Table of Contents

Health Concerns with Rock Wool Panels in Acoustic Treatment

Rock wool panels or any other building insulation type materials should not be used as an acoustic treatment for many reasons. The first reason is for your health. If you read carefully the installation requirements using this material type you will see that the installation of these materials types requires the use of a respirator along with protective clothing to avoid contact with your skin.

If the installation requirements have you in a full body suit with a respirator to filter out particles before you breath them, it would be best to not have this material type in a rock wool panel or any other such panel. The second reason is that these material types give poor acoustical performance when it comes to the rates and levels of absorption for music and voice.

Understanding the Inadequacy of Building Insulation for Acoustic Purposes

When you build or purchase a rock wool panel you must examine how the building insulation works. It works using air flow across its surface areas. When air moves across its surface area you can see the particles of this hazardous material type will become airborne. If they can ride on air currents they can get into your lungs. These particles once in your lungs are never removed by your body.

Some people will state that you can use this material type as a R value to keep your room warm or cool. Considering the installation requirements of a full body suit and a respirator, common sense tells us not to use this material type in any rock wool panel or inside our walls for a climate control. There are less hazardous material types such as wool that are more organic.

The Dangers of Airborne Particles from Rock Wool Panels

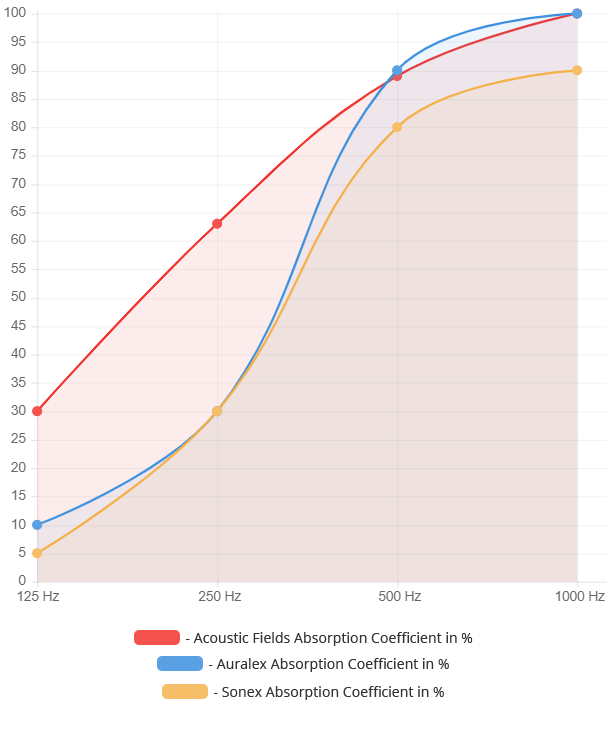

Rock wool panels also lack the proper rates and levels of absorption for music and voice. Music and voice require a linear rate and level of absorption. Rates of absorption must be smooth with no spatial irregularities in the absorption curves they represent. Building insulation was never designed as an acoustic tool. It was designed for climate control. People and companies have perverted its cheaper costs into a rock wool panel.

It was never conceived to be used for lower frequency absorption and it lacks the proper rates and levels of absorption for middle and higher frequencies. With the health hazards associated with this material type and the poor acoustical performance, it is best to stay away from rock wool panels and focus on technologies that were designed to treat both pressure and reflection issues within small rooms.

Why Rock Wool Panels Fall Short in Acoustic Performance

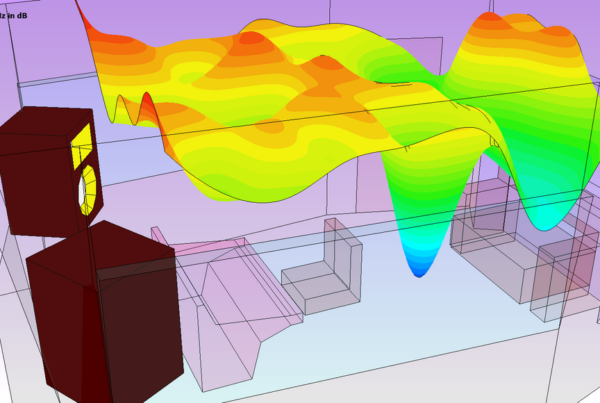

Room distortions come in two main forms. We have lower frequency pressure issues along with middle and high frequency reflections. Lower frequency pressure issues are termed room modes. Room modes occur when the length of the energy we are placing within the room does not fit into our room dimensions. When a 40 hz. wavelength at 28′ will not fit into our 13′ wide room, we will have a room mode. A mode excites the air between the sidewalls.

