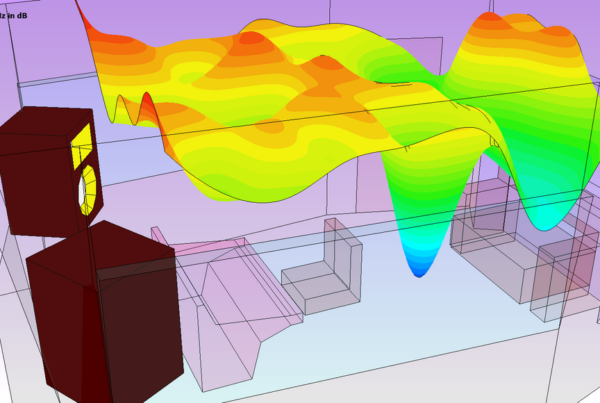

In today’s small home theaters, we have two main issues going on. First, we have a small room with large low-frequency acoustical issues. Room modes are everywhere. We can not get away from them. They are on the screen wall and both sidewalls. They are on the rear wall and most oscillate throughout our home theater rooms every 3′ – 4′ throughout the room. The floor to ceiling dimension is usually the smallest of the three and the smallest dimension in any room will produce the largest issues. The second issue we have is where to place the treatment requirements to successfully deal with axial, tangential, and oblique modes. If a wall surface area is producing the unwanted low-frequency pressure issues in our small home theater rooms we must usually treat the complete wall surface area. In small theater rooms this is usually not possible. Space is limited by smaller room dimensions and usually overcrowded with too many chairs and other furniture pieces. We need the treatment type but have limited space in order to treat those issues.

Large low-frequency issues require that we have large surface areas of coverage. Home theaters are all about car crashes and explosions. Special effects abound and the associated energy issues produce an issue that must be dealt with with the proper rate and level of absorption. What areas do we usually have to work with? We have the area behind the screen. Unfortunately, we have found that due to small room size most clients install the screen against the wall leaving no room for treatment behind it. If that is the case, we can go under the screen. Remember with low frequency issues it’s all about having enough square footage of the correct rate and level of absorption at the appropriate wall location. https://www.youtube.com/watch?v=tqSd26fiK8E Placing smaller units under the screen will provide us with some coverage on the dreaded front wall. The front wall is always the area with the largest low-frequency issues since it is the area where all the speakers and the subwoofer are located. These energy producing devices all excite the room modes at the theater room location. https://cmtext.indiana.edu/acoustics/chapter1_standing2.php

