What does the term mass loaded vinyl mean? It is obviously a vinyl material type but what does the mass loaded part mean? The word mass in mass loaded vinyl suggests that it has density or weight. Mass loaded vinyl has a density of 1 lb. for a 1/4″ thick piece that is 12″ x 12″. This mass in the term mass loaded vinyl is what gives the technology its performance. Mass loaded vinyl is denser than most vinyls and it is this density that makes it a good barrier material for middle and high frequencies. With a thickness of 1/4″, it can be used to minimize the transmission of noise from one structure to another. However, do not be fooled by claims that it will stop all noise. It will not do anything for low frequency “bass”. It can reduce noise transmission from voice but it will not keep your home theater quiet.

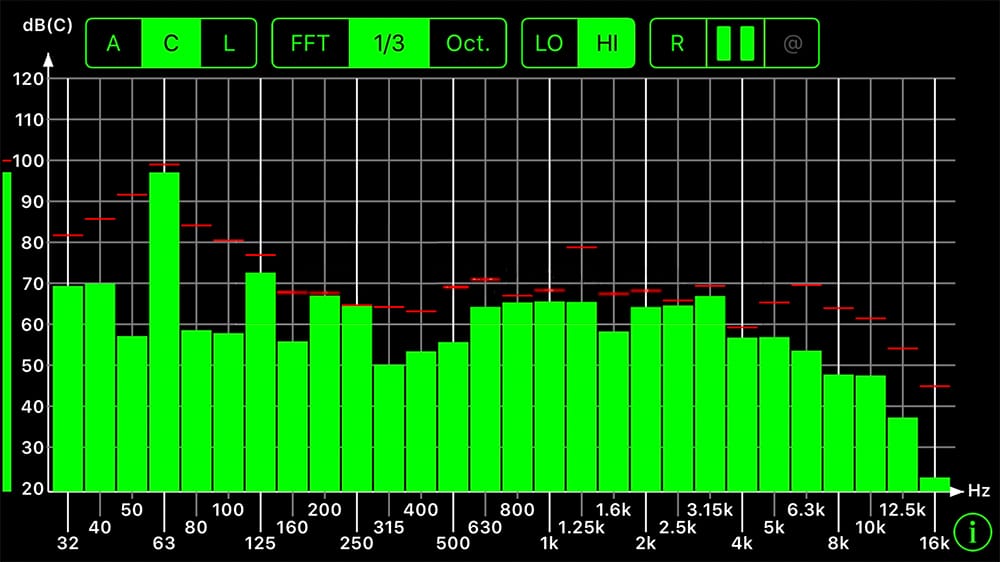

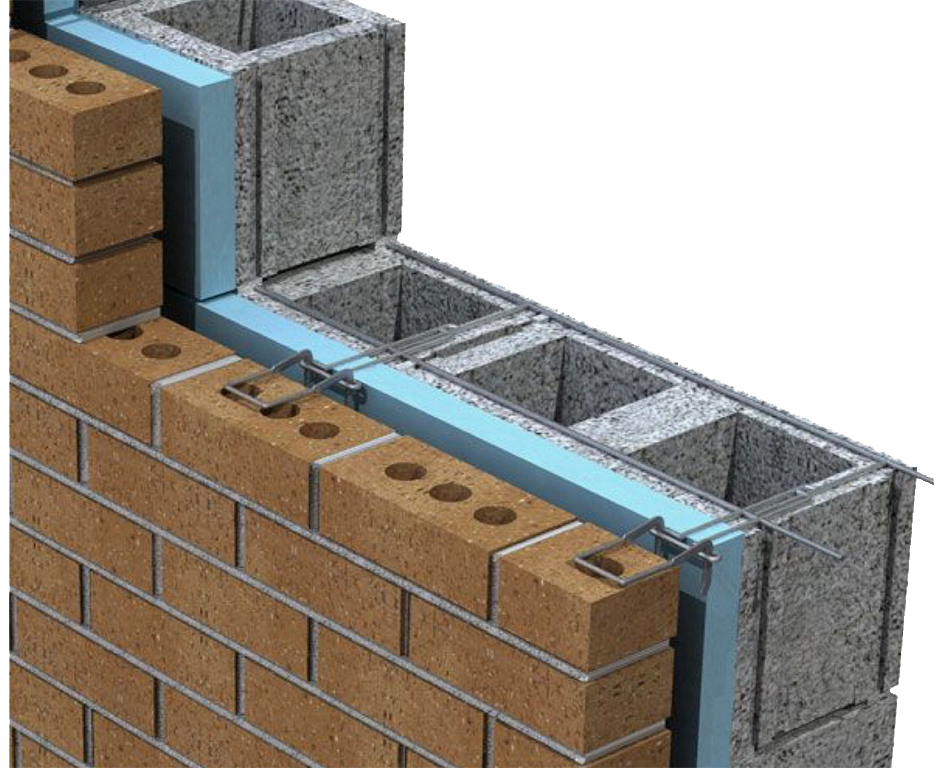

