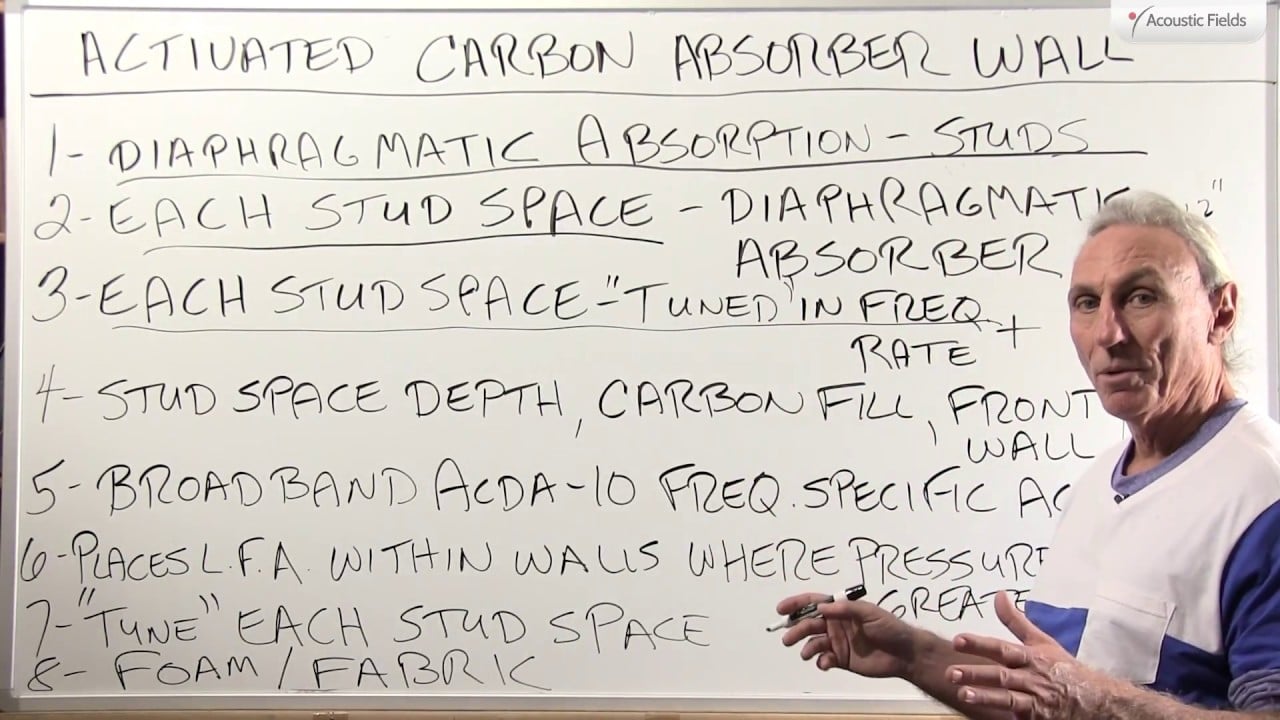

Let us talk about our Activated Carbon Absorber Wall. Plenty of information on our website about it but I want to walk you through it because it’s for people that are building a new room and they’re going to frame it out with wood, that’s what we always use and our standard method is studs obviously 16 inches on center in the United States and we’re going to use a 2 inch by 12 inch stud to frame our room all the way around the four walls and the ceiling because all must be treated. So we’re going to build our technology in between the studs okay, how do we do it?

Well we’re going to turn each stud space into a diaphragmatic absorber, I won’t go into the diaphragmatic absorption process but if you think about a stud space with two studs those are the sides of the cabinet, the back material whatever that is, is the rear of the cabinet and then we put a face on it so we’re really building individual cabinets or units within our wall. Now what’s the advantage of that? Well the advantage of it is each stud space that’s 14 ½ wide we can tune to manage that frequency and strength of that energy within that part of the room because when you pressure map a room you realize that 40 cycles is a problem here, 60 cycles is a problem here, 80 cycles is a problem here and all of that changes in the room depending on usage size and volume so by creating a wall within the room that wraps the room all the way around and the ceiling we can actually pressure map, figure out where the frequencies of issue are and tune that particular area within the room to the problems that are in the room and we don’t need freestanding units sitting around taking up a lot of space.

So how do we tune? We tune by the depth, how much carbon we put in it and how thick we make the front wall when we enclose the stud space. So all of these variables then you can look up the process of diaphragmatic absorption, density, depth of cavity, internal fill material all contribute to the performance in that specific area within the room. So the bottom line here is we have tuning capabilities within our structure. What a great thing that we don’t have a bunch of freestanding units sitting around taking up space because its real estates are valuable. We did a little cost analysis the other day on a project and the guy wanted a breakdown in cost between building it in, framing the room out, building it in versus the same amount of space with freestanding units and it was about three to one meaning that the freestanding units would cost three times what you could do with inside the walls.

A lot of us don’t have that option, we don’t have money, we don’t have space to build a new room but this process is for those that have the ability to build it and what I’m saying to you we can cut costs by sixty percent and get better performance and have a larger room so this is definitely the way to go of your building of room. So we have our two technologies, we have our ACDA10 which is our broadband from 30 to 400 and then we have the frequency specific ACDA12 which is the 30 to 50 cycle range. So we have two tools and all kinds of ranges in-between those that we can control by varying the depth of the cavity, the thickness of the carbon filter and the density of the front wall that we put on the each stud space or each unit. So it places the low frequency technology in the places in the room where it’s the greatest because the pressure is always trying to get out of the room, it’s always trying to be free, it’s always trying to be escaped so when it’s created by a source whether it’s an instrument, a speaker, doesn’t matter what the source is, it moves out against the walls and then that pressure area the walls is the greatest and it is greatest in certain areas at different frequencies and different strengths so by having a 14 ½ inch tunable area for every two inches so to speak because that’s the thickness of a stud so 14 ½ – 2, 14 ½ – 2, 14 ½ – 2 all the way across the wall surface we have the ability to really tune this room so it’s nice and flat.

We can get our rooms down to 1 DB across the board from 30 cycles and if you doubt that come to our sacred mountain Studios in Los Angeles California and I’ll prove it to you because that’s what we did in that studio and we didn’t build that room that was an existing room so you can get an idea of how powerful our technology is. Another thing we can do is on the face of each stud space we can put our foam technology and we can stretch fabric over so you can get a nice balance of absorption in those walls. You can get low-frequency, middle frequency and high frequency absorption tunable throughout the whole surface of the room and the ceiling. So our activated carbon absorber wall is a great way if you’re building a project to save money and get a room with a really nice tight frequency response in the low end.

—

This is an unedited transcript from our video series from Acoustic Fields. There will be some errors in grammar and sentence structure that occur during this translation process.

For complete understanding and comprehension, please view the video which is included in this text. For any additional information regarding this topic or others relating to room acoustics, please contact us directly at:

P: 520 – 392 – 9486