Table of Contents

Introduction

Searching for the term acoustic caulk is like looking for a needle in a haystack. Let’s break down the two words in acoustic caulk. The word acoustic can mean anything. What does the word acoustic mean inside the term acoustic caulk? Let’s look at the word caulk. A caulk is a sealer material type designed to be placed where two material types join each other.

A good example of this process which could be implied using the search term acoustic caulk is to seal the seam around a window frame to the existing wall structure. In this application, one is using “acoustic caulk” to provide a barrier between outside noise and the noise created inside the room. Caulk is a good moisture barrier. However, sound or noise transmission is a completely different physics than moisture prevention.

Noise is like water

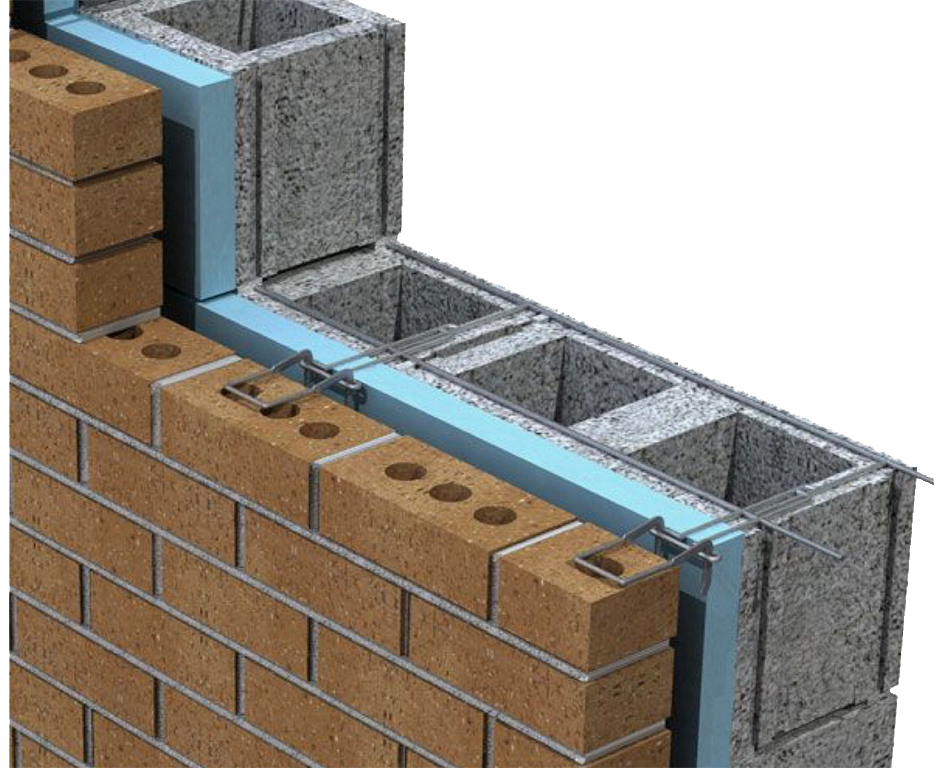

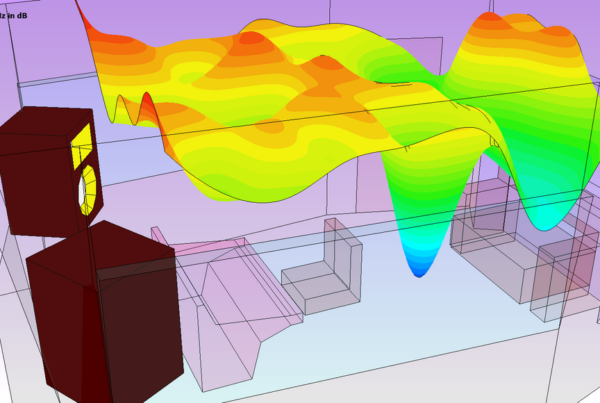

Sound or noise is similar to water. It will find the weakest link in any physical structure and go right through that weakest link. When you are dealing with noise transmission, you are dealing with vibrations and the transfer of those vibrations from air borne energy into solid walls. When the airborne energy strikes the solid surface area, it causes the wall itself to vibrate.

