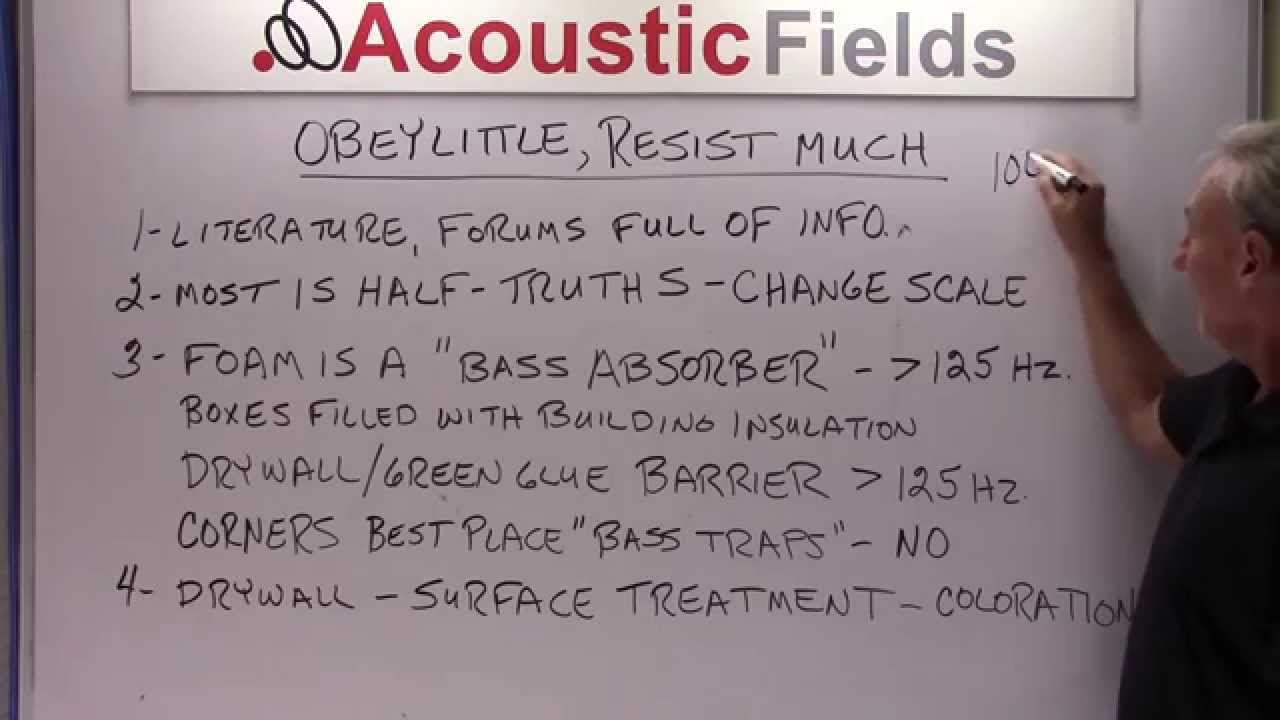

Hi everyone Dennis Floey from Acoustic Fields, today we’re going to talk about obey little, resist much. It’s kind of a saying we have, especially when you’re dealing with acoustics and some of the misconceptions and outright lies that you see in the literature and the forums. They’re full of a lots of information but if you look at the information that they give you it’s just a recycling of stuff that’s in the literature. I don’t see a lot of creativity, I don’t see a lot of people inventing their own technologies, I don’t see a lot of people applying different ways of thinking about things. It’s mostly a manufacture process, like use building insulation to absorb low frequencies, middle frequencies and high frequencies – let’s leave building insulation for building and BTU retention which is what it was designed for and let’s treat acoustics with the respect that it deserves.

So most of the information that you’re seeing is half truth. There is a little bit of truth in some of the things that they say but if you look at a full solution and you try to integrate it into your own usage, I think you’re going to be sadly disappointed.