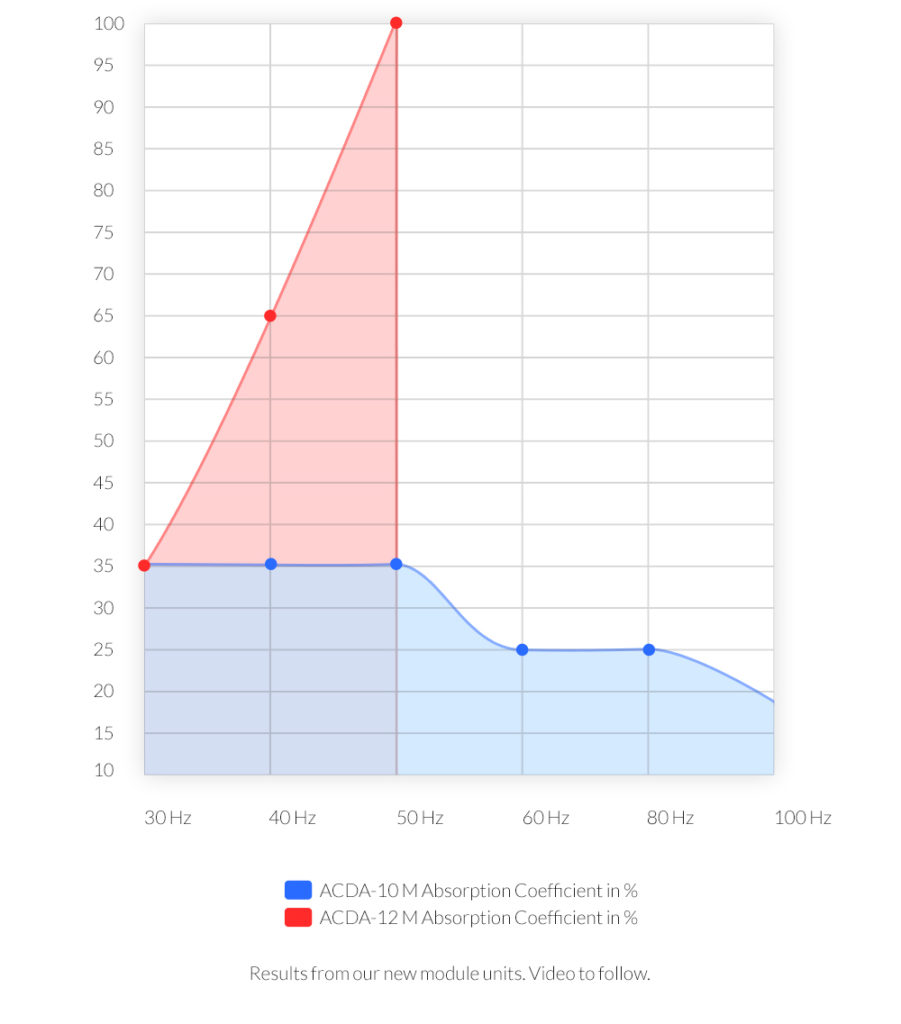

This air excitement exaggerates too much of certain frequencies and can completely eliminate other frequencies. We can have a “bass boom” or we can hear nothing at all depending on the dimensions of our rooms and the frequency and amplitude of the energy placed within it. To treat room modes, you need a specific technology such as our ACDA series and Carbon Panels.

Navigating Room Distortions: Pressure Issues and Reflections

Middle and high frequency energy is reflected from our walls, floors, and ceilings. These reflections confuse the other energy within the room by smothering it with time delayed energy that is distortion. The technical term for this reflection issue is called reverberation. Reverberation is defined as to how long a sound stays around within a room after it has been sung,spoken, or played.

Every surface area within our rooms contributes approximately 17% to the overall reverberation times. Reverberation is a measure of decay or how long it takes for a certain frequency amplitude to decay 60 dB from its original start. The treatment for reverberation is absorption technology that works well within the 125 hz. – 500 hz. frequency range. At Acoustic Fields, our CPA unit is designed for just this task.