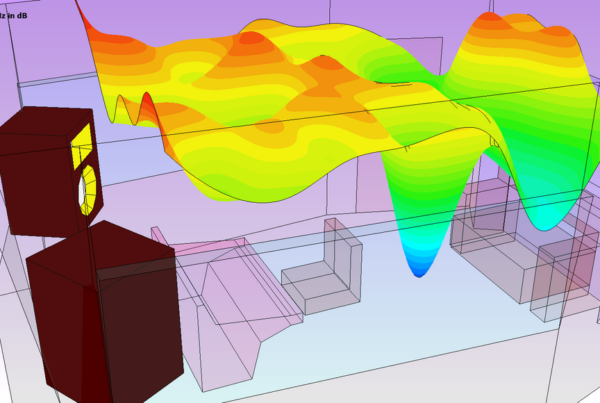

What is a barrier? https://en.wikipedia.org/wiki/Noise_barrier A barrier is what you build to stop or mitigate noise. It is a structure between you, the receiver of the noise, and the noise source itself. The barrier thickness and the materials you use to mitigate the noise transmission is dependent on the frequency and amplitude of the noise that is being transmitted. https://www.techopedia.com/definition/2025/noise Lets use people speaking in the next room. If you can hear people speaking in the next room, you will first want to measure the noise that is coming into your room. Every noise source has a certain frequency and amplitude. The frequency is defined in hertz and the strength of the noise at each frequency is termed the amplitude of the noise. In designing any barrier, we must focus on the frequency and the amplitude of all noise.

