We have updated this blog on 12/1/19 to reflect new knowledge and experience in how to soundproof a door.

Our doors provide many functions. We must open and close them to exit and enter the room and when we close them, we expect them to offer some control with the transmission of sound energy from one room to the other. Doors need to be viewed as a barrier between different sources and levels of sound energy. So working out how to soundproof a door correctly is a very important step especially if your control room needs to have access to a busy street.

Put A Number To The Noise

First, we must measure, using the control room / busy street access example, the amount of energy that we need to reflect back to the source with our door barrier. What is the noise level in our control room going to be and how much energy from the street are we going to have to reflect back into the live room. We must put a number for each room’s noise. That number tells us how thick of a door, barrier, we are going to need. Measurements and the numbers they produce are directly associated with construction costs. We must be accurate and take many measurements over numerous time periods when different pressure levels occur, so we can design the appropriate barrier technology. Measure the amount energy in your room is a crucial first part in how to soundproof a door.

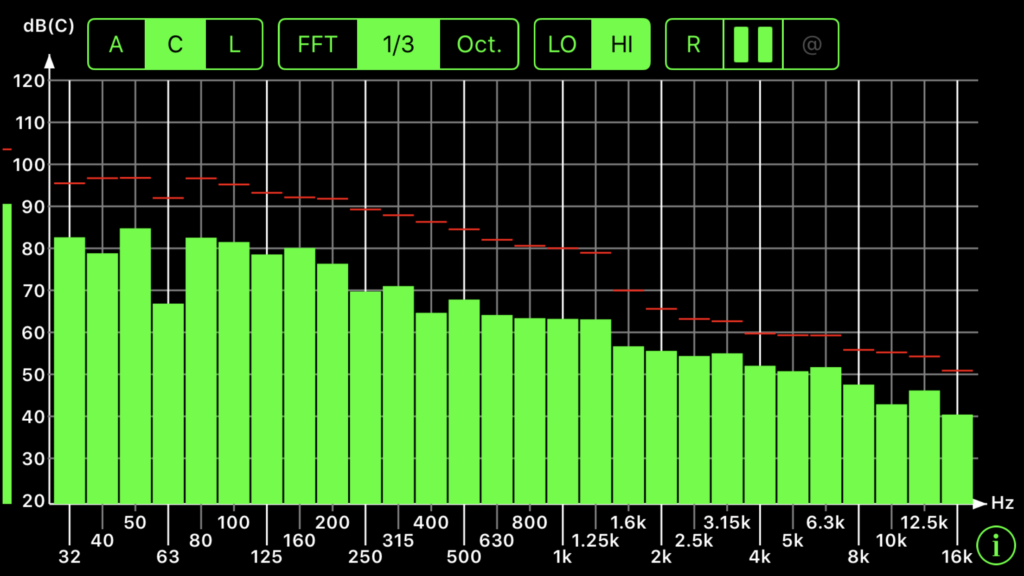

Octave Bands

Step by Step

How to soundproof a door has to be a step by step process. First, we must define how large of a sound pressure issue we must be dealing with. Let’s use a control room door as our example. Our goal will be for “quiet please”. If the control room door is next to street access we must make sure that that energy from those two sources does not enter into our control room. Control rooms should have ambient noise levels no higher than 40. Thirty is much better. This is a large difference if street noise is 70 – 75 dB. We need a barrier that can at least stop 40 dB of sound energy.

