the acoustical material determines the material’s acoustical performance, other factors can be brought to bear to improve or influence the acoustical performance. Incorporating an air space behind an acoustical ceiling or wall panel often serves to improve low-frequency performance. Designing cabinets that have air space and material fillers in that air space will go a long way to improve overall cabinet absorption rates and levels.

Here is the diaphragmatic absorption process in greater detail:

https://acousticfields.com/about/

Examine middle and high-frequency open-celled foam in this link:

https://acousticfields.com/product/acoustic-foam/

Reverberation Vs. Impedance Tube

There are two methods of measuring the amounts of sound absorbed by various materials. One is the reverberation method of W. C. Sabine, in which a specimen of the material to be tested is mounted on the walls of a reverberation chamber and the coefficient of absorption is deduced from the effect which the presence of the specimen has on the rate of decay of sound in the chamber. The other method consists in placing the specimen at the end of a pipe down which sound-waves are made to pass. Measurement microphones are placed at both ends of the tube. The reflected and incident waves interfere, and the coefficient of absorption is calculated from observations made on the interference pattern within the pipe. Here is a link for impedance tube testing:

http://sine.ni.com/cs/app/doc/p/id/cs-654

Sabins

A Sabin is actually a scientific term for a unit of measurement of sound absorption. It is the basic unit of measurement that has been formulated and calculated by Wallace Sabin over a hundred years ago. Riverbank Labs, now Alion Research is the lab that was created by Wallace Sabin for testing the amount of absorption material has and is then assigned a value in Sabins. It is calculated by using one square foot and assigning a maximum value of 1.00 if the material tested has 100 % absorption of that particular frequency. If you are using the metric system, you would use one square meter as your reference size and it would yield a value of 1.00 also if 100 % absorption occurred at any chosen test frequency.

Sabins Measured

In summary, a Sabin is a unit of measure and any material tested will produce so many Sabins per square foot or per square meter depending on your standard of reference. If a square foot of any given material had a Sabin count of 30, you would know that it is equal to 30 sq.ft. of 100 % absorption at that frequency of that test sample. Let’s examine our own Riverbank Test Data to look at these values.

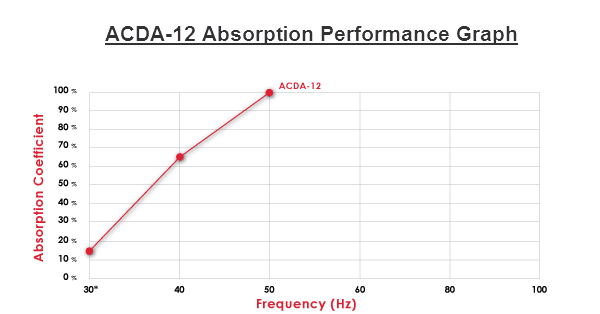

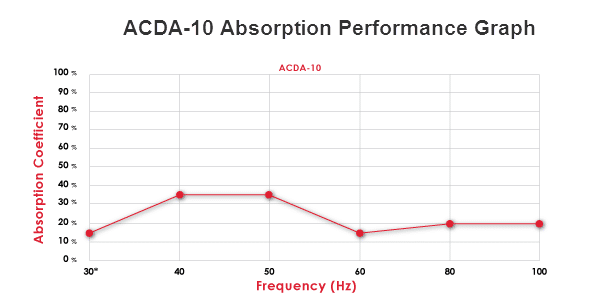

Our ACDA-12 units show at 40 Hz. that our test sample size produced 44.59 Sabins. At 50 Hz., our test sample produced 77.87 Sabins. Following the definition of Sabins was a perfect absorber at 1 sq.ft. receives a value of 1.00, we have almost 45 sq.ft. of 100 % absorption and at 50 Hz. we have almost 78 sq. ft. Our sample size was 72 sq. ft., so we can safely say that 72 sq.ft. of our ACDA-12 units absorbed 100 % of all the 50 cycle energy that was introduced. Let’s look at what the absorption coefficient means.

