Decorative acoustic panels usually place appearance over function. Looking pretty is more important than doing the job they are required to do. It’s a similar paradigm in current society. Form plus function equals essence. There are plenty of decorative acoustic panels out in the marketplace. They have a form, but no real function when it comes to treating the issues faced in today’s critical listening rooms. Music and voice require certain rates and levels of absorption technology. Decorative acoustic panels are focused on the middle and higher frequency ranges. They are usually hung upon a wall surface area to minimize the impact of reflections which contribute to the overall reverberation times within the room. Most are fabric covered and 2-4″ in depth. The cabinet depth determines how low of a frequency they start working at. Let’s examine how middle and high frequency sound absorbing panels work in order to understand form and function.

https://en.wikipedia.org/wiki/Acoustic_panel

Decorative acoustic panels work using air flow. Air must flow across the surface of the decorative acoustic panel. The air movement is termed molecular velocity. Air moves across the surface of the chosen sound absorbing material type creating friction. We all know that friction produces heat. When you process through air movement into friction/heat, you produce an energy change or transformation. Energy is not destroyed. It is changed from molecular velocity to heat using friction. Once the heat occurs, there will be sound absorption if the material type is selected properly to allow for this process to occur. The depth of the material type selected will determine the lowest frequency the panel will work at.

https://encyclopedia2.thefreedictionary.com/molecular+velocity

Not all rates and levels of absorption are created equal. Music and voice require certain rates and levels of absorption to manage the reflections from our room boundary surfaces. Building insulation which is one material type often used for decorative acoustic panels. It lacks the proper rates and levels of absorption to properly treat music and voice issues. Building insulation was never designed as an acoustical tool. It was designed for BTU retention and for maintaining warmer temperatures inside in the winter and cooler temperatures in the summer. Panels with building insulation will make the room sound too dead. Music and voice require a much more linear rate and level of absorption for their treatment in critical listening environments.

https://www.merriam-webster.com/dictionary/British%20thermal%20unit

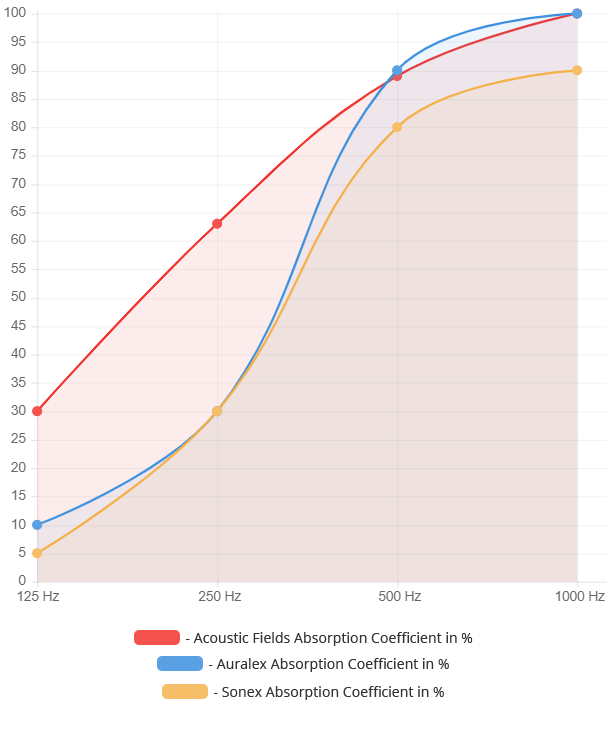

The most critical frequencies for music and voice begin at 125 hz. and go through 500 hz. This frequency range must be treated with linearity respect. The rate of absorption from octave band to octave band must be smooth with no dips or peaks. How can you treat an issue that has peaks and dips in response with a technology that has its own set of distortions. You end up treating distortions with distortions. The frequency ranges from 125 hz. – 500 hz. must be smooth and linear to assist the room issues you are trying to treat. predictability and consistency in performance must be the design parameters of any quality treatment type. Look at the graph below showing the performance of Acoustic Fields’ proprietary foam technology. Notice the red line at the top of the chart. Notice how smooth the rate is across the frequency range. This curve took 8 years and 2 M to create.

https://www.acousticfields.com/product/acoustic-foam/

When using any treatment type, we must allow for the proper amount of air flow across the chosen sound absorption technology. The goal is to allow as much air flow or molecular velocity across the surface areas of the panel. Any fabric will restrict that required air flow which will reduce the panel’s performance. If you then cover that fabric with ink or paint coloration, you reduce the airflow even more and thus performance suffers. You must use a fabric that has the proper air permeability rating. This rating tells you how much of the airflow is restricted by the weave and composition of the fabric. With a more restricted air flow, you will need more panels to make up for the decreased performance of each panel’s surface area.