Soundproof Insulation

There is no such thing as soundproof insulation. There is no such thing as soundproof. Noise is never ‘proofed”. Noise is managed. Noise is a nuisance, unhealthy, and tiring. We must lower its impact on our lives through a process termed noise transmission reduction. There is not any soundproof insulation nor soundproof walls nor soundproof anything. There are no absolutes when it comes to noise. You never “proof”, you lower the noise levels to a level that is now not a nuisance. You lower the noise floor in a control room. You lower the noise floor in a bedroom. You lower the noise floor in a vocal room and in a professional mixing studio. You manage the noise. There is always some left no matter what barrier technology you use. Let’s discuss the barrier technology we will need to use in this process and how we go about building our noise barrier to reduce noise transmission into and out of our room.

Octave Bands

Noise – Frequency and Amplitude

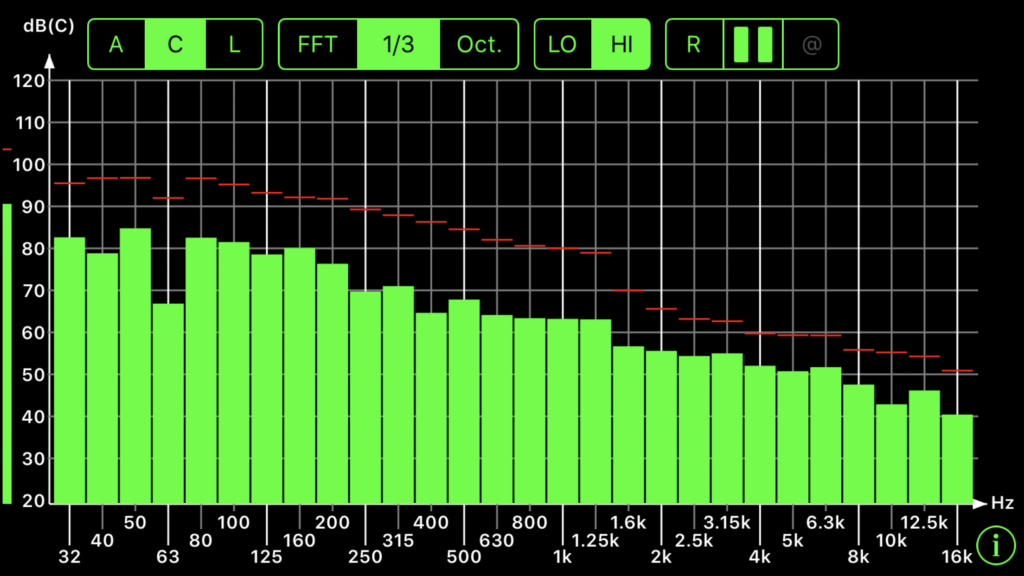

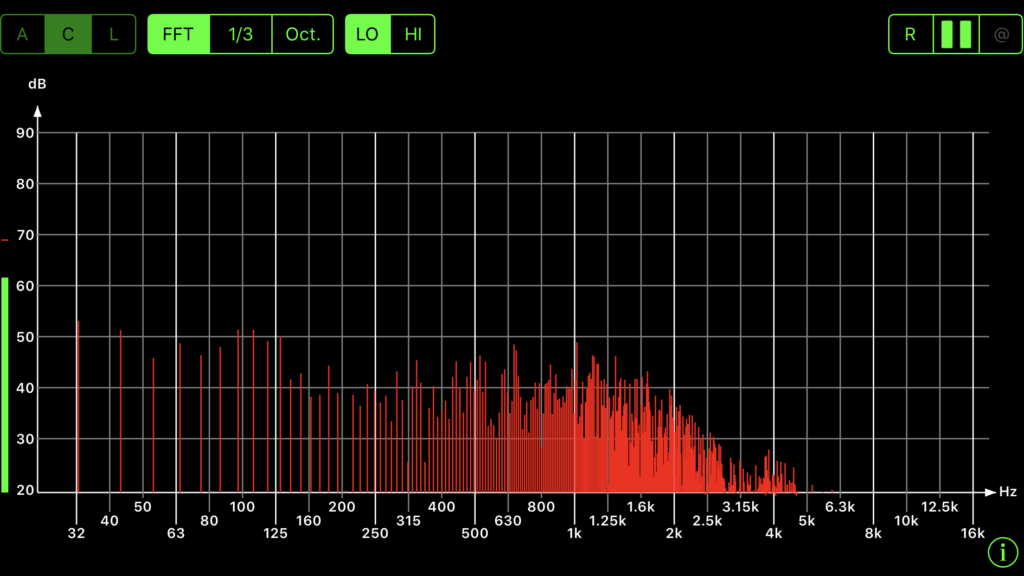

When we look at the noise, we must look at the frequency and amplitude of the noise. Noise has a frequency response just like our music and voice. It has a low-frequency start and can go all the way over 20 K Hz. We can measure it in real-time with a real-time analyzer. This software takes a real-time picture of the noise we are measuring. It will tell us in 1/3 octave bands the octave range of the noise we are measuring. We could have peaks in our response curve below 100 Hz. that can exceed + 10 dB – + 15 dB over baseline (flat). We always have peaks in our response curve with noise numbers. We can have peaks and troughs (dips) in the response curve with music and voice but not noise. It’s the peaks that produce the most energy. It is the peaks that have the fastest noise transmission through our walls. It is the peaks that we must design our barriers.

Noise Barrier : https://en.wikipedia.org/wiki/Noise_barrier

Noise: Two Parts

