Subwoofer Placement in Cars

Subwoofer placement in cars is limited to the trunk area. You do not have any rooms for a low-frequency generating device and its associated hardware anywhere else in the vehicle. The cabinet and amplifiers will take up considerable room and the trunk or rear area in an SUV will provide ample space for a cabinet, amplifier and driver assembly. It is not like locating a sub in a small room for two-channel audio where the location is defined by dimensions and room modes. We have to have space to place a cabinet that will weigh over 50 lbs. It’s like a piece of luggage fitting into your vehicle only the luggage never gets on a plane. Let’s examine the issues of placing any low-frequency source within a car.

Driver Size

The goal should be the speed of the driver, not the quantity of sound. You need to generate energy in short quick cycles so you can have a low-frequency time signature that can have a chance with competing with the speed of the middle and high-frequency drivers within the cab. To increase the driver speed in the subwoofer, stay with a smaller diameter driver. Look at 8″ to start. An 8″ driver will move 20% faster than a 10″ driver. We want fast transient responses from our drivers in a small room such as a car or SUV. Since most of the low-frequency energy generated by our subs will leave the car, a fast attack by the driver will produce tighter and cleaner “bass” sounds. Stay with a subwoofer manufacturer who designs and builds subwoofers for car audio. They test and design for car environments. Stay away from manufacturers who build for rooms and not cars. They are trying to expand their market share and will not devote the time and money to car audio research and development that a car audio manufacturer will. We have used JL Audio products for years and have always had good results in performance and sound quality and should be considered in any subwoofer placement in cars.

JL Audio : https://www.jlaudio.com/car-audio

Amplifier

Look for a driver that has an amplifier with a high damping factor. Getting the driver to work with the amplifier is a good start to achieving tight clean bass. There needs to be a scientific synergy between the driver and the amplifier. You can match the electrical performance parameters of the amplifier with the power requirements of the driver. You also need to make sure you do not overdrive the speaker with the amplifier. You need to keep the driver’s power requirements into balance with the amplifier output. Use a 2:1 ratio of power in the amplifier to the speaker’s maximum power handling capacity. If the driver has maximum handling of 200 watts, choose an amplifier that can produce 400 watts. This will allow enough headroom in the amplifier to produce enough power to compliment driver speed an accuracy.

Amplifier Class

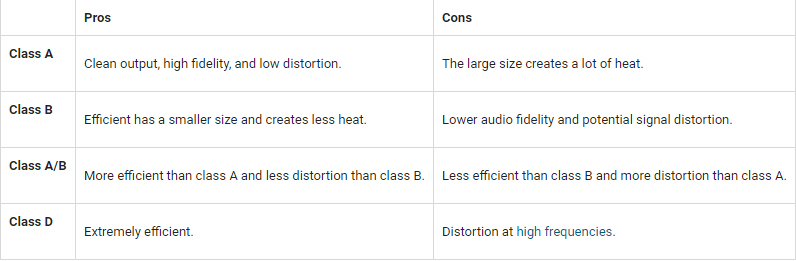

Subwoofer amplifiers come in four main types. We have class A, B, AB, and class D. Here is a chart showing the differences between the amplifiers in performance characteristics. Class A amps will produce the best sound quality but produce heat. Class B produces less heat and lower fidelity. I would stay away from class B amplifiers. Class A/B is a compromise between the quality and the heat. Class A/B amps produce class-A power at lower volumes but as you turn up the gain, the fidelity decreases. Class D amplifiers have the lowest heat issues of any amplifier but will distort at higher frequencies.

Comparison Chart of Amplifier Classes

Cabinet Design

Cabinet design has a large impact on sound quality. Sound from a speaker and a cabinet has three sound components. We have the sound of the driver itself. We have the sound of the cabinet and we have the sound of the trunk in which the cabinet is placed. The driver sound is the result of the materials used within the driver, the voice coil size and construction along with the basket or support structure that houses the driver. The cabinet has its own sound. You have the sound of the volume of the cabinet, you have the sound of the cabinet itself and you have the sound of the internal cabinet resonances. You can not control the driver’s construction but you can control the cabinet sound quality which is composed of internal cabinet resonances and cabinet wall vibrations. All of these issues must be addressed in any subwoofer placement in cars.

