Acoustic foam placement in studios is a complicated subject. It is complicated for many reasons. First, there is a lot of myths around the subject of the foam itself. The industry has done a good job of creating myths about the performance of foams. Many people believe that foam technology is a low-frequency technology when nothing could be further from the truth. Other myths about foam are that foam is a barrier technology designed to reduce noise transmission. Using foam to reduce noise transmission is like holding up a feather to stop a tornado. Foam is none of these things and was never designed to be anything other than a middle and high-frequency absorption tool. Unfortunately, not all foams are created equal and its the difference in their performances that must be addressed in any critical listening environments. Let’s focus on the types of foams and what their usages actually were designed for.

Closed Versus Open: https://www.cgrproducts.com/open-cell-vs-closed-cell-foam/

Two Types

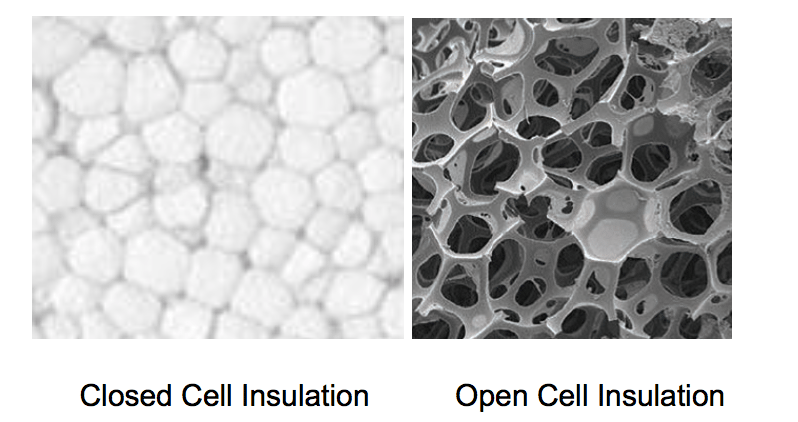

There are two main types of foams. There are open-celled foams and closed celled foams. Open-cell foams are designed to absorb energy at a particular rate and level. These are the foam types we use when we refer to the acoustic foam placement in studios. There are many examples of this foam type in the marketplace. All absorb sound but at different rates and levels. The rate of absorption is how much energy is absorbed in what frequency. The level is how low the foam will go in absorbing frequencies and amplitudes of sound. Closed-cell foam is not for sound absorption. It is designed to use as packing material for shipping items. Closed celled foam is used in pillows and seat cushions for chairs and couches. They are opposite in their performance parameters and are not interchangeable when it comes to acoustic foam placement in studios. You must use an open-celled foam that was specifically designed for music and voice. Music and voice are the end product produced in studios. You must use treatment types, amounts, and positions that work music and voice not against them.

Closed cell foam

Open-Celled Foams

Open-celled foams come in many shapes and sizes. You must realize that no matter what form they take, open-celled foam is a sound-absorbing technology. It is a sound-absorbing technology for middle and high frequencies only. It is not foam for low-frequency or “bass”. Companies market open-celled foams as all types of cure-alls in order to increase sales to the uniformed. I have seen foam called a “bass trap”. I have seen foam called a noise or barrier technology. I even saw one company marketing foam as a noise transmission reduction material. They stated that all you had to do was hang this panel on this wall and all your noise issues would be resolved. This claim is utter nonsense. I have seen foam labeled as a diffuser. This is also nonsense. Foam could never meet the rigid requirements for a truly diffused sound field. Open-celled foam is designed for one thing and one thing only. It is designed to absorb middle and high frequencies. It is designed to absorb frequencies above 125 Hz. However, all open-celled foams are not created equal and you must be careful what rate and level of absorption you use in the acoustic foam placement in studios.

Acoustic Fields StudioPro Foam

Rate And Level

The rate and level of absorption must be addressed when you are considering any acoustic foam placement in studios. We create products from studios that are focused on music and voice. Music and voice are different in their absorption requirements. All of us have been in studios that sound lifeless and dead. This is over absorption. The rate and level of absorption were not properly designed for the requirements of music and voice. Building insulation is a good example of this. Building insulation was never designed to be used as a sound absorption technology. It is another example of how the industry has perverted one industry product that was designed to keep your home warm and cold and use it for the sound absorption of music and voice. It is cheap and many in the industry use it in their products. Unfortunately, most of these materials were created as a substitute for asbestos. However, upon closer examination, you quickly realize that they are just as toxic. Watch the video below on one of many studies that were done in Europe on these material types. For the acoustic foam placement in studios, you must stay with an open-celled foam that was specifically designed for music and voice.

Danger: Mineral Wool: https://www.youtube.com/watch?v=g4Nb2EhxvgM

Acoustic Fields Foam

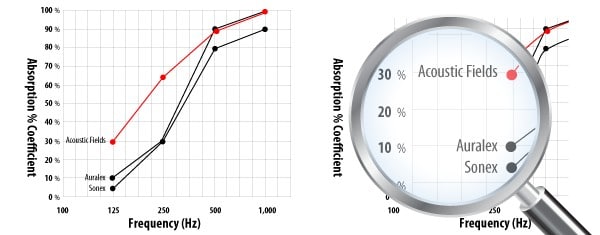

Our open-celled foam took 8 years to create at a cost of over 2 million dollars. It was designed to do one thing and one thing only. It was designed for music and voice. That is the only reason for its creation. It was designed to be the acoustic foam placement in studios that deal with music and voice. It is not designed to keep your room warm or cool. it is not a noise technology to restrict the transmission of noise from one room to another. It is a sound absorption technology that specifically focuses on the absorption needs for music and voice to improve definition, separation, and clarity. Music and voice require a smooth transition between each octave band. You must pay particular attention to the rate and level of absorption from 125 Hz. – 500 Hz. This is the critical octave band and frequency range that has the largest impact on voice and music. Most foams miss this area of absorption. Not only do they miss this critical region from 125 Hz. – 250 Hz. but they over absorb at other frequencies. Notice the smooth transition our foam makes from 125 – 250 Hz. This is the key to our foams performance. It has a smooth rate of absorption starting at 125 Hz. level.

Studio Pro Foam: https://www.acousticfields.com/product/acoustic-foam/

Foam Placement

Acoustic foam placement in studios must occur at the room boundary surfaces. This is the walls, floor, and ceiling areas. You must design for the amount of foam to use and the position on each wall surface area. Every room size and usage is different. For mix rooms, you would place the foam on the front wall and each sidewall. If budget permits. you will place diffusion on the rear wall. If the budget will not permit then you can use foam on the rear wall. For the ceiling area, you must treat the area that starts with the speaker’s rear edge and moves forward across the listening or monitoring position to at least 12″ behind your ears at the monitoring position. For the sidewalls, you need to start at the front wall intersection and go down the sidewalls to past the listening position. Start with positioning the foam 24″ off the floor and going to the ceiling. Use this procedure for the front and rear walls also. To achieve more absorption, install the foam away from each wall or ceiling surface. Use an air gap of at least 3″ from foam to room boundary surface.

About Us At Acoustic Fields: https://www.acousticfields.com/about/