When we look at the noise, we look at all frequencies above 125 Hz. and all frequencies below 125 Hz. We do this two-part breakdown to determine what barrier technology we need to consider first. We know that noise frequencies below 125 Hz. take one type of barrier technology and those frequencies above 125 Hz. In general terms noise issues below 125 Hz. will require barrier technology that is multiple – layered, denser material types and different construction methodologies than frequencies above 125 Hz. The frequency is always an issue but so is the strength or amplitude of those frequencies. The strength of the frequencies below 125 Hz. will determine how many materials we will use and then how we assemble those materials that have different densities. There is no such thing as soundproof insulation or any other type of single material that will reduce the transmission of noise. Reducing the transmission of noise is all about vibration management

Frequencies

Vibrational Acoustics

When sound travels through the air, it becomes airborne energy. It has certain properties and characteristics that work in noise that is transmitted through the air. When that airborne energy strikes a solid surface it becomes a structural issue. When the airborne energy strikes a solid surface many different things occur. First, the frequency response changes when it strikes the solid surface. When it strikes a solid surface it turns into a vibrational response which is then transmitted through the solid surface. Different frequencies and different amplitudes produce different vibrational signatures. Our goal in any barrier design is to reduce the strength of that vibrational signature by making it go through different layers of materials that were chosen and constructed to deal with the airborne noise and thus the vibrational signature in our walls. Think about vibration reduction as the off-ramp on a mountain pass where trucks that lose their brakes go. The ramp is a 45-degree angle and the truck goes up the ramp. As it goes up the ramp with no brakes it bleeds energy off from the forward momentum using gravity. Hopefully, the truck stops before it hits the end where water or sand piles exist. The goal with any barrier technology is too reduce the amount of energy that strikes the wall just like slowing down our truck with no brakes.

