Much About Nothing

There is much sensationalism and hyperbole when it comes to acoustic products. Claims are shouted about solving this room acoustic problem with the addition of this or that product on this or that wall hanging device. Sound energy issues and the room distortions they create within a small room acoustic environment are never solved. The best objective to shoot for is good sound energy management within the room itself.

“Bass Absorbers”

One of the areas and I think the area that most acoustic companies contribute to is the claims made for low frequency or bass absorbers. First, the name bass absorber is not accurate. We do not absorb bass with current technologies, we absorb some of the bass, never all. It is not as the name implies a complete bass absorption remedy at any frequency nor in any room location.

Low Frequency Definition

Another area of concern in the literature is the definition of low frequency. Is low frequency and bass the same? I went into a group of different audio forums and asked for a definition of low frequency. I received 18 responses, all with different answers. Many acoustical product’s companies have artificially generated newer and much higher frequencies ranges for low frequency and this “frequency creep” in always in an upward direction that tends to favor that specific companies developed product. I have even seen 400 cycles labeled a low frequency. Really?

Low Frequencies < 100 Hz.

Lets focus on frequencies below 100 Hz. and use this as our domain. There are few absorbers in the marketplace that go into this range and are designed for operating only in this range. Absorption coefficients and even Sabins measured do not show much absorption activity at 30,40,or even 50 cycles. With these necessary levels to be reached, we also need to absorb at a rate that has a sonic impact within our room. A faster rate is much more desirable, since we are asking a small amount of real estate in the form of an absorber, to deal with 30 and 40′ waves of energy.

Sound Management

Deal or manage the energy is what our goal should be. We can not control it to a point that it is ruler flat throughout the entire 20 Hz.-20,000 Hz. range. We can reduce pressure levels and lower their amplitudes, so that we can force the room response into some type of acceptable parameter. Room acoustics and the treatments that go with it are always about compromise in some form or another.

Helmholtz Resonators

There are many different ideas on what constitutes a low frequency absorber design. Two basic designs that have stood the test of time are Helmholtz resonators and diaphragmatic absorbers. A Helmholtz resonator is a coke bottle. It is a cavity that is filled with air and that cavity has a specific length. Air inside the cavity reacts with air at the neck opening and this creates a spring type action. Change the length or volume of the cavity and one can change the frequency. A 8 oz., glass, coke bottle resonates at 185 Hz.

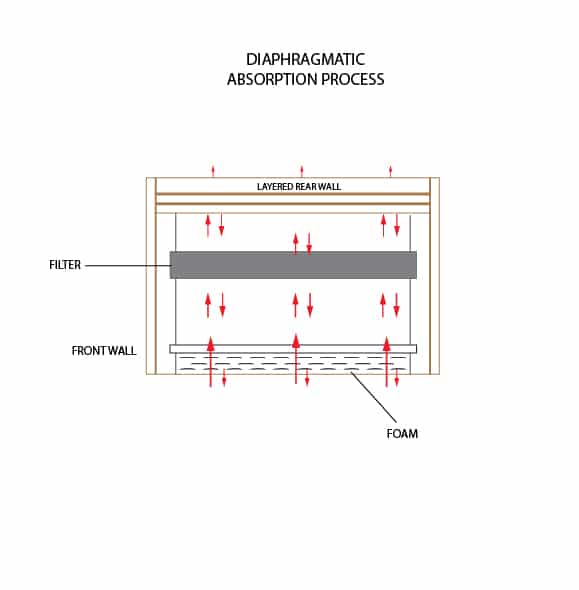

Diaphragmatic Absorption

A diaphragmatic absorber is a little more complicated but works on a similar principle of resonance. The air inside our cabinet or diaphragmatic absorber works in sympathy with the movement of the front panel or diaphragm. This vibrational dance slows the air movement of the wave down as it enters the cavity or cabinet center. Inside the cabinet is sound absorbent material that not only must absorb the resonances generated because of internal cabinet dimensions but it also must “over absorb”, so that it lowers the cabinet’s Q value by a large amount.

Cabinet Surface Density

The density of the cabinet walls, the depth of the cabinet, and cabinet fill material are important in the overall performance of a diaphragmatic absorber. If one increases the cabinet depth and increases wall density along with it, lower frequencies of resonance can be obtained. Frequencies above the cabinet’s resonant frequency will be absorbed.

Cabinet Fill Material

If one uses a cabinet fill material that is highly absorbent, higher rates of absorption above the cabinet’s resonant frequency can be obtained. The cabinet’s density and depth determine the level or frequency of resonance of the unit, but the quality of the internal cabinet fill material is critical to how fast absorption occurs at any frequency above the cabinet’s designed for resonant frequency.

Cabinet Fill Rate Critical

The internal cabinet fill has an impact on the rate of absorption above the cabinet’s resonant frequency. At lower frequencies within our small room acoustical environments it is favorable to have as low as level or frequency as we physically have space for within the room. It is also good to absorb that energy as fast as possible within the space confines we are given to work with. This increased rate comes with proper fill testing.

Walter Sabine

To determine if a “bass absorber” is capable of absorbing at its sated frequency of resonance and beyond one must look at a unit of measure termed a Sabin. A Sabin was named after a famous and well respected engineer called Walter Sabin. A Sabin is a unit of sound absorption. Think of one square foot of an open window as having a Sabin value of one. An open window regardless of size is a perfect absorber because once sound passes through it does not return. It is gone forever, unless of course you live in Manhattan where your neighbor’s building is 6″ from yours.

Sabins Above 20

A good bench mark for comparing low frequency or bass absorbers as they are called in the literature is to look at how many Sabins are absorbed by the companies testing procedure or lack of procedure. If one does not see Sabin measurements above 20, especially below 100 cycles, then one will need a lot of these units to have an impact on any low frequency issues.

There is a lot of confusion in the sales literature when it comes to low frequency absorbers. Low frequency definitions are created to suit the individual companies product’s performance. A good, low frequency, energy absorber will be as large as a floor standing speaker and probably weigh more, but if designed correctly can assist one well in managing low frequency issues in our small room environments. It may be big and heavy but it will earn its keep.