The term DIY sound absorbing panels is a search term people use for building their own sound absorbing panel. The next issue that needs to be addressed is what frequencies are you trying to absorb with your DIY sound absorbing panels? Are you trying to absorb low frequency energy? How about the middle and high frequency energy? How about doing both low, middle and high frequencies all in one DIY sound absorbing panel.

In any design project you must know why and what. Why are you building and what are you building to satisfy the why. You must have a strategy. Using tactics and building any type of DIY sound absorbing panel may not achieve your objectives. Then, you must start over with a new design and a new build. Let’s get it right from the beginning by examining two main types of DIY sound absorbing panels. Let’s look at low frequency DIY sound absorbing panels.

The 3 types of sound absorbing panels

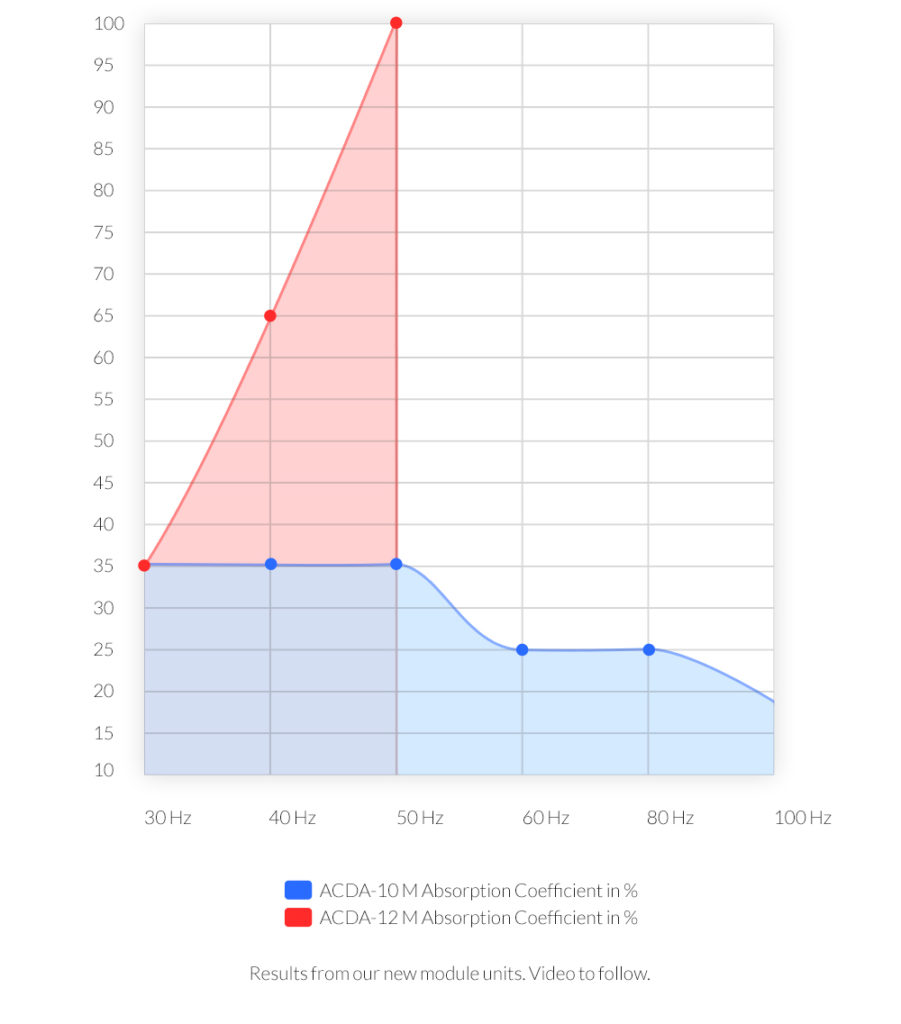

There are three types of low frequency DIY sound absorbing panels. There are diaphragmatic and its cousin membrane along with Helmholtz resonators. Diaphragmatic low frequency absorption is the most powerful of all three types. Membrane absorption panels have a similar frequency response to diaphragmatic absorption. However, due to their lighter cabinet density they do not absorb as much energy at each octave band than a diaphragmatic absorber.

A Helmholtz resonator works in narrow frequency bands and is limited in its ability to grab a lot of energy with a single unit. Multiple units are required due to their poor absorption coefficients. Diaphragmatic absorption is the best low frequency absorption for any DIY sound absorbing panels project. Our diaphragmatic absorption process pound for pound and foot per foot is the highest performer of anything in the market.

