DIY Bass Traps. Updated on October 25th, 2019

Bass boom in our rooms can be managed if you know how to make your own DIY bass traps. You can make your own DIY bass traps by following what is online. These are usually boxes filled with building insulation which is meant to keep your room and cold and warm not to absorb the bass. Building insulation is for buildings and BTU retention. You can buy foam wedges that are called bass traps, but then you soon realize that a foam wedge would have to be 11′ thick to absorb a 100 Hz. wavelength completely, so how much bass does a foam wedge that is 8″ thick absorb. The answer is none.

How To Make Your Own Bass Traps

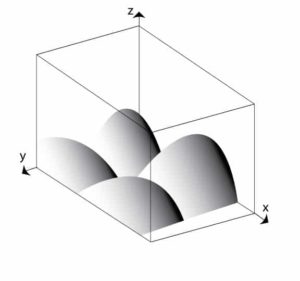

You can purchase so-called bass traps by acoustic product manufacturers and then get then home or in your studio only to find that they are only called bass traps because they sure do not absorb any bass. You can place the bass traps in the corners of your rooms where most manufacturers suggest and then realize putting bass traps in the corner is only the beginning. Any acoustic engineer worth his salt will tell you that bass traps must be spread throughout the room to produce a smooth and balanced sounding room. This is because the pressure zones created by long low-frequency waves are everywhere in your room. A 30 Hz. wave will be 37′ in length. How is just placing something in the corner going to treat a whole wall frequency issue?

BDA Broadband Diaphragmatic Absorber

Acoustic Fields Diaphragmatic Absorber: https://www.acousticfields.com/product-category/sound-absorption/acda-series/

Room Modes

Room modes are everywhere in your room. Room modes are high and low-pressure areas that exaggerate certain frequencies or swallow others like an acoustic black hole. None of this exaggerating or smothering is except able if our goal is a nice and even frequency response in our room which it must be. Low-frequency energy pockets can be absorbed with DIY bass traps but the bass traps must be built using the correct technology to have the strength to produce the required rates and levels of absorption to qualify as a real working bass trap. Forget about foam wedges, tubes, and boxes filled with building insulation. You can build your own units, and be shown how to make bass traps from a time tested and proven method of low-frequency absorption called diaphragmatic absorption. Diaphragmatic absorption has been working for over 40 years.

