Today we’re going to talk about how to build a recording studio door or as some search for a soundproof studio door. Advancements have been made in the science of barrier technology. We have updated this blog on 11/13/19 to reflect those changes. We receive a lot of questions about what’s the correct technique, what materials to use, how thick should it be and many others. The answers to all of these questions are found in the noise.

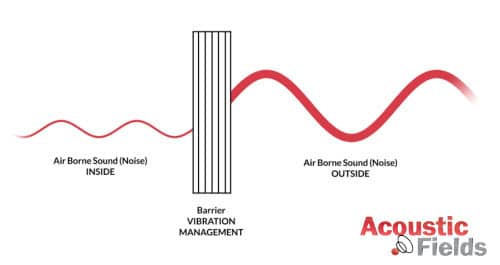

What is a door for? Let’s think about it. Its purpose is isolation from noise. We want to keep the noise that is produced outside our rooms to not enter our room and we want the noise inside our room to not leave our room and bother others Structures that are built to isolate occupants from noise whether it is a recording studio door or a soundproof studio door are using barrier technology. Barrier technology is vibrational acoustics.

Barrier Technology

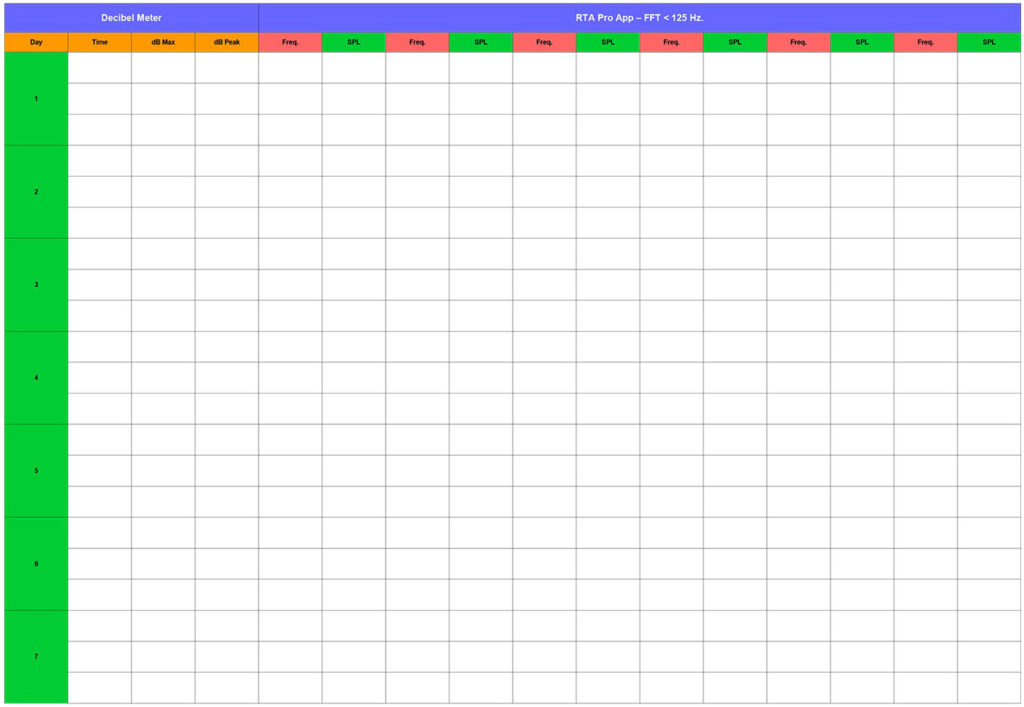

Barrier technology is based upon numbers. You must measure your noise issue. You must measure your noise issues over 7 days. You must record the frequency and amplitudes of all the noise issues. You take measurements during the quietest part of the day and then the noisest. This gives us a minimum and maximum pressure level for each day along with the frequencies that are causing the issues at those times of day or night.

A lot of mix engineers like to mix late at night and into the morning hours. The noise levels outside at 2 am are much less than at 3 pm in the afternoon. The ambient or background noise can drop 20 dB SPL from the daytime levels. This work time must be measured for noise output from the room. The noise you generate during the day may blend into the ambient or background noise but at night it can be the elephant in the neighborhood. I have clients who have been fined thousands of dollars for violating neighborhood noise levels. One client lost his studio. The city made him shut it down.