Here is the full test data report on the ACDA-12 performed by Riverbank Acoustical Labs.

Sound Absorption Coefficient

The sound absorption coefficient is the ratio of reflected energy that strikes our sample size to the amount of energy absorbed by our sample size. It is expressed in terms of 1.00, which is equal to 100 % sound absorption at that tested frequency and sample size. Back to our Riverbank Test Data, at 40 Hz. we had an absorption coefficient of .62. What does that mean?

It means that 62% of the energy at 40 Hz. striking the sample size was absorbed and 38% was reflected back. At 50 Hz., we had an absorption coefficient of 1.08. Obviously, our number can not be greater than 1 so the numbers to the right of the decimal point are due to testing bias. We can use 100 % as our number for absorption calculation and not be discrediting the test data. At 50 Hz., our sample size absorbed all the 50 cycle energy thrown at it during the test.

I hope this explanation helps. If you have any questions please don’t hesitate to call on me as I am always available to help. Feel free to leave comments below and I will get back to you. Be sure to like or tweet this out to other audio friends. If you want to learn more about this subject please sign up for our free room acoustic treatment videos and 150+ page e-book which provide step by step instructions. Get instant access by signing up now.

Thanks,

Dennis

Dear Mr. Foley,

I have the sabine coefficient of absorptions with the gradual increase of frequency so how do I can use in BEM modeling? In the BEM model software accepts only damping factor, reflection coefficient, and admittance. what is the exact relationship between sabine absorption coefficient and damping factor?

Hi Venkat, I am unsure about the relationship between the two variables. Using definition, there seems to be a correlation between the two variables, but I do not know how to program that.

Dear mr. foley,

i wanna design a concert hall.. about for 1500 people .. what will be the sound treatment. how will be control it..thank you…?

Hi Haider, This will all have to be designed to make sure you get the correct coverage in the audience. You must match the speaker array with the audience coverage. You must have the correct Rt-60 calculations to manage reflections and the right amount of everything to make this work the right way. Lets start with the size and volume. Fill out the information in this link: https://acousticfields.com/free-room-analysis/

Dear Mr Foley,

I was just wondering what the reason is for the following question; why does the thickness (of say a foam) material increase the amount of sound absorbed. Is there a formula that exists to model this relationship ??

Hi Teodora, Depth or thickness is related to absorption. The greater the depth, the lower frequency of resonance that can be achieved. Frequencies above the resonant are absorbed, those below are not. Open celled foam composition has come a long way since its inception. Depth increases the lower end resonant frequencies to between 100 – 125 Hz. with open celled foam. Is there a way to model this performance. Yes, there are ways with a little research on the net. Each methodology is specific to the medium you have chosen for absorption. A 2″ piece of open celled foam will absorb at different rates and levels than a 2″ thick drape.

Dear Mr.Foley,

I see a lot of American manufacturers publishing test reports with NRC ratings up to 1,55 and actually being very proud of it.I do understand that you can have some small deviations due to testing bias,but do you have any idea how this could be explained.I also barely see any serious reporting with testing conditions and the actual testing method,including a picture of how they tested the material(with or without air gap..)

In Europe acoustic engineers or consultants wouldn’t even take those reports seriously,but I really try to understand if they use other (accepted?)measuring methods?

Thanks and keep up the good work.

Hi Daniel, I see this on numerous occasions and like you, am at a loss on how to explain it. I understand that some measurements may exceed 100 % due to testing variations and error rates but this 1.55 number is baffling to me.

Dear sir ,

How we can determine the sample size and cut off frequency for reverberation chamber. Is there any relationship equation to determine both of them ?

please can you assist on the simple defination of absoption co-efficient

A, It is the amount and frequency of that amount of absorption for one square foot of surface area of a test sample.

Dear Mr.Foley,

If you used micro-perforated materials as sound absorbents before, what is the optimum perforation ration to get the highest absorption coefficient?.

Is there any correlation equation between normal incidence (impedance tube) and random incidence (reverberation chamber) sound absorption coefficient?

