The issue with using a material that was designed for one particular function and then trying to make it fit into another category usage, and one in which it was never designed to do is that you never obtain the design goal which is as they say “soundproofing”. There is no such thing as soundproofing. Nothing is proofed. There are no absolutes when it comes to noise transmission. A blanket and using it to soundproof with blankets is not ever going to be able to stop or “proof” lower, middle, or some even higher frequency sound energy. Low-frequency energy below 100 Hz. will never be stopped by any blanket. A blanket will not even do well with voice which involves middle and high frequencies. There is no such thing as soundproof with blankets. Stopping noise or proofing is a complicated process. It involves many steps of which you must perform everyone and perform each step in the proper order.

Soundproof blankets: https://www.steelguardsafety.com/industrial-noise-control/sound-absorbing-blankets-industrial-sound-blankets/

STC: https://en.wikipedia.org/wiki/Sound_transmission_class

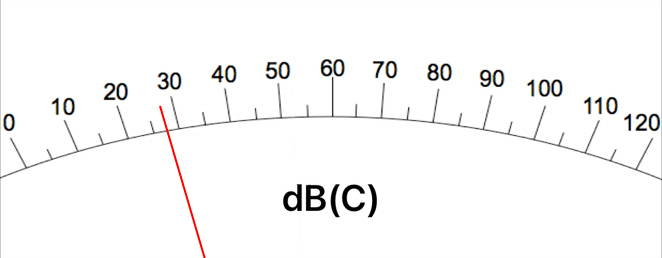

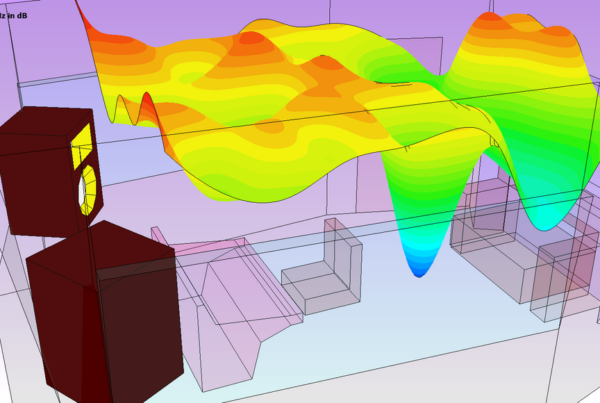

The first step you must perform is to measure the frequency and amplitude of all noise. Once you have measured the noise over a seven day time period you must then design the “blanket” you will use to deal with the specific frequencies of your music and voice. It will not be part of any soundproof with blankets operation. It will be a measured noise level with a proper barrier design that matches the frequency and amplitudes that were measured. Once you have the design you can build the proper structure that will stop all the noise you are up against because you have taken the time to identify the frequencies and amplitudes of each noise part. Blankets can represent a treatment type that works over a narrow frequency response range. A blanket will also have a lower STC or sound transmission rating.

If our goal is to reduce the noise transmission from frequencies above 100 Hz.then we must incorporate additional barrier technology than a blanket. Lower frequency energy will require a thicker material type and in most cases be a new construction project. Blankets are termed a limp mass material type. They are limp instead of rigid. A rigid type structure will be better for the noise attenuation of lower frequency noise. A limp mass material type is limited in the frequency range that it works within. People think that just because a material type absorbs sound energy it will absorb all energy types. That is not correct. Material types are limited as to what frequency and amplitudes of material types they can absorb at. This is due to their material type and construction methodology. A limp mass material will be better for middle and high frequency noise attenuation issues but it would never be able to absorb lower frequency energy that is 30 – 40′ long.