Use Activated Carbon In Your DIY Panels

Inside of our DIY sound absorbing panels at Acoustic Fields, we have our carbon technology. The carbon increases the rate of absorption. With diaphragmatic absorption, the cabinet depth produces the level of absorption or how low in frequency the unit will start working at. It is a combination of cabinet depth, the density of the cabinet and the internal material fill that all contribute to the performance of the unit.

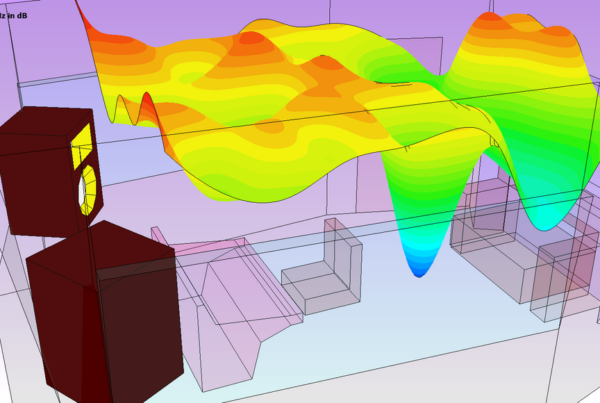

Our carbon diaphragmatic absorber is the most powerful of all low frequency absorption technology. These are pressure activated units that must be placed along each wall. Since low frequency pressure issues are throughout the room, you will need to cover enough surface area along each wall surface area with DIY sound absorbing panels in order to reduce the unwanted pressure along each wall surface area.

Read more about us here: https://www.acousticfields.com/about/

StudioPro Foam by Acoustic Fields

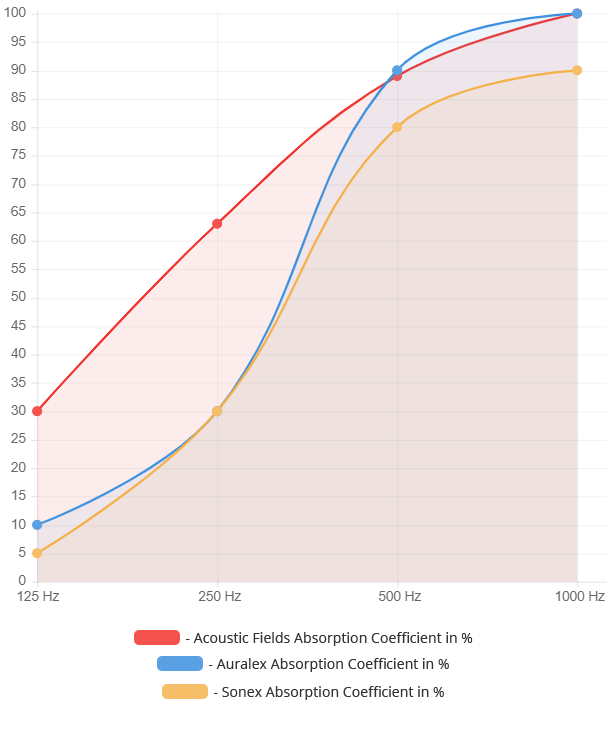

Another issue small rooms face are the reflections from wall surfaces. Reflections must be managed through sound absorption or sound diffusion. Both of these treatment options are available in a DIY form from us. Our proprietary foam technology is available for building using our DIY build plans. With our foam technology, we send you our foam and you build the DIY sound absorbing panels using our build drawings.

Sound absorbing foam for your DIY project

Our foam technology has the smoothest rate and level of absorption for middle and high frequency reflections. Look at the graph below. Notice the smooth rate of absorption from

125 hz. – 500 hz. This is the most critical frequency range for human voice. Having a technology that does not have any peaks or dips in the performance curve. Notice the spatial irregularities in the competition performance. You cannot treat an issue with a technology that is not smooth and consistent in its performance curves.

In small rooms, we have two main issues. We have lower frequency pressure issues and middle and high frequency reflections. Both must be managed if you are to eliminate acoustic distortions. Room distortions can be managed using a DIY approach that offers build plans which will show you how to build the technology into your DIY sound absorbing panels.

Take advantage of our FREE room analysis service

With any room treatment type, you must cover enough square footage of each wall surface area to deal with the frequency and amplitude of the issues at each wall location. Every wall location has a different issue and you must match the treatment type to the problems your room usage and dimensions produce. We can assist you with this process. Fill out the information in this link and schedule a call time slot to speak with Dennis.