Time Tested Technology

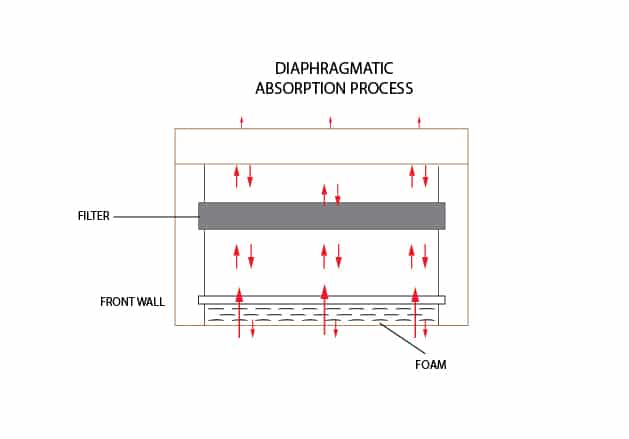

Diaphragmatic absorption has been around for a long time. If you have a drywall covered frame wall in your house or studio and you probably do, you have a diaphragmatic absorber. A diaphragmatic absorber is a sealed unit that has a front wall, internal cabinet fill material, and a rear wall. The sides, top, and bottom round out the units construction. It does not need holes to work. A 40Hz. wavelength that is 26′ long does not care about any holes, no matter what their size.

Traditional Diaphragmatic Absorber With Single Front, Side, And Rear Wall

How Does It Work?

Sound energy strikes the face of our absorber and gets slowed down in the process. It would be similar to running a marathon and getting a cramp in your leg. You may finish the race, but you will not be operating at maximum strength when you cross the finish line. Once we slow down the long waves of low frequency energy, we can more easily manage them before they enter the inside of the cabinet where they will meet a zone of severely reduced pressure. Its like a pilot leaving the earth’s atmosphere and entering outer space.

Theory

A diaphragmatic absorber has a front face that, you guessed it, acts as a diaphragm. A diaphragm can be thought of like a speaker. A speaker moves back and forth to create energy. The face of a diaphragmatic absorber moves back and forth in order to absorb energy. Obviously, the speaker moves back and forth because it is driven by electrical current. The face of a diaphragmatic absorber moves in response to sound pressure exerted upon it by low frequency energy waves. It does move but you can’t see the movement.

Engine Important

The internal cabinet fill creates a sound absorbing environment that will assist us with our performance. Once inside the cabinet, the energy level of the wave is further absorbed by its energy changing from mechanical to heat. Once it is converted to heat, it is lost forever. We want to heat things up as much as possible with our internal cabinet fill material. We want to make it run through the Arizona desert in the summer without catching fire. We do that by making it more efficient.

Slap In The Face

Once low frequency energy strikes the face, it starts the absorption process. The movement of the front wall or diaphragm, slows the low frequency wave down before it enters the cabinet. When it enters the cabinet, the magic happens. The inside of the cabinet has a filler type material that has a high degree of absorption. It is too much absorption in a small area. It is too much, but it needs to be. Its goal is to lower the cabinet’s Q value.

Q Value

Lets think of Q value as a process that takes an existing space such as the inside of the cabinet and makes it work much better than it’s size would indicate that it could. The internal cabinet fill material provides so much absorption in the small space of our absorber, that one could use artistic license here and say that the internal cabinet fill material sucks the air out of the cabinet and creates kind of a vacuum. This lowering of a cabinets Q value is done through a process called acoustic compliance enhancement.

What Frequency To Work At?

To calculate the resonant frequency, the frequency our absorber will begin to absorb at, we use three main variables. We need the cabinet diaphragm(front wall) density or weight. It must be a certain weight to work well with the other variables. We next look at cabinet depth. The depth of the cabinet is critical in determining how low we can absorb at. The internal cabinet fill must be of high enough absorption performance that it absorbs all the internal cabinet resonances and then some more. We want it to overreact act like using a roll of paper towels to soak up a glass of water that was spilled.

Formula Required

There is a formula that we use to plug all of these numbers into and get the general resonant frequency of the cabinet. The greater the density of the front diaphragm, coupled with the cabinet’s depth, goes a long way to determining how low of a frequency the absorber will work at. The internal cabinet fill has a direct impact on the rate of the cabinet’s absorption. The cabinet face density and the cabinet depth, determine the operating frequency of the unit. What you put inside the cabinet, determines how fast the diaphragmatic absorber absorbs all the energy above the designed for resonant frequency.

