Today we’re going to talk about why all sound absorbing foam is not not created equal. You see a lot of acoustic foams on the market place, you see a lot of different foams developed by acoustic manufactures. Foam is a relatively cheap, economical way to achieve absorption. Of course there are other methods out there but in terms if ease of use and installation and positioning and manufacturing and cost it’s a pretty economical absorption technology to look at.

But let’s look today at why all sound absorbing foam is not created equal, because they’re not and you’ll get a handle I think on one or two of the major differences here.

Open Cell Sound Absorbing Foam

We have two kinds of foams that you’re all familiar with, open-cell versus closed-cell.

Open cell foam is what we use in acoustics, it allows for air movement through the cell structure of the foam.

Closed-cell, we’re all familiar with too. These are the cushions in your couch, your car seats, etc. It’s a more dense foam that’s not really designed for middle and high frequency absorption, although we have done some tests with it for low-frequency absorption and it has some possibilities.

So open versus closed-cell. Those are the two main kinds of foam that you’ll see. Obviously open-cells is what we use for acoustics and sound absorption because it allows for the air movement to go through the structure of the foam, cause friction which causes heat and then we have an energy change so thus we have absorption occurring.

So what’s important here with open-celled foam?

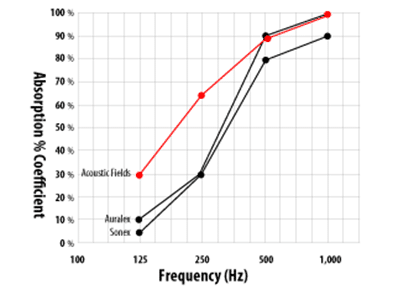

Two areas, the cell structure and the cell density. How many cells per square inch do we have and what is their structure? The more uniform the structure the smoother the absorption curve, the more uniform the density the smoother the absorption curve and this is why we went after this particular area because we were never happy with the absorption curves of the foams that were in the marketplace back when we did our research and development and, even today it holds true although they are getting a little better.

This video explains the back story on that point a little bit better.

So cell structure and cell density are critical to achieving some kind of smooth performance. Its smooth performance is what we want from our sound absorbing devices. We don’t necessarily want to absorb a hundred percent of everything, convert it all to heat and cause a hundred percent absorption because we want to have some of the energy to work with.

Management is key

Managing is the key. Reducing to a certain point and then adding diffusion to spread that cleaner, if you will, less reverberant signal out into the room.

So cell structure and cell density, what are the areas that we need to focus on?

Break point is 500 Hz.

Well the break point for acoustic foams is five hundred cycles. From five hundred cycles on up, with the two inch foam, it’s really easy to achieve a hundred percent absorption. That’s no real great feat in terms of design, however it’s the less than five hundred cycles that’s really critical because that’s where the male and female vocal ranges really come alive. That one twenty five, two hundred to eight hundred range for vocals, three hundred to eight hundred is really where vocals come alive for both males and females, so you have to be very careful with that particular frequency response range.

So we look at it as a more gradual kind of situation. Not a hundred percent absorption and working out. Just a little bit of a more gradual approach to the absorption. So it’s really below 500 cycles that a foam needs to concentrate on its performance rates and levels. That’s where our vocals are the most critical and that’s why all sound absorbing foam is not created equal.

In Summary

If you want to learn more about room acoustics and the problems you are facing in your room, then please sign up for our free room acoustic treatment videos and ebook which provide step by step instructions on all major room acoustic issues. Get instant access by signing up now.

Thanks

Dennis

Hi

Im lowering a ceiling to attempt to stop noise from above

Im looking for advice on which foam would be best to stick to the back of my board(shield) to try to absorb some of the noise whilst stopping it as much as possible

Im using a three layer shield with as much density as possible

but im looking to add a foam to help

can you advise please

Robert

R, Foam is not a barrier to noise. It is a sound absorption technology. Using a “three-layer shield” without knowing what frequency or how much of that frequency you are trying to reduce the transmission of is guessing. Guessing with noise issues is futile.