There is no such animal as foam panels for soundproofing. Foam panels do not stop sound. Foam panels absorb sound energy; they do not reduce the transmission of that noise from the source to the receiver. If there ever was a foam panel for soundproofing it would not “proof” anything. Assuming here that your definition of proofing is reducing the transmission of noise from one place to another, there can not be a foam panel for soundproofing. Foam is a sound absorption technology. It is used inside the room to manage reflections and some lower frequency excess pressure issues. It is not a full frequency range sound absorbing technology. It is limited in which frequencies it can absorb at and through. Foam technology is used mainly for voice and music rooms. It is designed to absorb excess reflections from wall surfaces that create high reverberation times. High reverb times muddy our vocals so we hear some parts of the voice but not others. With music it can smother certain frequency ranges where you will hear no music if that music lies within the impacted frequency range.

Soundproofing a room: https://www.popularmechanics.com/home/interior-projects/how-to/g2470/soundproofing-a-room/

Noise Measurements: https://www.acousticfields.com/sound-barrier-technology/

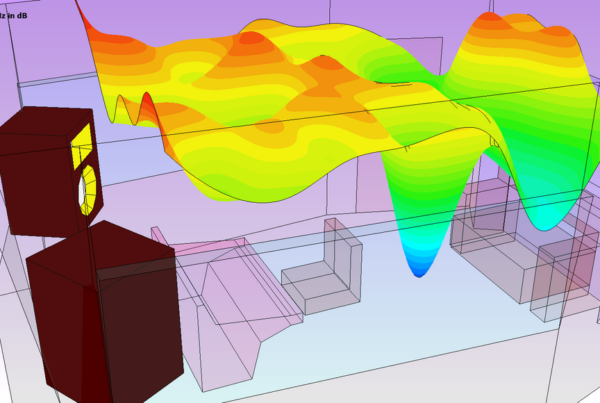

Soundproofing is a term that is associated with noise. Noise is any sound energy that emits from a source and is heard by a receiver which is usually a person. Noise can be caused by garbage trucks, foot traffic, people activity and a whole host of other sources. Each noise source produces sound that falls within a certain frequency range. Low-frequency energy is long and tall. Middle and high frequency energy is short and thin. In order to build the correct barrier type you must know what frequency and amplitude the noise it is at. The frequency tells you its signature. The amplitude tells you how strong it is. You must know what it is and how strong it is in order to build the correct barrier technology. Every barrier technology is dependent on materials and construction methodology upon the frequency and noise it is designed to stop or “proof”. A barrier is what you build between the source of the noise and the person or receiver who is bothered by the noise. All noise must be measured. It must be quantified and qualified. Without measurements you are guessing and guessing with noise is a fool’s game.