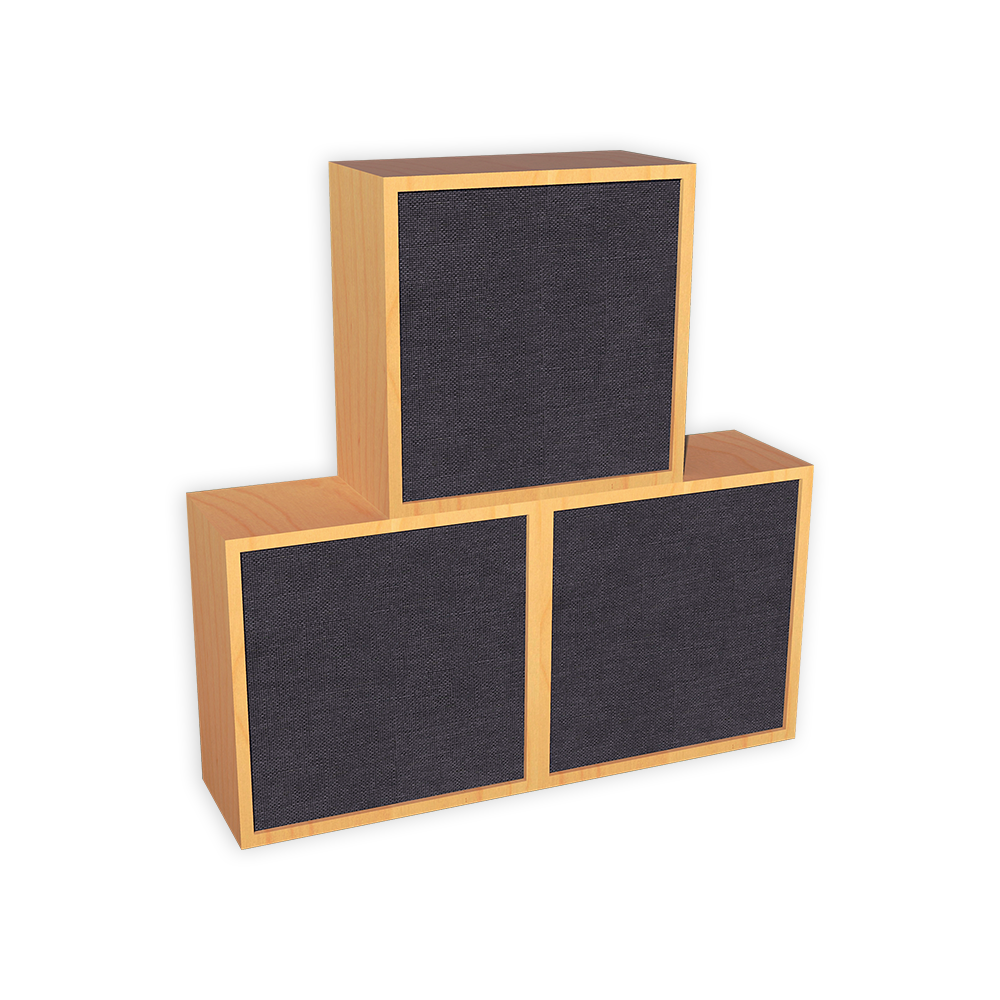

Sidewalls are usually smaller widths with seating taking up a lot of space on the sidewalls. We can place smaller module units around the seats. modules can be used to even act as a table where remotes and drinks can be placed. The rear walls suffer the same treatment requirements but lack the space for a 5 – 6′ unit which is what is really required to treat those specific surface areas. With a smaller module that can be custom built to fit or our standard module size which is 24″ x 24″ x 12″. With our modules one can stack them to create the necessary surface area coverage. We have even used our modules as a coffee table and as a seat platform to locate the correct rate and level of absorption close to the seating position. The best place to place low-frequency management technology is under the seats, to the right and left and even over the seated/listening position to handle that dreaded 60 Hz. issue with the 8′ ceilings we have to deal with in North America. http://artsites.ucsc.edu/ems/music/tech_background/TE-02/modes/Modes.html

Our module units are a smaller version of our ACDA-10 and ACDA-12 activated carbon broadband diaphragmatic absorbers. Our ACDA-12 unit is our highest performing unit with 35% absorption at 30 Hz., 63% absorption at 40 Hz. and an overwhelming 100% at 50 Hz. Our ACDA-10 unit is a broadband absorber that starts at 30 Hz. and goes upward through 6,300 Hz. With our foam on the face of each ACDA-10 module behind the face fabric we can reach all the way to 6,300 Hz. The frequency ranges from 40 Hz. – 6,300 Hz. is the frequency range that the engineers who mix our music and video work within. Units can be chosen with over 50 fabric colors and textures. Both the ACDA-12 and the ACDA-10 modules can be finished in a wood veneer or painted any color to match your existing home theater decorum. Most rooms will require a mixture of the ACDA-12 and ACDA-10 units. Rooms must be analyzed to determine the frequency issues due to the room dimensions of width, height, and length. Once the frequency of issue has been determined we then look to the amplitude or how strong those frequency issues are at that specific wall location.

ACDA-10 Modules: https://www.acousticfields.com/product/acda-10-m-modular-bass-absorber/

Fabric Options: https://www.guilfordofmaine.com/acoustic

If there is no space left to treat the low-frequency issues within our small home theater rooms, we can then look at the reflections from the floor, ceiling, and the four walls. Reflections from these surfaces contribute to what we call in physics reverberation times. Reverberation times are the summation of all the reflections from every wall surface area. Each wall surface area contributes around 17% to the total reverberation issues within small theater rooms. Reverberation is defined as how long a sound stays around within the room after it has been spoken or sung. people confuse reverberation with echo all the time. Echo is a repeating signal usually over distance. Reverberation is room distortion produced when too much energy “hangs” around within the room after its time has come and gone. To treat reverberation times we must use a middle and high frequency absorption technology. This can be done economically using an open celled acoustic foam technology. With reverberation time management it is all about surface area coverage as it is with low-frequency management technology. You must cover enough of each offending surface area to minimize the amplitude or strength of the reflection.

Not any type of absorption will work for proper reverberation time management. Music and voice that is produced within our small theater rooms is different than noise. Most companies’ products are designed to absorb noise. Their design goal is to absorb as much energy per square foot as you can with the product. Companies use building insulation to usually treat reverberation times. Building insulation over absorbs at middle and high frequencies which drains the life out of our music and voice. Absorption is an energy transformation from friction to heat. Once our music and voice is absorbed, it is lost forever, converted to heat. With our music and voice, you must use the proper rates and levels of absorption to absorb just enough of the excess room reflections that produce reverberation without destroying the music and voice by over absorbing. Our Studio Pro Foam was designed specifically for music and voice. at a cost of 2 M and 8 years in development it is the finset open celled foam ever produced for music and voice.

About Us At Acoustic Fields: https://www.acousticfields.com/about/