Thank You

H, You must match the technology to the frequency issues you are experiencing in your room. I do not have any experience with micro-perforated materials. Sample size in impedance tube testing is related to reverberation chamber but it is frequency dependent.

Hi I need to design a auditorium , whose surface areas of various parts are known( like ceiling area , stage area , seat area , walls area etc) , I am confused to chose for what frequency should I calculate absorption – 125 Hz or 250Hz or 500 Hz etc. coz there are different absorption coefficients for different frequencies for same material

V, I will need to know much more about your room before I can assist you. Fill out the information in this link: https://acousticfields.com/free-room-analysis/

Dennis:

On other websites, I have seen absorption coefficients quoted as being greater than 1.00. How can this be? Above, you admit it can happen and say it occurs through “testing bias”. What is testing bias and even if it affected the measurement of an absorption coefficient, why would anyone quote a coefficient greater than 1.00?

B, It is part testing bias and part self-promotion to the uninformed. When you see a number greater than 1, just use 1.00.

Thank you for the video explaining the difference between sabins and sound absorption coefficient.

If the sound absorption coefficient of a sample is 0.3 at 250 Hz, and the sample size was 12 sq.m, can I apply this same sound absorption for 1 sq.m also? Does the sound absorption vary with the area of the material used?

S, The rate and level of absorption is constant across the sample size.

Thank you very much Mr. Dennis, I am into central air conditioning. In air-conditioning, the air from the noisy roof top unit goes through a few metres of acoustically lined duct for some noise attenuation before the air enters into occupied space. If the level of absorption is constant across the sample, would you know on what basis do the duct designers decide that they require x meters of liner is required to bring the noise down from 70 dB to lesser.

S, I do not know the processes they use. It would be best to contact someone in that field.

Hello!

I’m looking at different absorption solutions for my recording studio. The problem is that the specifications of the products I’m looking at are measured in m2 Sabins, Sabins/unit and absorption factor. Is there a way to convert those measurements to the same unit so i can compare them?

N, Use standard metric to imperial conversion charts. They are available on the web.

Hi,

I want to design/build some acoustic treatment but I’m trying to understand why acoustically tansparent material is often used in designs when my understanding would be that surely the only important factor would be how reflective the material is (so I suppose in essence the acoustic impedance). Surely if a material will absorb some sound, pass the rest through and reflect no sound that is a better material for covering an acoustic absorber to one which is only acoustically absorbent?

This leads on to my next question, where I’m finding it very difficult to find a materials database which outlines acoustical properties of varies materials in order to choose a material with the best compromise of materials, do you have any suggestions?

There is no such thing as “acoustically transparent materials”. All material types that reduce the air flow across the surface area of middle and high frequency absorption technology types is attenuating at certain frequencies. We have seen movie screens that attenuate up to 8 dB at certain frequencies. That is unacceptable.

Many material types have published rates and levels of absorption. The key is to knowing what rates and levels of absorption work best for your usage. Only experience and testing will provide those answers. My foam technology took 8 years and 2 M to develop. Music and voice are different than noise.

You must first decide on the room usage. You then tailor your treatment types, amounts, and positions to compliment your chosen usage. Not all rooms are multiple usage friendly. Some rooms work for this, some work for that. Once you have determined usage, you then choose room size and volume. You look for room sizes/volume/usages that produce no coincidental modes. Once that decision is made, you can then treat the low-frequency issues first and foremost since the harmonics are the children of the fundamental marriage. Once all low-frequency issues are managed to the best of the space requirements and budget, you move to time signatures of all reflections. Managing the time signature of all reflections will treat the overall Rt-30 / Rt-60 times.

Hi Dennis,

Thanks for all the information you share, I’ve learned quite a lot thanks to you! I have a quick question though, some Acoustic Lighting brands in Europe show the Equivalent Sound Absorption Area in sqm, shouldn’t they be showing Metric Sabins instead? What’s the difference between these two?

Thanks in advance!

Yes, it would be a better basis for performance parameter testing.