The first thing we have to talk about is foam as a bass absorber. Nothing could be further from the truth. Foam is good above 125 cycles. If you have a 24 inch deep piece of foam, you’re not going to get much better than 125 cycles of absorption. So be really careful with that.

Boxes filled with building insulation – not bass absorbers. Here is kind of where the half truth kind of exists. When a company can’t design a product to absorb low frequency energy, what do they do? They raise the definition of what low frequency energy is to accommodate their part product’s poor performance. So their product may only go down to 200 or 300 cycles but in their literature and in their minds it’s a low frequency absorber.

Well, it’s not in terms of our definitions. We look at low frequency absorption as anything less than 100 cycles. That’s our definition and we stick to it and our products’ design parameters support that and you can go on our website and look at that.

Here is another one. Dry wall and green glue is the ultimate barrier technology considering cost, materials, ease of installation. Nothing – and let me repeat this – nothing could be further from the truth. I have many many clients call me and say you know I followed the literature, I followed the advice in the forum, I used two pieces of dry wall, I glued them together, I put them on clips, I isolated them in my home theater room. But my wife can’t stand to be in the rooms next to me. Why is that?

Well, because dry wall and green blue technology, at least most of the methods that are described in the literature, they don’t work below 125 cycles. We’ve built rooms and tested them with this methodology. That’s why we don’t use it. In fact, we don’t use any dry wall in any of our builds. Dry wall has a very nasty coloration for mid range. I’ve been in numerous studios here in Hollywood since we moved our company to the Hollywood location and I’ve been in some of the most finest studios, paramount, beautiful studios. 10, 15, 20 million dollar studios. I don’t see a piece of dry wall in any of them. What does that tell you?

So the literature will tell you dry wall and green glue but the people building the 5, 10, 20 million dollar studios don’t use it. So what does that say?

So you’ve got to be very very very careful. You’ve got to read everything, look at the methodology, look at the materials and say to yourself, “wait a minute, you know, I’ve been in dry wall rooms, they sound horrible” – and do your own thinking. There’s plenty of other technologies. If you want some alternative surface treatment areas, call me, I’ll help you out there.

So the dry wall green blue barrier – not bad, not bad cost-effectively, not bad in terms of installation, poor in terms of coloration and poor in terms of isolation above – or below 125 cycles.

So here’s another one – oh this is my favorite. Corners are the best place to put bass traps. Nothing could be further from the truth. Absolutely nothing. Corners can be a good place to put low frequency absorption. They’re not the best place. I have a database of a 116 rooms that have been measured. I would say in about 10% to 15% the areas of highest pressure were in the corners. The other 80%, 85% they’re distributed throughout the room which is dependent on size and volume.

So I think these manufacturers of products use the corners of the room to tell you that’s the best place to put low frequency absorption even though there is no high pressure areas there because you don’t have anything in the corners. So it’s a good place for your to put materials because you have nothing in the corners anyway so let’s put something in the corner. Will they help? Maybe but probably not. Will they help in low frequency absorption? Probably not. So you have to look very carefully at that. Pressure throughout a room is distributed depending on the room’s size and volume. Dimensions are so critical. Speaker positioning is so critical. So you have to step back, take a deep breath and do your own thinking here.

So dry wall, we talked about the coloration of dry wall. So be very very careful here with what’s out there. You don’t see a lot of new technologies, you don’t see a lot of creative thinking. You don’t see taking existing materials and constructing them in ways that maybe minimize their coloration but appreciate their cost savings and construction methodology. So there’s a lot of ways to go. We constantly test different construction methods, we constantly test different materials to come up with stuff.

So realize that you have to do your own thinking and understand what’s going on. Obey little and resist much when it comes to a lot of the things that are in the literature today.

Thank you,

Dennis Foley

—

This is an unedited transcript from our video series from Acoustic Fields. There will be some errors in grammar and sentence structure that occur during this translation process.

For complete understanding and comprehension, please view the video which is included in this text. For any additional information regarding this topic or others relating to room acoustics, please contact us directly at:

P: 520 – 392 – 9486