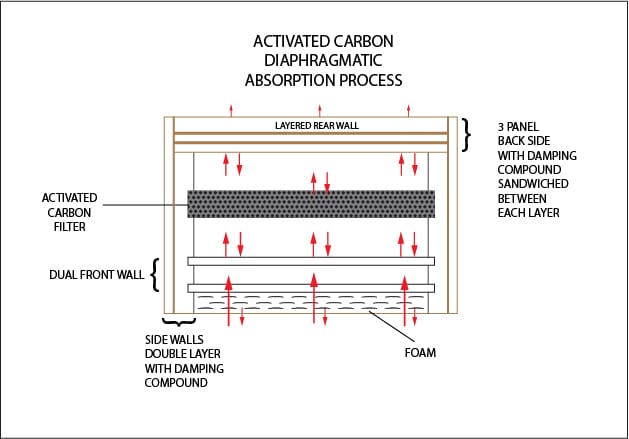

New Technology With Two Front Walls, More Rigid Side And Rear Wall Along With Activated Carbon Or Charcoal Internal Cabinet Fill

Three New Ways

We can improve upon the traditional diaphragmatic absorber technology in three critical ways. We can take a Buick which is current technology and make it run like a Ferrari. If we have two diaphragms or front walls, we get twice the impact of just one wall. Remember, the goal of the front wall or diaphragm is to slow the wavelength down by moving in sympathy to the pressure exerted upon it.

Air And Mass

If we have two walls, we can slow down the energy at a faster rate. If we carry this further and adjust the densities of each new wall to move together in a sympathetic movement, a synergy effect happens where two walls do not just work twice as well but work say, 5 times better. Calculating the proper air space that is required between these two front is paramount so they work with each other and not against.

Better Cabinet Construction

If we increase the density and rigidity of the cabinet, we also can impact more positive change. Our structural design goal with the cabinet is to make the cabinet as rigid as possible, so that it will not flex. If the cabinet does not flex, the front two walls are the only thing moving. We want the front walls to move not the cabinet. The cabinet is the backstop for the reduced energy to strike.

Cabinet Must Not Move

If we use multiple layers of material in building the side walls and top of our unit, we can achieve structural rigidity. Using a process termed constrained layer, mass damping, we sandwich different layers together with different densities. Between each layer of material, we place a damping compound that minimizes layer to layer vibrational transmission. We must also perform this layering technique on the unit’s back side. Increasing cabinet structural strength, forces the front walls to do more good work.

Activated Carbon Engine

Once the energy enters the cabinet inside, it must meet more than traditional building insulation material. If the inside of the cabinet has a very powerful absorber in it, that is powerful on its own without being in the cabinet, then we have created a large reduced pressure area inside our sealed box. This large internal cabinet lower pressure area is achieved using activated carbon or charcoal.

Looks Like Miniature Meteor

Activated carbon has numerous pores that sound can enter and be converted to heat. This is a similar process to open celled foam. Sound enters the open cells of the foam and is converted to heat. The fly enters the meat eating plant and is digested. One can achieve large rates of absorption that will be at levels higher than the designed for resonant frequency of the absorber.

Two Doors Instead Of One

Traditional diaphragmatic absorbers have one front wall or diaphragm. They also have building insulation material inside of them. Usually, the same material and thicknesses are used to build the cabinet itself. They work well for the amount of real estate they occupy, but with a major engine overhaul, can really take off. If we use two walls instead of one and design the two walls to work with each other, we have begun the overhaul. Next, we make our cabinet very rigid with vibrational reducing technologies.

Two Walls Working Harder

Since the cabinet moves so much less than the front walls, the front walls performance increase drastically. Inside the cabinet, we get remove the standard building insulation material and replace it with activated carbon or charcoal. Charcoal is super absorbent. We use it to filter air and water. Now, we are using it to filter sound. We change the internal cabinet fill material(building insulation) from 2.5 lbs/cu.ft. to 10 times that. We use it to filter air and water. Now, we are using it to filter sound.

Old And Now New

One can take a time tested and proven method of low frequency absorption, namely diaphragmatic absorption, and overhaul its engine with structural and internal modifications to make it work many times better. One can achieve lower levels of absorption with much higher rates of absorption at those levels. Our absorber runs faster and absorbs more energy all within the same amount of real estate as standard diaphragmatic absorbers.