There is no such thing as a foam bass trap. A low frequency absorber is not made from foam. There are three main types of low frequency absorption technologies that lie within our current laws of physics. We have diaphragmatic, membrane, and Helmholtz. There is no foam bass trap in this list. Foam is not a low frequency material type. Open celled foam is for middle and high frequencies. When you think of any foam absorption technology, you should think of the voice. Foam is for middle range voice frequencies. Lower frequency energy comes from your bass drivers in your speakers or the truck.

There can be no such thing as a foam bass trap since foam is not a lower frequency absorption material type. Wrong material type for the application. With a starting point of using the wrong material type, with the material type that can’t work, you have nothing more than marketing speak. You have a product that in its description is incorrect. There can be nothing about a foam bass trap because it can not and does not exist. Foam is for wall hanging panels to manage reflections.

The Most Powerful “Bass Trap” – Diaphragmatic

If low frequency management is our objective, we must use diaphragmatic absorption. There are also membranes and Helmholtz. Diaphragmatic is the most powerful per square foot of the three types. A diaphragmatic absorber is a cabinet with a certain depth. The depth of the cabinet determines the lowest frequency that the unit will work or absorb at. The internal cabinet fill material, our carbon , manages the rate or how much absorption occurs at each octave band.

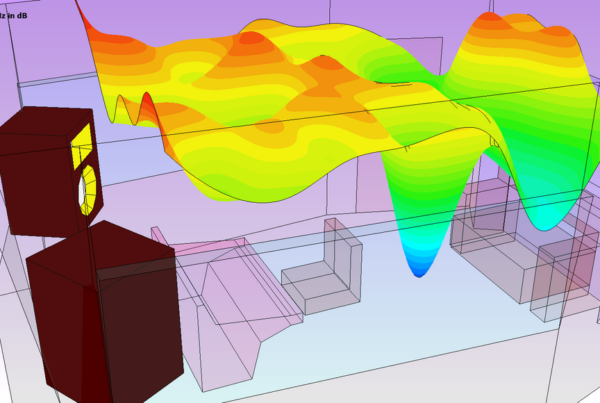

Room Pressure Waves

With low frequency pressure issues you must design for the highest rate so that every square foot of the unit is producing as much lower frequency absorption as possible. This performance requires that the cabinet has sufficient mass to create the cabinet density goals. At Acoustic Fields, our ACDA series also come with two front walls that face the inside of the room against the room pressure waves. The dual front wall pieces are of different densities to produce an inverted phase relationship with the pressure wave.

Carbon inside of a perforated absorber

Lower frequency sound absorbing technologies have weight and density. Mass is required with diaphragmatic absorption in order to meet cabinet density requirements. The cabinet density must be over 4 lb. / sq. ft.. The front wall densities must be different densities which will make them different thicknesses. The internal carbon fill material is suspended inside a perforated absorber. With our ACDA series we have a carbon perforated absorber inside a diaphragmatic absorber. This process allows us to absorb a large majority of the energy inside the cabinet.

Cutting of the head & tail of pressure waves

When we place over 50 lbs of our carbon inside the cabinet of the diaphragmatic absorber, we lower the atmospheric pressure inside the cabinet. The low frequency wave energy is created at normal atmospheric pressure. The internal cabinet pressure is lower in pressure than the outside the cabinet pressure. When the wave energy goes through the dual front walls it is slowed down in speed before it enters the cabinet with the internal cabinet perforated absorber. When the wave energy “sees” the reduced pressure inside the cabinet it collapses. We call it cutting off the head and tail of the wave.

Add foam to your “foam bass trap”

Low frequency energy that strikes the cabinet does three things. First, it can go right through the complete unit. Some of the lower frequency energy will be reflected back into the room. The rest will be absorbed using the diaphragmatic shell cabinet and internal perforated absorber fill assembly. The cabinet depth produces 30 hz. resonant frequency unit start frequency and the carbon perforated cabinet fill increases the rate of absorption above the 30 hz. start point.

When we add our foam technology behind the face fabric, we can extend the frequency response out to 6,300 hz. which is the frequency range that mix engineers work within. With our ACDA series, you have low, middle, and high frequency absorption in one product. A broadband absorber that covers a wide frequency range reduces the need for numerous unit types.

Reduce reverberation

Foam panels that are used for middle and high frequency absorption can be hung from ceilings to reduce reverberation time in restaurants. Reverberation is produced by reflections from the walls and ceiling of the restaurant. These reflections produce sound that stays around within the room too long. It stays around within the room after it has been sung, spoken, or played.

Reverberation also has a negative impact on speech intelligibility which is defined as how many words in a ten word sentence you can clearly hear. With high reverberation times, you will have difficulty in hearing the person next to you speak. High reverberation times with low Speech Intelligibility times are a common issue for churches.