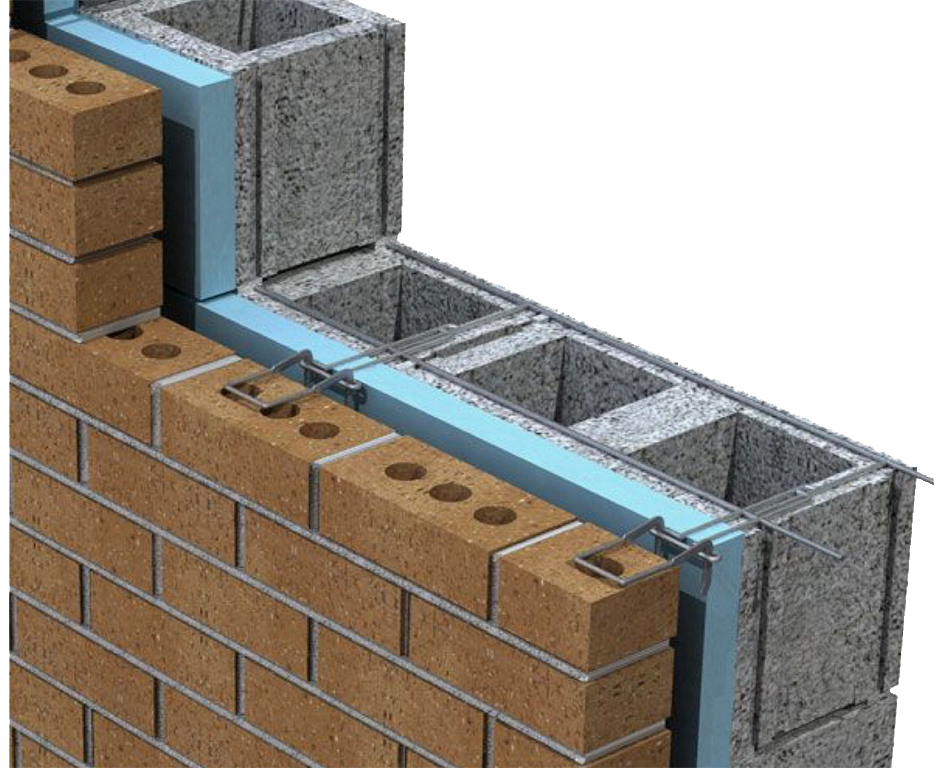

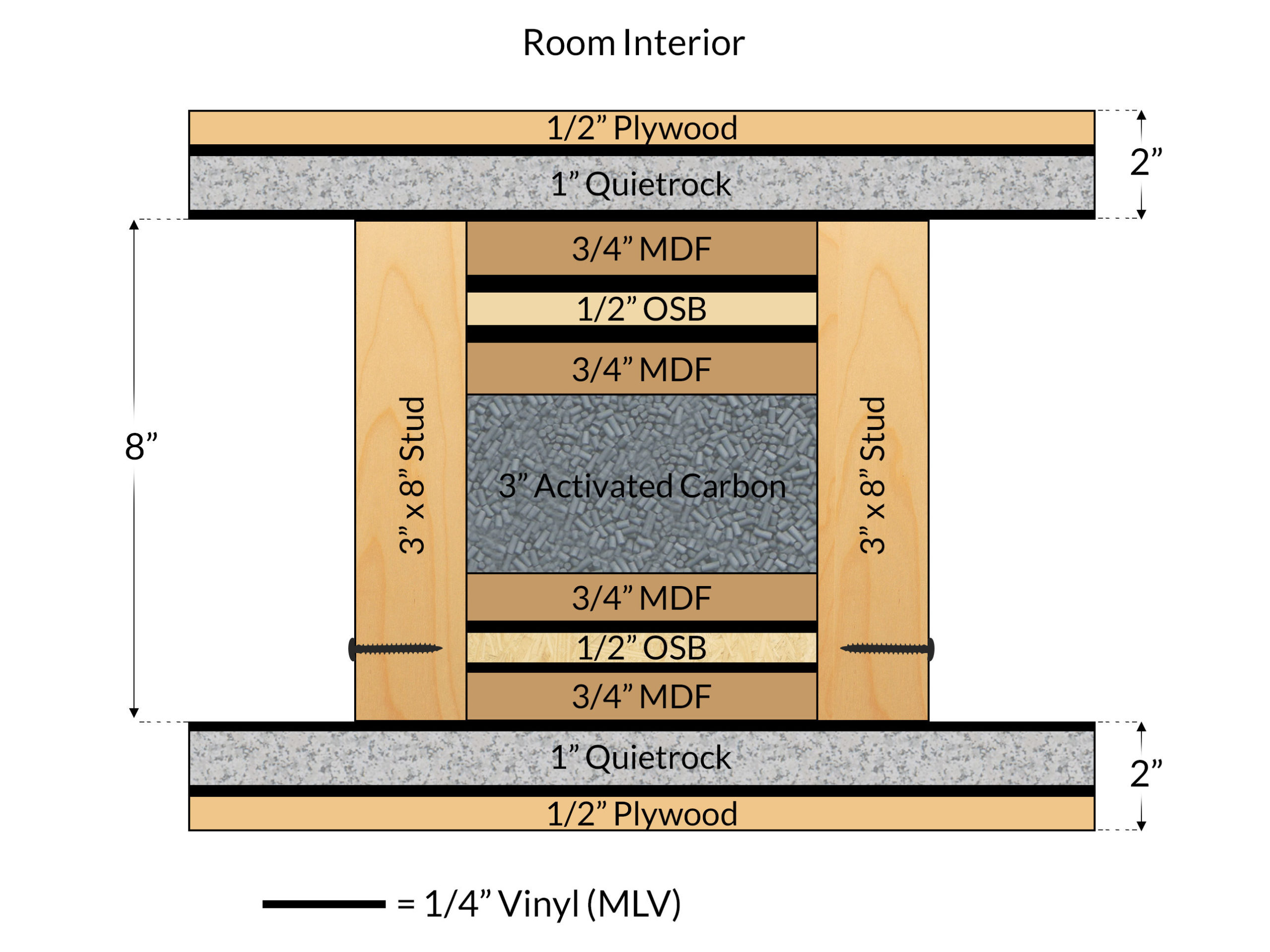

After we measure the noise, we must design the barrier. The barrier design is directly related to the frequency and amplitude issues the noise measurements indicated. The material types that you use in the barrier are arranged in a certain order. Sometimes the most dense material will be on the barrier side that faces the noise source. Sometimes it will not. The middle layers of our barrier “sandwich” are also based upon the frequency and amplitude or strength of the noise we are dealing with. Everything starts with the noise measurements. You must measure twice and build once. Barriers are expensive and almost always involve some type of construction process. Keeping the noise outside of your room where it belongs makes the room sound better already. Now, we must add the appropriate treatment type, amount, and position that technology correctly. This is where the term foam panels for soundproofing was used incorrectly. There are no foam panels for soundproofing. There are foam panels for sound absorption.

Open celled, acoustic foam is a cost effective and space saving technology to manage the excess middle and high frequency energy within our rooms. Foam can be manufactured in large sheets and cut to fit any size and shape configuration to match the room usage. If we are using foam inside a live room then we will need a certain amount based upon the room size and volume. If we are treating our home theater, we will need middle and high frequency absorption everywhere since we have multiple channels of energy spewing into the room from all directions. This energy amount then strikes the walls and reflects off of the wall surface areas. You take all four walls and then the floor and ceiling and turn each surface area into a giant speaker. When you add all of this reflected noise from all the walls, floor, and ceiling you get what we call in acoustics high reverberation times. Reverberation is the measure of how long in time that a sound stays around within the room after it has been spoken, played, or sung.

To manage all of this reflected energy we turn to acoustic foam. It can be used just as raw foam and tacked up to any wall surface. You can outline the foam with a wood frame and make it easier to hang on the wall. You can cover it with fabrics and choose any color or texture to match existing decor. Foam is versatile and can be cut into any shape or size to satisfy the usage design objectives. You can increase the foam thicknesses to achieve even lower levels of performance depending upon the strength or amplitudes created by the chosen room usage. Here is a link to a professional grade foam product that took 8 years to develop at a cost of 2 M. It is the finest quality ever created and exhibits the best rates and levels of absorption for middle range voice and music.

Studio Pro Foam: https://www.acousticfields.com/product/acoustic-foam/

Foam Sizes: https://www.acousticfields.com/acoustic-foam-overview/

About Us At Acoustic Fields: https://www.acousticfields.com/about/