Two Room Parts

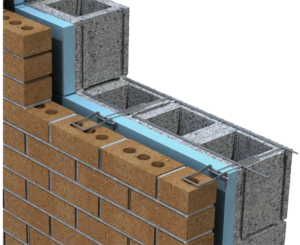

In any critical audio room, we have two main parts. We have the shell which is the barrier technology to isolate from noise. Its function is to reduce noise transmission from the inside of the room to the outside and keeping noise generated from outside where it belongs. The interior structure is called the treatment room. This is the absorption and diffusion technology to reduce unwanted pressure amplitudes throughout the room and manage the reflections from the four walls, floor, and ceiling. The process one uses to build the shell or barrier is the same process we use to build a recording studio door and a soundproof studio door. A lot of people confuse treatment technologies with barrier technologies. One treatment technology that gets confused all the time is open-celled foam which is a treatment technology designed to absorb middle and high-frequency energy to manage reflections.

Low-Frequency Barrier Design

Foam Not Barrier Technology

Foam is not a barrier. We get a lot of questions “ Can I just put some foam up and that would be a good door?” No, foam is an airborne middle and high-frequency absorption device. It doesn’t have anything to do with the structural vibrational issues. No foam for doors. You can place the foam on the door inside your audio room to absorb excess middle and high-frequency energy from your speakers.

Acoustic Foam Panels in Studio

Door Materials

What are we going to build our door with? What’s the process we’re going to use? We’re going sandwich a bunch of layers of material together. We’re going to use a process called constrained layer mass dampening. However, what material types we use, how many types and how thick each type all are based upon the frequency and amplitude issues we will take with our iPhone. Remember we must have noise measurements during the times of room usage. We must measure noise produced within the room and what the ambient or background neighborhood noise levels are.

Data Recording Sheet for RTA Pro App

Balancing Act

It’s a balance between density, flexibility, and rigidity. You just don’t slap a bunch of materials together or glue a bunch of materials together and hope that you can get a good result. These are scientific calculations based on the quantifiable levels of noise that you have to deal with. Everything is related. There is no one solution that fits all problems. There is no universal answer here as it all depends on the amplitude, in the frequency of your issues that you’re dealing with. Certain materials of certain densities work for certain frequencies.

2 Types of Barrier Technology

Barrier technologies come in two animals, one that works below 125 cycles, one that works above. Completely different approaches, completely different structures, completely different costs, completely different weights. Everything and I mean everything is different depending on the frequency and the strength of your issue. We’re going to use a bunch of layers of material to control vibration. We’re going to change from airborne to vibrational energy and we have to use a series of layers to deal with that. These are two sciences with some overlap. However, the key to understanding each one’s application correctly is in the differences.

Middle/High-Frequency Barrier Design

Air Lock

Another way to do it is to create an airlock. We’ve all seen these on shows like Star Trek where the outside environment is the vacuum of space and the inside is habitable. To get between the two environments, you go into a little airlock, close the one door for that human habitat and then open the other door to the vacuum of space. That’s called an airlock. We can do the same thing with our studios when we are building a recording studio door or a soundproof studio door. So we construct the door, we leave some space and then we construct another door.

Sound Proofing: https://en.wikipedia.org/wiki/Soundproofing

Acoustic Transmission: https://en.wikipedia.org/wiki/Acoustic_transmission

In the following graphic, we realize that airborne energy is converted to vibrational energy and we have to use different processes to deal with it. Vibration management concerns the slowing down and reducing the vibrational energy as it moves through the material of our door. We also have to realize a good sound is a combination of doing a lot of little things correctly and in the right order. We place the highest density layer of our sandwich on the outside of our door so noise can’t come in and we do the same to the inside of the door to keep the room noise within the room.

In Summary

To learn more about room acoustics please sign up to download our free ebooks and video series on room acoustics here. And please let me know if you have any questions at any time.

Thanks

Dennis Foley

Love the articles.

Hi Dennis, Thanks for your support. If you would like a certain topic covered, just let us know.

Hi Dennis,

This is a shot in the dark but I’m wondering if you could help. My office has a recording studio and we like to prop the doors open occasionally. The walls are backed with steel and the door with lead so we’d prefer not to drill any holes and the door has silicone flaps on the underside so a rubber wedge may damage the integrity of the flaps over time and they’re simply not strong enough to hold such a heavy door.

Currently, we’re using mic stands to prop the doors open but they slide underneath the door and can potentially ruin the flaps. One solution we came up with was to buy a 25lb kettlebell (rubber coated) but that’s a bit pricey, at nearly $30 a pop.

Have you have run into this issue and if you have, can you recommend any cheap alternatives? I’ve seen wedges that can be inserted near the hinges but I’m not sure if they could hold up against such a heavy door.

A, How fortunate you are to have steel walls and a lead door. I am jealous. When was this studio built? Use an eye hook female in the door and a male in a wall. If you don’t want to drill into the door, glue a wood block to door with flex seal adhesive and screw into that with the female eye hook.