Cabinet is a Room

A speaker cabinet is like a small room. When you place energy within a room that does not fit, you have room distortion. We have the same room distortions inside our subwoofer cabinet. Those internal distortions must be measured and treated. Since our sub cabinet is small in volume we will have large amounts of distortions at lower frequencies within the cabinet. These distortions or resonances will be produced and will exit through the driver itself. They can be managed using our activated carbon technology which pound for pound is the most powerful of all the low-frequency technologies currently in the marketplace. Placing our carbon technology on the rear cabinet wall behind the driver will absorb that excessive back wave energy and allow for a tighter and cleaner sonic output. Controlling and reducing internal cabinet resonances will produce less distortion inside the cabinet that will exit through the driver.

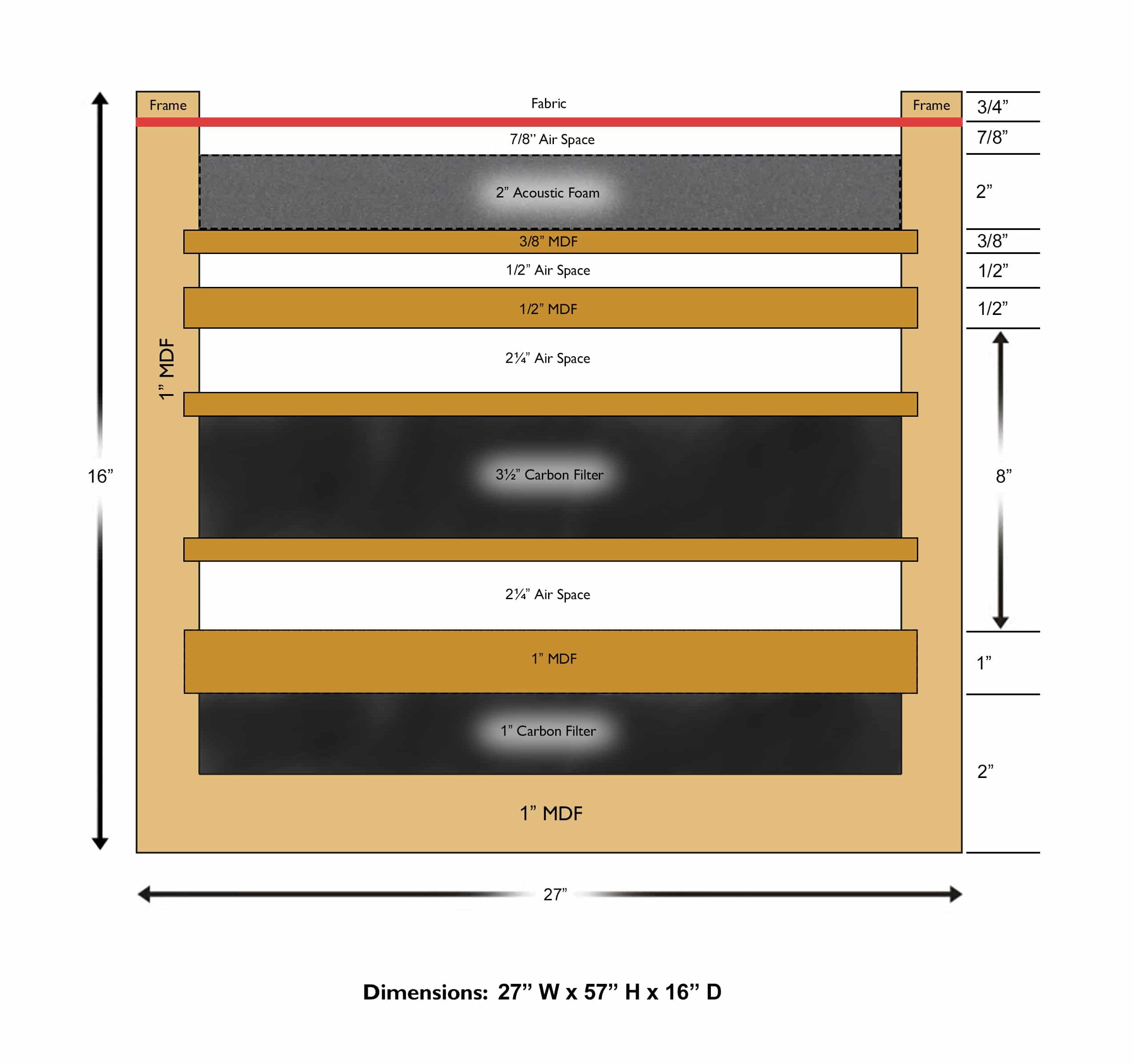

Cabinet Build Methodology

When building your speaker cabinet or buying one already built use a cabinet that has multiple layers to manage vibrations. Cabinet vibrations due to the excess energy inside the cabinet will distortion. You need to reduce the cabinet vibrations to reduce the distortion. If you use multiple layers of materials in the cabinet build, you can minimize the vibrations produced by the cabinet. Between each layer of the material in the cabinet use a mass loaded vinyl to sandwich between the higher density layers of MDF or plywood. Start with the densest layer of material inside the cabinet and work your way out towards the exterior of the cabinet with thinner and less dense layers always using the MLV between each layer. This process will reduce and minimize the cabinet vibrations that produce audible rates and levels of distortion.

Cabinet Support System

If you want to take the subwoofer cabinet installation for the subwoofer placement in cars, you isolate the subwoofer physically from the car body. Drill through your trunk and attach a steel support bracket to the frame and extend the bracket arms through the trunk. Install the subwoofer with rubber grommets to the subwoofer brackett that is attached to the frame. Use male and female