Any material type that vibrates produces noise. When you are addressing noise issues, you are minimizing the transmission of vibrations through solid materials types such as concrete, wood frame, and a host of other building material types. You have a vibration entering a wall and producing more vibrations that must be managed.

Noise Measurement and Barrier Design

At Acoustic Fields, we have a noise measurement process that can be done using your cell phone. We send you the apps. You download them on your phone and take the noise measurements per our instructions. You record the noise data on an online data sheet over a week and send the data to us. We examine the data and send you a drawing of the barrier wall you can build. You can use a DIY approach and build it yourself or you can bid the project out to a contractor.

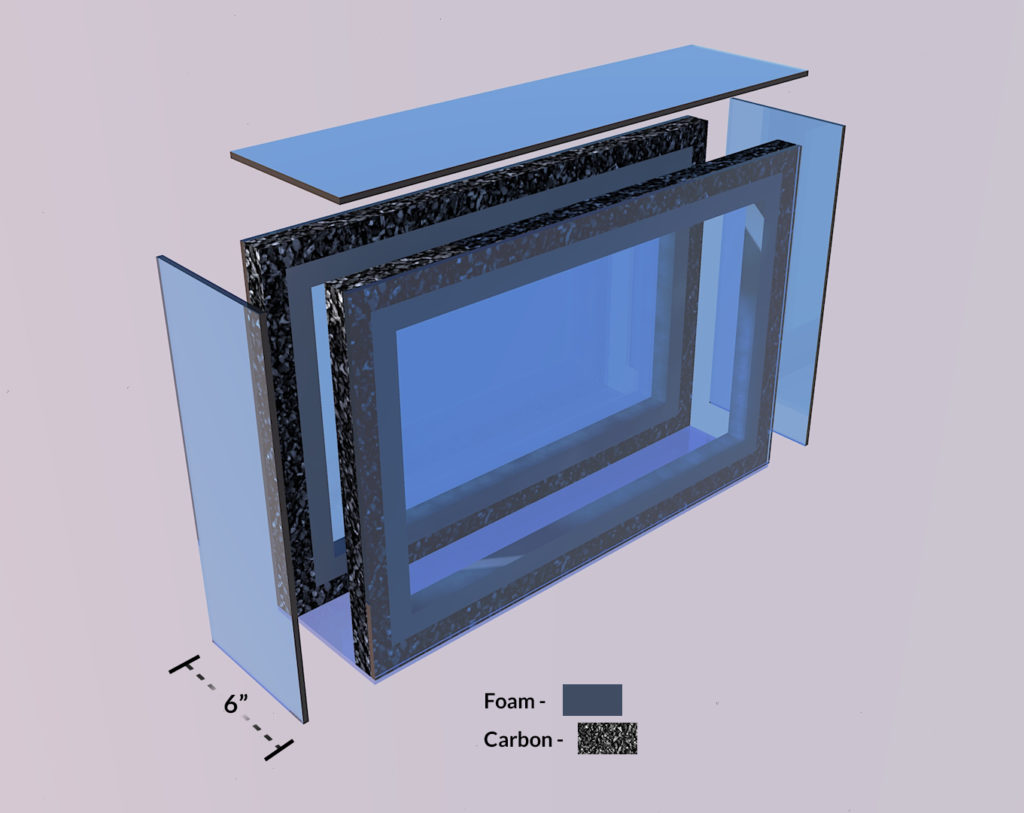

If your noise issues are below 125 hz. in frequency and have large strengths or amplitudes you will have a thicker barrier with more materials along with a greater cost. With noise, you do not want to spend one dollar more than you have to since you will never recover your noise costs. Barriers are a permanent build fix and no additional value is created by having a quiet room.

Eliminating the Need for Acoustic Caulk

Now that you have an understanding of noise and its movement through solids, we can re-examine the search term acoustic caulk. There should never be a need for any caulk at all. All edges should be straight and fit together with no gaps. Think of your room as a boat. It must be strong enough to withstand low frequency pressure waves along with middle and high frequency ray energy. Our room or boat must also not leak at all.

When you join two surface areas together there is no need for acoustic caulk or any other caulk type material. It is best when building acoustic structures to not use acoustic caulk but to use a liquid rubber. Liquid rubber comes in a spray that will fill and expand. It will also have a much greater density than caulk so we will be able to attenuate a much broader frequency range of noise.