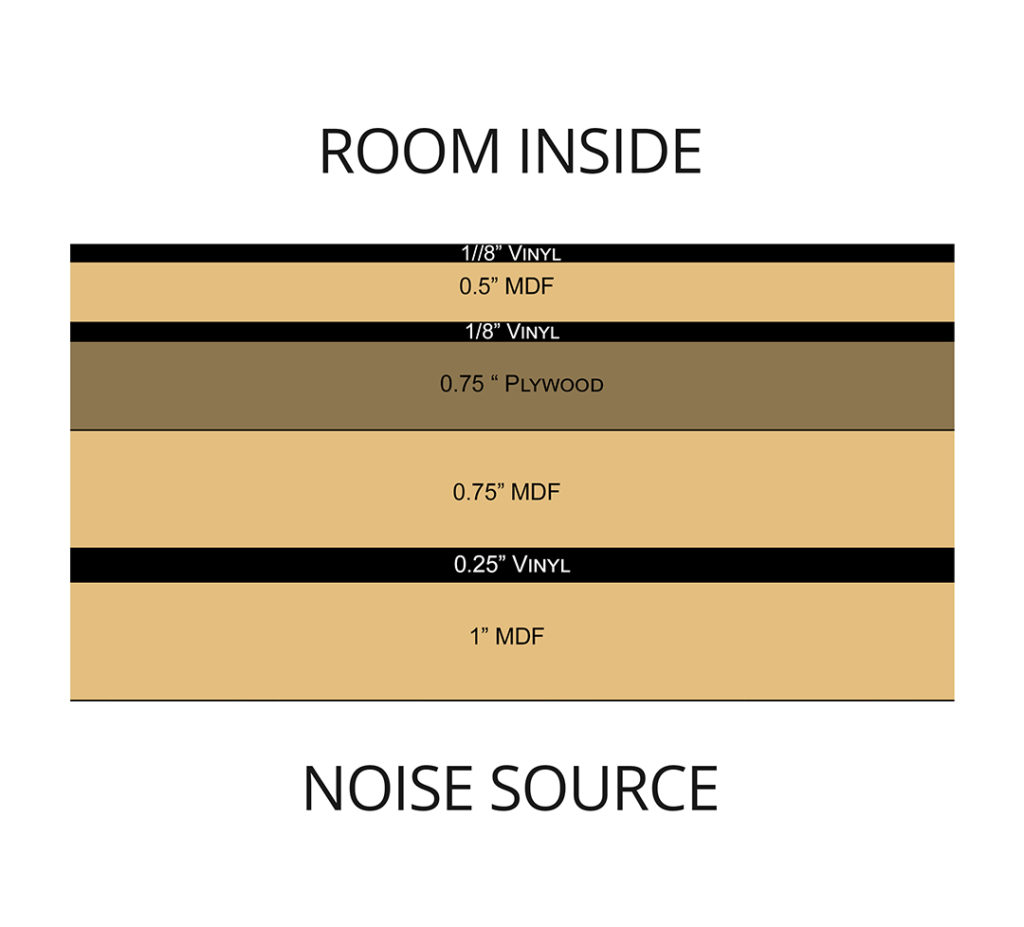

Every noise frequency range has a material type that is best at mitigating the transmission of that specific noise. Frequencies below 100 Hz. are termed low frequencies and are the most difficult to stop. Low-frequency energy from bass is long and tall waves of energy that go through everything, even concrete. Mass loaded vinyl will not be able to deal with low-frequency energy. It can be effective when it is placed within a “sandwich” or layering of materials to deal with lower frequency noise transmission issues. When designing a low frequency energy barrier and all other barrier types, we must first measure the frequency and amplitude of the noise. Once we have those noise numbers, we can then select the material types to use and just as importantly, how to arrange those material types together to deal with our specific noise issues.

How do we measure our noise issues? At Acoustic Fields, we have a process where we send you apps that you download on your phone. It is part of our noise and treatment design services https://www.acousticfields.com/sound-barrier-technology/. You then follow our instructions and take noise measurements using your phone and our apps. You take noise measurements twice a day over a seven day time period. You take a noise reading during the quietest part of the day and the noisest part of each day that you are going to be using the room. You record that data on our online form and send it to us. We then design the barrier you will need to build to mitigate your noise issues.All barriers are a permanent construction project. There are no wall hanging panels that you can hang to stop noise. Noise is like water, it will find the weakest link and go through it.

You can not guess with noise issues since the barrier types that you must build vary drastically in materials used, how many to use, and how to build them or arrange them in correctly to deal with your specific frequency and amplitude noise issues. Guessing what to build to stop your noise issues is both costly and time consuming. Most barriers that are built incorrectly, must be torn down and started again after noise measurements have been taken. With noise issues we must follow the old carpenter adage of measure twice and cut once. Noise must be quantified and qualified because with noise issues, we do not want to spend no more than one dollar more than we have to since a barrier is a permanent construction issue and we can not take it with us when we leave.

Hello Is MLV to be used under concrete siding and does it’s design valso substitute it for vapor barrier?

Thanks

What are the frequency and amplitudes of your noise issues.

Hello,I think MLV should be used beyond the concrete,do not need anthing to cover that ,but is not very efficient to reduce the sound, the effected method is to use polyester fiber acoustic cotton or fiberglass acoustic panel,these 2 materials can be used to under concrete.

Thinking a material type is the correct material type to be used without knowing the frequency and amplitude of the noise issue is a recipe for disaster. Every material type is frequency and amplitude dependent. MLV is a middle and high frequency barrier type.

You are right, I just consider for normal concern the client may not know about the frequency and amplitudes of the noise. Thank you for your professinal illustration.

Not our clients. We have processes that they can use to measure F/A. Guessing with noise is a waste of time and expensive. Most will guess wrong.