Diaphragmatic Absorption: Time Tested And Proven

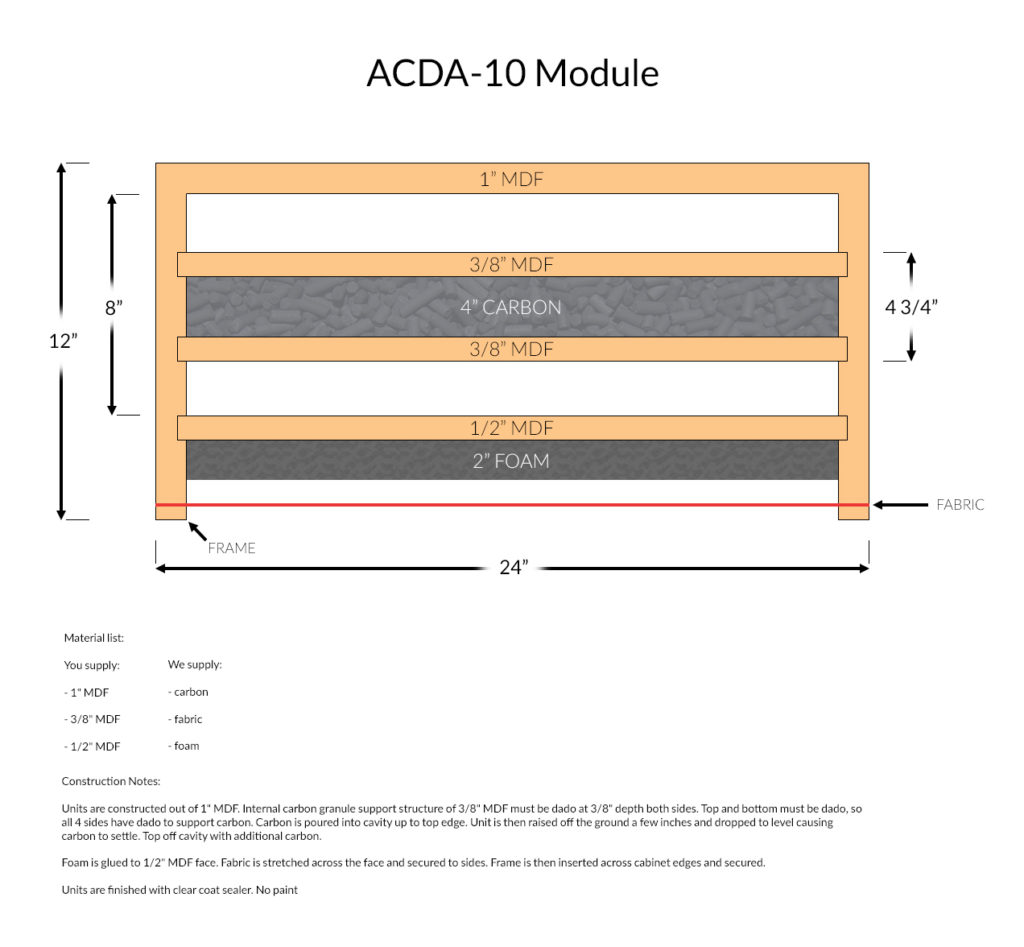

Diaphragmatic absorption is really two sound-absorbing technologies within one. The first outside cabinet has a dense shell with a front wall of lesser density. The rigid cabinet and more flexible front wall work together to force the front wall to do all the moving while the cabinet stays vibration-free. When the low-frequency wave strikes the cabinet face, it starts to slow the energy wave down. It then enters the inside of the cabinet and must deal with the pressure changes within the cabinet.

This video explains this technology further:

This bending slows the long, low-frequency wave down before it enters the cabinet insides, where it comes into contact with another form of sound-absorbing technology called a perforated absorber. The perforated absorber has been designed to absorb all the internal cabinet resonances along with contributing to the overall bass trap’s performance and to lower the pressure inside the cabinet. It is a complicated technology to design and build but it is the go-to the technology used by professional recording studio builders for the last 40 years. What if you had step by step instruction to build one of these professional-level sound absorbing units for your own music room?

You Can Make Your Own Bass Traps

What if you could have this time tested and proven real low-frequency sound-absorbing technology described in a way that you would immediately know how to make your own DIY bass traps by just following the text and photos? What if every piece of material was sized for you and all cut measurements were listed on a cut sheet? What if all tools you would need to have on how to make bass traps were provided in another list?

What if each step by step assembly instructions were accompanied by actual photos of a unit being built and the photos illustrated the text for you? What if the design allowed for you to place your choice of middle and high-frequency sound-absorbing material on the unit’s face in your DIY bass traps? What if the unit’s overall performance ratings were based on actual production units, which have been tested and verified at Riverbank Acoustical Laboratories?

Don’t Compromise Performance

No need to purchase products that have minimal performance and pay full retail for them. If you have basic carpentry skills or know someone who has you can have your own diaphragmatic absorber. With our DIY – BDA build plans for our diaphragmatic technology, you will know how to make bass traps. These DIY bass traps can have all the latest advances in low-frequency management technology and you can make your own time tested and proven technology that has been used by studio building professionals for years.

There is no need to compromise with boxes filled with building insulation, tubes, or foam wedges that do not absorb low frequencies at all. With our DIY bass traps build plans you can build your own low-frequency absorber that will actually absorb low frequencies with minimal material costs and just a little elbow grease. Go grab them here and build your own real solution to the bass issues in your room once and for all.

How much will it cost to build your own BT (per unit) according to your plans?

V, Here is the material cost breakdown for the BDA / DIY. 1 full sheet 1″ MDF @ 50.00, 1/2 sheet 1/2″ MDF@ 25.00, 1/2 sheet 3/8″ MDF @ 25.00, carbon 300.00, foam 75.00, Fabric 50.00 Total 625.00.Labor: 20 – 25 hours / unit. If you buy 8 or more from us the cost is 800.00 / unit plus shipping to your area.

Hi Dennis, I’ve purchased the plans, unfortunately Carbon is out of the budget, what is the test result performance of the Diaphragmatic Bass Trap using FOAM only design?

Thanks

Carbon insert increases performance of the foam insert by 40%. You will need to build two units without carbon to have the same performance as one with carbon.