connecting hardware so you can remove the subwoofer for maintenance. This is taking vibration isolation to another level. What people fail to realize is that sound quality no matter what the music or voice source and surrounding environment is the direct result of doing a lot of little things correctly but more importantly in the proper order. let’s use a speaker cabinet as our example.

Reducing the vibrations inherent in any speaker design is a paramount concern for the speaker designer. They know that vibrations produce sound. They only want their drivers to produce sound, not the cabinet. Removing the cabinet vibrations which by themselves are significant, damping the car body with mass loaded vinyl to minimize vibrations from movement vibrations, along with energy vibrations produced by our subwoofers is a step by step process. It’s an illustration of doing a lot of little things, which one by itself may not be a large audible issue; the combination of a lot of little things can produce audible distortion. It is another layer added to the overall noise levels in the chosen environment.

Death by a Thousand Cuts

It’s like death from a thousand cuts. We must reduce the layers of vibrational noise, we must reduce the layers of the room or car noise, and we must have the electronics to produce the distortion-free quality sound we are striving to achieve with all of this madness. Our electronics are up to this task. Our rooms and cars are not. We may have high-resolution digital domain electronics but you are then placing them in an analog room or car full of distortions. Every speaker you place in your car or room is screaming to leave. Listen to the cries.

About Us At Acoustic Fields: https://acousticfields.com/about/

We use broadband absorption in the two most critical frequency regions in small rooms. Our Diaphragmatic absorbers, ACDA series, have…

Interesting web site and provocative introduction. Please check your copy for typos, otherwise nicely presented. I would like to see…

There is no such thing as soundproof anything especially carpet. Low frequency noise transmission requires a permanent construction fix with…

Hello Dennis! Our neighbors put a Ice Bath in their garage which is right below our bedroom and the Low…