Today we’re going to talk about diaphragmatic absorption.

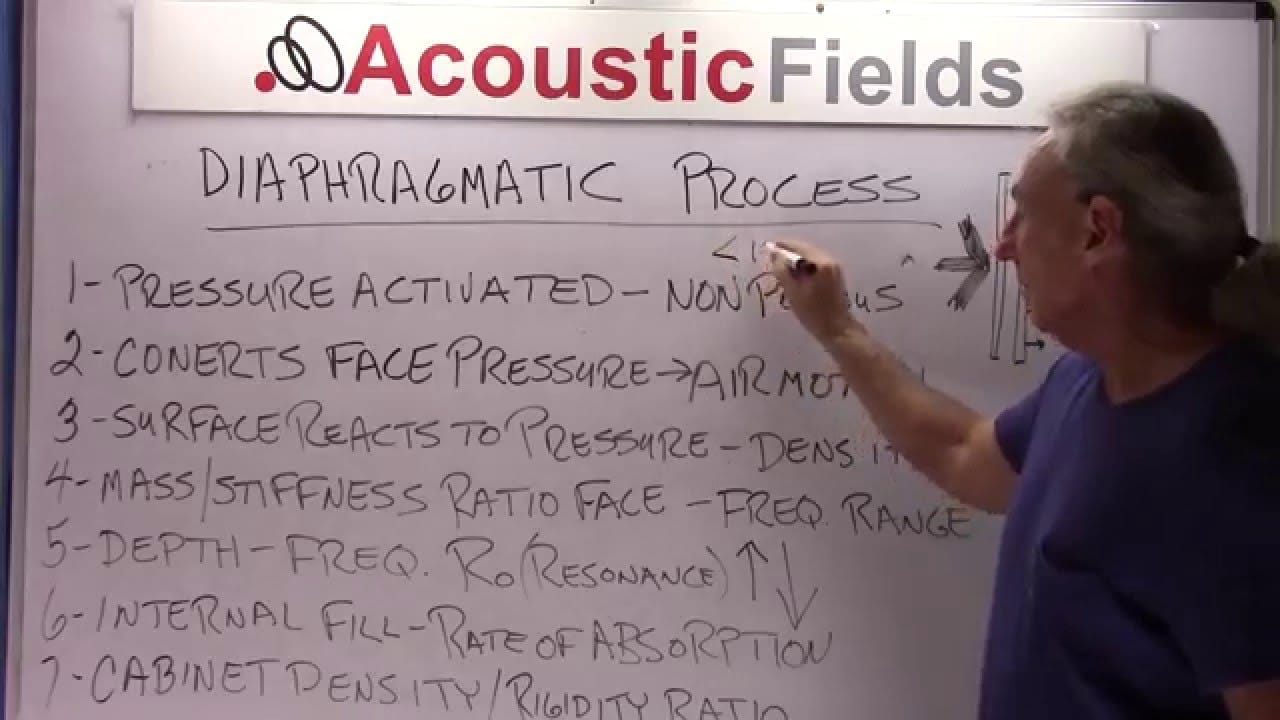

The process that is involved is the process we that use in our low frequency absorption technology. The process has been around for years, we did not create it, we did not invent diaphragmatic absorption. It is used extensively and studios build it a lot of times not accurately but it is used. I’s basically a sealed chamber, a wall, a two-by-four, two-by-six, two-by-eight interior wall sealed with dry wall on both sides. You can actually calculate the resident frequency, and find that for that particular material type and cavity depth and all that can be calculated. So what is diaphragmatic absorption? It’s a pressure activated device. There’s no holes in it, air doesn’t move through it. Indirectly it does, but we’re going to walk through the process, so it’s a sealed unit that reacts on pressure.

So what is pressure?

What we know from past videos is, that pressure is any frequency less than a hundred cycles. So it’s really a low frequency technology if it has enough horsepower like our does obviously you can make it broadband. We take diaphragmatic absorption, we had our phone technology to the face, so with our diaphragmatic absorbers you can get coverage from thirty up to 6300 cycles, so that’s very broad band if you need it. So lots of flexibility there to help you with tuning your room.

How does it work?

It converts pressure from low-frequency energy below 100 cycles in this example, and it strikes the front wall. In our diaphragmatic absorbers we have two walls. Most have one, but we have two that are out of phase with each other. This back and forth out of phase movement slows this huge pressure wave down. This back and forth movement of these dual walls forces air movement into the cavity. Into the cavity we find our carbon. And what the carbon does is it controls the rate of absorption. The level of absorption is determined by the front wall density stiffness ration and construction, the depth of the cavity and then the density of the cavity, or density of the cabinet itself.

In our units we use a dual rear wall, this sandwich between a layer of damping compound. So we have an extremely rigid rear wall and then this layout that you see here. So the surface reacts to pressure, the pressure starts air movement on the inside of the cabinet, which is filled with carbon. Carbon is very absorbent. So in a way – I’m just using this for purposes of illustration – it’s almost like a vacuum inside this thing. So a big pressure wave out here moves through this low pressure area and that’s how you get this huge amount of absorption. So there’s a ratio you have to follow with the mass and the stiffness of the front wall.

There’s a ratio you have to follow in the stiffness and density of the cabinet, and then the depth of the cabinet, like we discussed, will get you your resident frequency. All frequencies below the resident frequency will not be absorbed. All frequencies above the resident frequencies will be. So you have a lot of design variables that you have to calculate. And the internal fill material gives you the rate how much and what frequency and how fast it absorbs in what amount of space. And that’s the goal to get the most absorption in the smallest amount of space. And then the cabinet density has to have a certain density and a certain stiffness ratio to make all these variables work together. So that’s the diaphragmatic process, pressure activated, air movement on the inside, proper cabinet construction, and you can get a lot of absorption in a small amount of space if you use the right internal cabinet fill.

—

This is an unedited transcript from our video series from Acoustic Fields. There will be some errors in grammar and sentence structure that occur during this translation process.

For complete understanding and comprehension, please view the video which is included in this text. For any additional information regarding this topic or others relating to room acoustics, please contact us directly at:

P: 520 – 392 – 9486

The discussion on ductwork noise transmission from Acoustic Fields highlights crucial aspects of HVAC system acoustics. The movement of air…

Great build plans. thank you Denis

You must use absorption. Never place a chair against a wall.

A friend and I built several diffusors using these plans and they turned out absolutely beautiful. Very good instructions and…