Measure, Measure, Measure

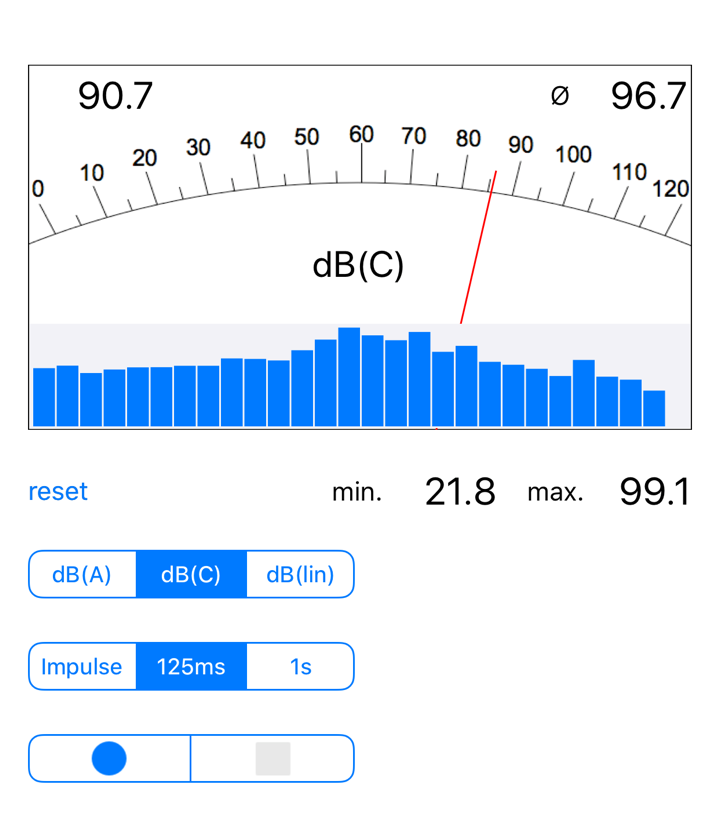

We must always quantify and qualify all noise issues through measurements. We must measure the frequency and amplitude of all noise issues. We must take the lowest pressure reading on each of the seven days. We must take the highest pressure reading on each of the seven days. With minimums and maximums, we can design for the maximum and be safe with the minimums.

dB Reading

Door Sound Lock

Our first thought must go to a sound lock. It will be the most powerful way to isolate this sound noise. We must construct a little room between two doors that is the “lock”. A control room sound lock is similar to the airlock on a spaceship. One is placing a barrier between air or lets say no air in the case of space and one is placing an air barrier for sound from the control room and the live room. What we will have is two doors separated by a small room. We want a minimum distance for our airlock of 3-4′ between each door.

Door Lock Construction

The sound lock that will be the small room between two doors, must be treated as its own room and maximized in performance from an acoustical perspective. Its acoustical size must be taken into consideration and dealt with. The inside of our “room” must be treated with the correct acoustical treatment both for low, middle, and high frequencies. Obviously, the barrier side of the structure must also conform to sound transmission loss principles. Isolation technologies for the airlock shell and sound absorption technologies for inside the “lock.”

Door Construction

The doors on each end of the sound lock must be constructed of numerous layers of materials. We want to create a structure with our door that is vibrationally inert. It must not vibrate or vibrate very little when sound energy strikes it. We will use a technique termed constrained layer, mass damping. Multiple layers of materials will be assembled in such a manner that sound transmission loss is maximized at all frequencies.

Constrained Layer / Mass Damping

Constrained layer, mass damping means that we arrange different materials with different densities next to each other and create a “sandwich” using all of these materials. materials must be chosen that have specific densities and these materials must be arranged in a way and pattern that reduces vibrations. Vibrations are created when sound pressure energy strikes the door and causes it to vibrate. We must minimize vibrations to ensure adequate sound transmission loss from one side of our door to the other.

Bank Vault Door Used in a Studio

Many Layered Sandwich

To minimize our vibrations, we create an obstacle course that vibrations must travel through with our door construction. Our goal is to interrupt the vibration signal transmission as it moves through our from outside noise sources to our interior control room. If we arrange materials of different densities next to each other, like layers of meat in a sandwich, we then surround each layer with a vibrational damping compound that is designed to absorb structural vibrations. The layering of materials with different densities, layered with damping compounds, will provide us a solid, relatively inert structure for our door barrier. Make the door at least 4″ thick following this procedure.

Bank Vault Doors

Once you have built your sound lock and your constrained layer, mass damped door, you are ready to install one on each end. Place it upon two pressure bearings top and bottom of the door centered. Make each door 36″ wide. Install long handles so that the door moves easily on the bearings, just like a bank vault door. Place a portal or round window in the door during construction, if desired. Use two 1/2″ thick panes of safety glass separated by as much air space as your door thickness will allow. Make sure your bearings are rated at least twice the door weight capacity. Make sure all edges of the door seal upon closing. The smallest hole can ruin everything.

Synergy Of Technologies

Building a sound lock between two doors to isolate noise from higher sound pressure levels is the ultimate way to isolate. We have space, air, absorption, and barrier technologies all working together, each operating at their maximum performance for their respective technology. Oh, yes, don’t forget about how cool the bank vault door is with the round portal for a window. You will be able to move 1,000 lbs with one finger strength.

About Us At Acoustic Fields: https://www.acousticfields.com/about/

In Summary

If you have any questions follow up questions on how to soundproof a door please feel free to email me and I will be happy to help. Please message me at info@acousticfields.com. If you want to learn more about room acoustics please sign up for our free acoustic video training series and ebook. Upon sign up you will have instant access to the room acoustic training videos and ebook to help improve the sound in your studio, listening room or home theatre.

Thanks

Dennis