Speaker Vibration Dampener

Speaker vibration dampener can take many forms. A speaker is a small room. It has all the acoustical issues of a small room that we listen to music in, mix professional in or whatever critical listening environment we find ourselves. A speaker has a mechanical driver that moves back and forth to create frequencies of energy. The driver itself is moving and producing back wave energy inside the cabinet from the moving driver. This excess energy will not fit into the speaker cabinet and will create modal distortions in sympathy with the dimensions of the speaker cabinet. The cabinet itself will then start moving. Now, we have the mechanical movement of the driver, we have the internal speaker resonances, and finally the cabinet vibrations to contend with. Let’s examine each one of these to see the part they play in the speaker vibration dampener process.

Driver Basket

The mechanical driver must be designed well. I have seen some drivers who baskets move as much as the driver themselves. make sure you are using a driver that is surrounded with the proper physical support system to allow the driver to do its job without trying to compensate for basket vibrations. This will produce phase issues within the driver’s output and the spatial irregularities in speaker response. Irregularities in speaker response produce more room distortions. One step builds on the previous step. This building of distortion steps produces a synergy of energy that can reach audibility. Stay with a manufacturer that designs speakers that are to be used or modifies in other manufacturer’s designs. They have placed the design process ahead of all else when it comes to audio reproduction. Companies such as Dynaudio.