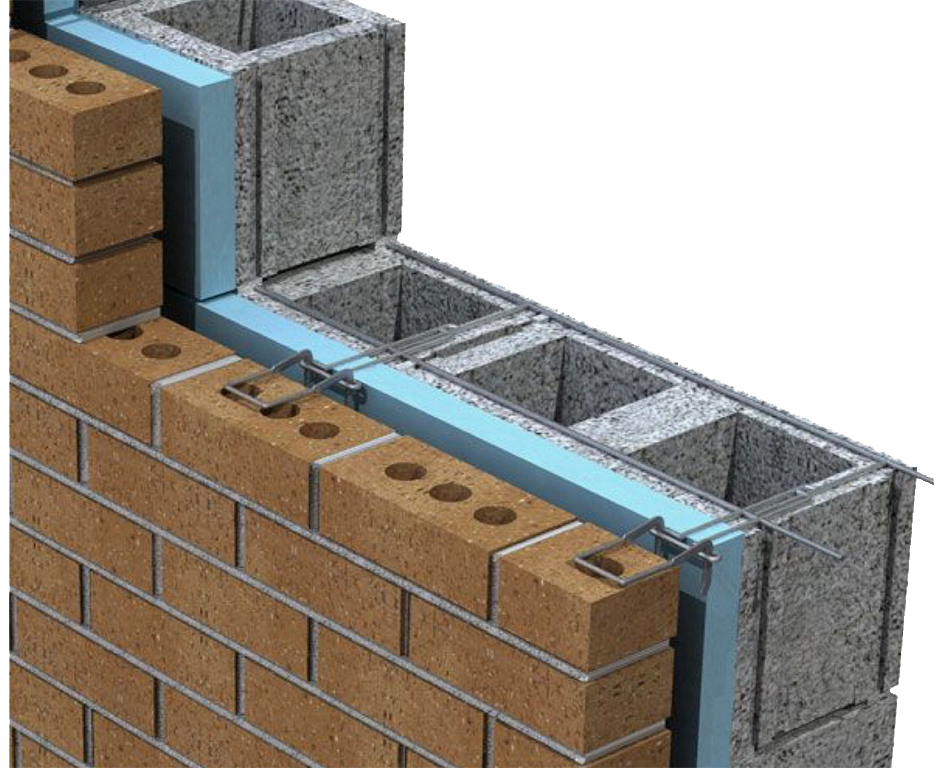

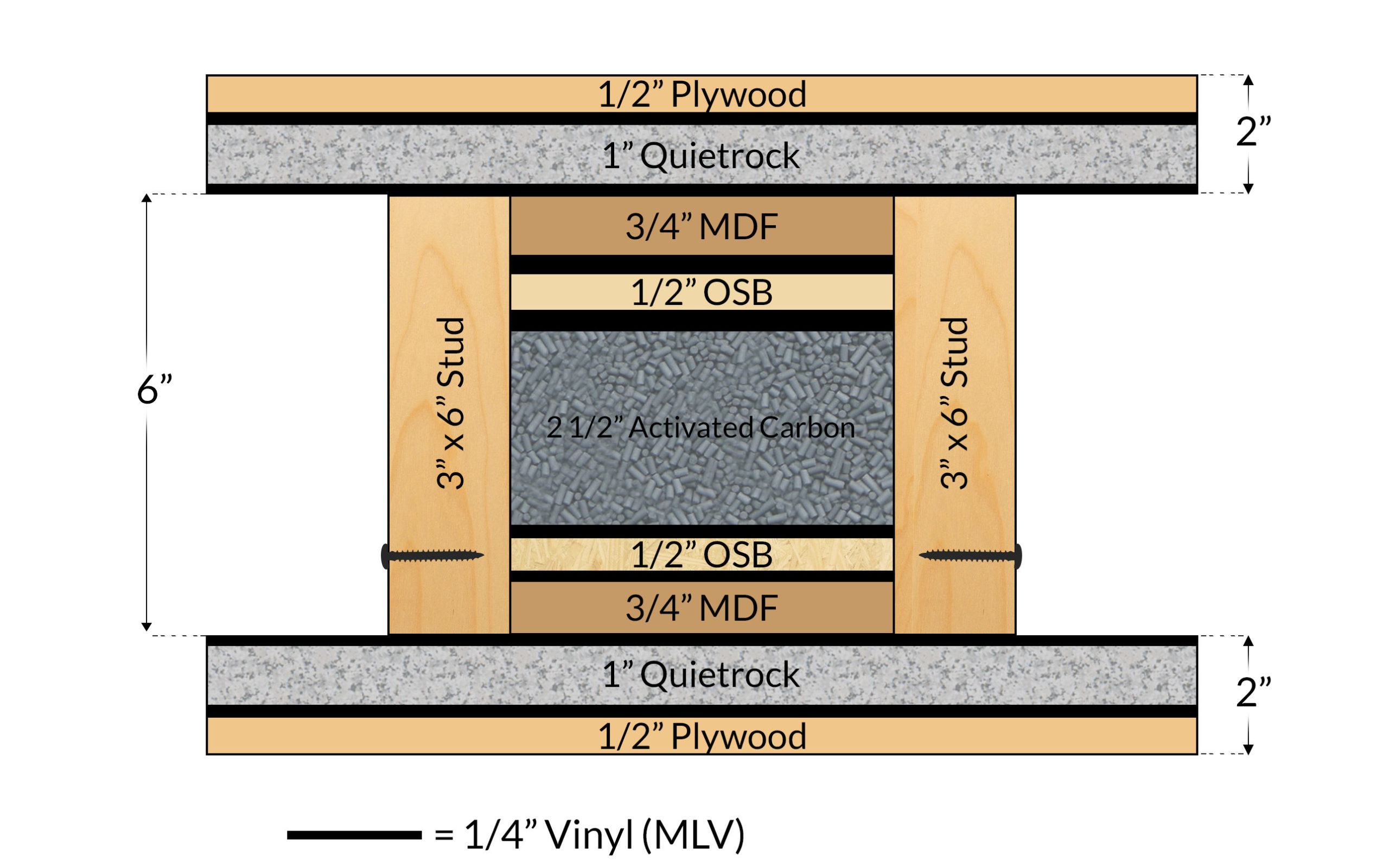

To stop this energy type you need walls that are thick and heavy. Most studio walls we build for control rooms have a STC rating over 90. To accomplish this very high range of attenuation at frequencies beginning at 30 Hz. and going up through 20,000 Hz. , we use a multiple layered approach. When you are dealing with noise that is transmitted through the air and then striking a wall structure, you are dealing with two forms of energy both with similar vibrational signatures but with different amplitudes. The real time signal of noise moving through the air has its own frequency response. When that frequency response strikes our wall or barrier, it becomes a different animal. It is like when a butterfly becomes a caterpillar. It flies through the air unimpeded and then when it strikes the wall it turns into a vibrational signature with a much smaller frequency response. Our goal with any barrier wall is to reduce the vibration transmission of the wall. We do this by slowing the truck down.

If you ever have driven in the mountains, you have seen exit ramps for trucks that lose their brakes. The ramps extend upward towards the sky in a 45 degree angle. This incline coupled with gravity slows the truck with no brakes down. There are usually containers of sand or water at the top of the ramp to add more barrier to the truck momentum. We use the same procedure in dealing with noise transmission through our walls. We build a ramp that has many layers of materials each with different densities that will act to slow the vibration of the noise down. This is why you must measure the noise issues within your room so we know what material type, thickness, and construction methodology to use in your barrier design and build.

About Us At Acoustic Fields: https://www.acousticfields.com/about/

I’m in desperate need of help in my jam room. 24’x24’ space with 11’ ceilings, barn siding walls, drywall ceiling, hardwood floor. I want a balanced sound with lower volumes.

Fill out the info. in this link. Include photos of all surface areas: https://www.acousticfields.com/free-room-analysis/