Dynaudio: https://www.dynaudio.com/

Speaker Cabinet

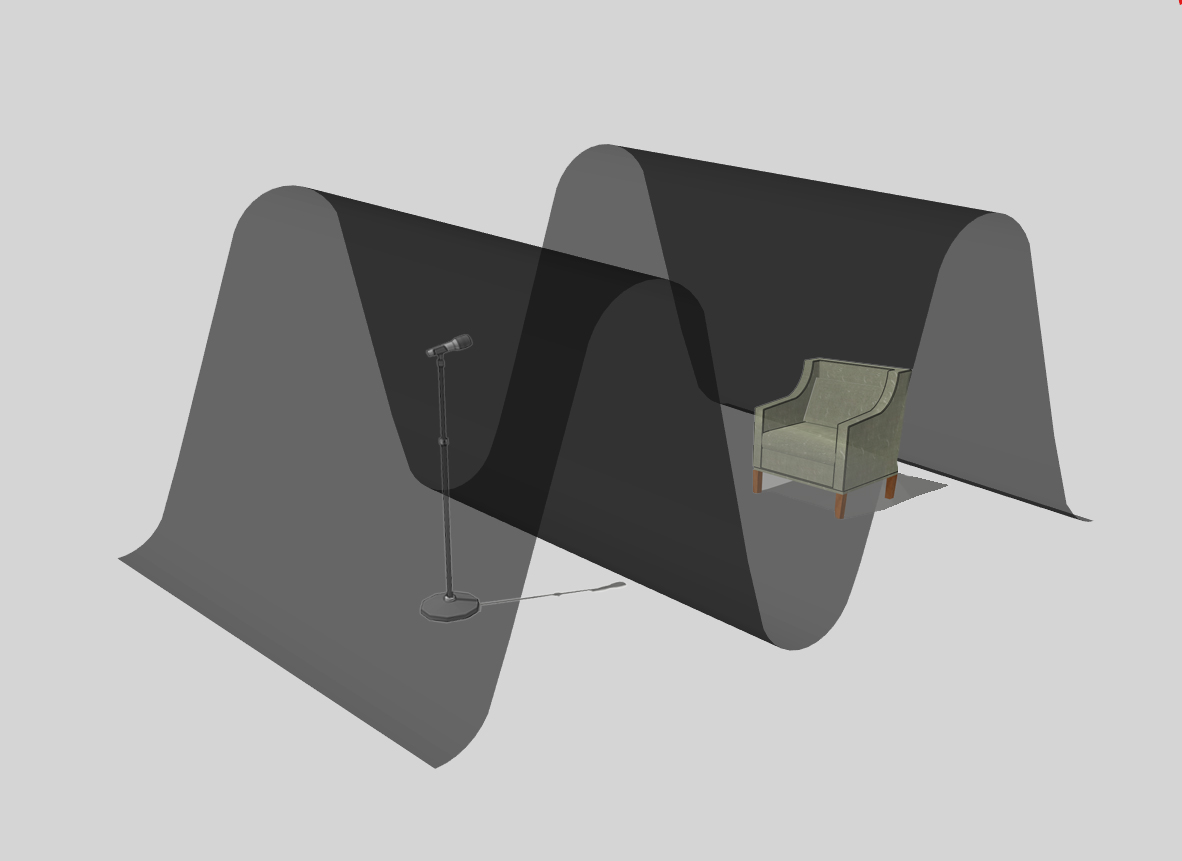

The goal with any speaker cabinets is to reduce structural vibrations within the cabinet itself. With the driver moving and the cabinets moving, there is too much moving going on. Movement and motion produce vibrations that are transmitted to the driver. The driver transmits vibration to the speaker cabinet and the speaker cabinet spreads its vibrational stink on to the driver. It is a dance of distortion when the opposite is the design goal. Two issues to consider. First, increase the mass of the cabinet by using materials that minimize vibrations. Use a multi-layered approach that has mass loaded vinyl in between each layer of material. Place your most dense layer on the outside of the cabinet. Place the thinnest layer inside the cabinet. Increase layer thicknesses as you move to the densest outer layer. This process will go a long way as a speaker vibration dampener.

Internal Bracing

The speaker cabinet will move back and forth with energy placed within the cabinet by the driver’s movement. The sides, top, and bottom will flex out with increased driver back wave pressure. To minimize this cabinet flexing, you can install cross bracing behind the driver magnet. You can brace diagonally from side to side, top to bottom, and any other direction your accelerometers tell you. Make sure that you isolate the brace to speaker wall contact points with a mass loaded vinyl layer between the brace and the cabinet itself. Cross bracing added to the multilayered cabinet is a good start. Now, let’s look inside our very small room which is our speaker cabinet.

Cabinet Resonances

The inside of our speaker cabinet is the same area within our rooms. Both the speaker cabinet and the room have a width, height, and length. They both have volume. The goal with both is to manage the excess energy that speakers place within them. This process is accomplished by providing the correct technology that has the proper rates and levels of absorption to deal with the internal cabinet resonances. All resonances inside our rooms have a frequency and amplitude and also a location within the speaker cabinet and room dimensions. There is a resonant frequency of a room and a speaker cabinet. We must reduce the energy below and above the resonant frequency of each “cabinet”.

Treatment Types

There are many treatment types that people use for amplitude reduction of room and speaker cabinet modal issues. Some use building insulation stuffed inside the room or cabinet. Some use open-celled foam across the walls of the rooms and cabinets. These technologies are not a full range in their rates and levels of absorption. In a small critical listening audio room, we must be able to absorb energy down to 30 Hz. In a speaker cabinet the resonate frequency is larger so we may start at 60 – 70 Hz. inside our speaker cabinets. You must match the level of absorption the resonant frequency dictates and you must capture energy at a linear rate after achieving the proper level.

Activated Carbon

We have used our activated carbon technology successfully in treating rooms over the last 12 years. It is now available for use inside your DIY speaker designs. Our activated carbon can now be installed inside your speaker cabinets to provide the rates and levels of absorption that the speaker cabinet requires based upon the driver size and the dimensions of the speaker cabinet. Our carbon technology can be installed on the inside walls of your speaker cabinet. We can control the level of absorption by increasing the carbon filter thickness. If you have an interest in pursuing a project of this type, contact us at info@acousticfields.com

About Us At Acoustic Fields: https://www.acousticfields.com/about/

I have three idential audio bookshelf speakers that sit horizontally on top of a dining room buffet converted to serve as a stereo cabinet. Inside the cabinet is an AV receiver. I want to minimize vibration of the speakers so I want to put some anti-vibration resonance material under each speaker, and perhaps under the AV receiver too.

I am considering using small sorbothane pads (probably 1″ in diameter and .5″ thick). I would put 4 under the corners of each of the three bookshelf speakers.

I am also considering cutting off a chunk of mass loaded vinyl to place under each speaker. I know MLV is used for soundproofing, but am not sure it will mitigate the speaker vibration.

What are your thoughts, please. Which should I use? Should I use both?

Thank you.

Try both and report back to us the results.