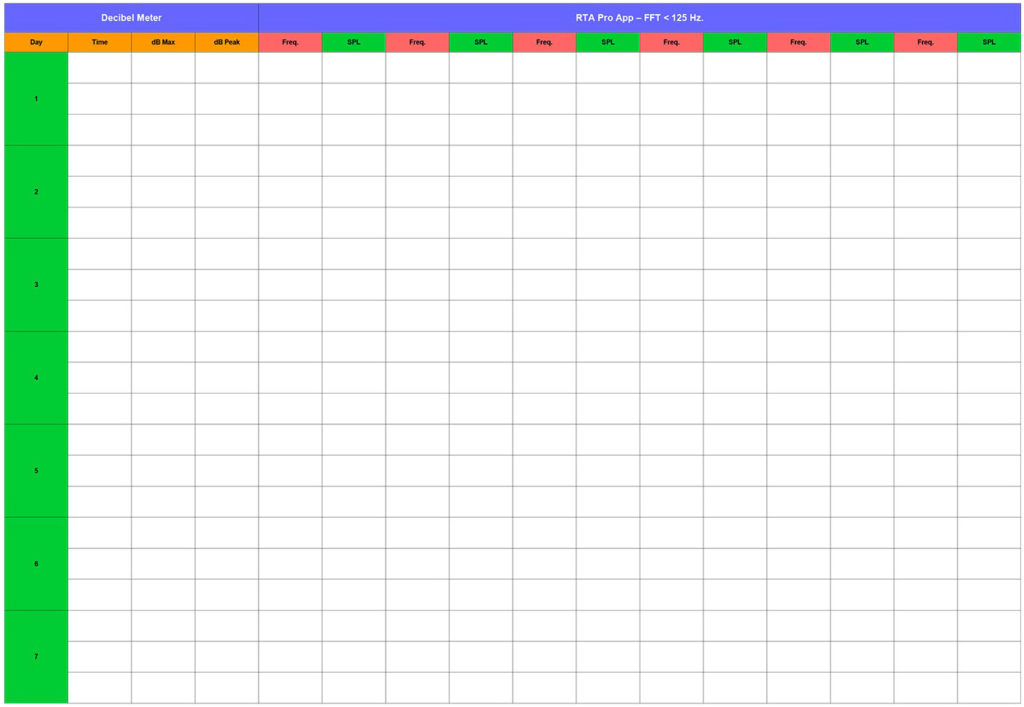

Data Recording Sheet for RTA Pro App

Seven Day Noise Numbers

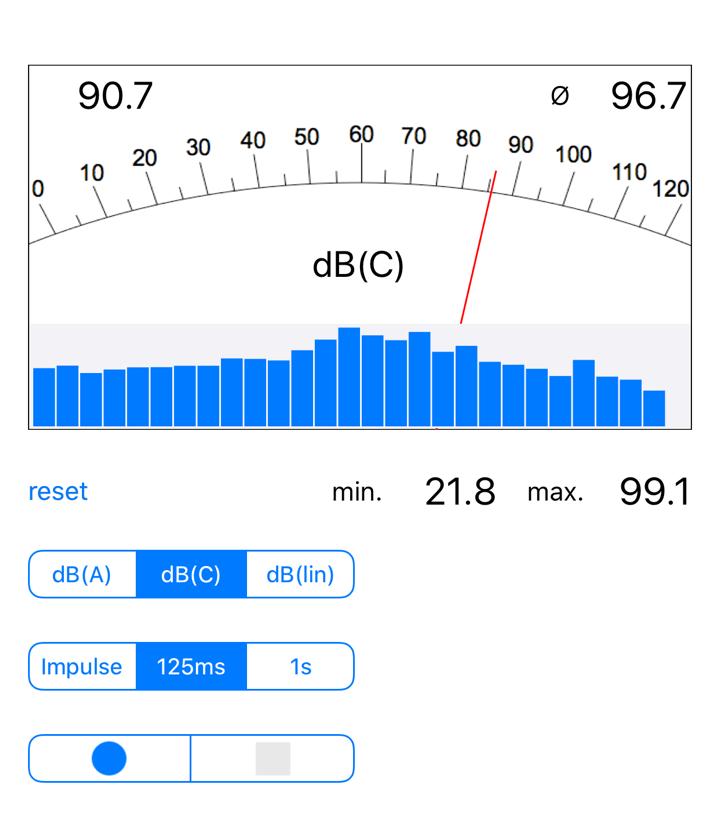

Before we assign any treatment types to our noise, we must first measure the noise over a seven day time period. We need seven days so we measure noise over a whole week. This will show patterns of noise frequencies and amplitudes at different times each day. We need to know each day what the noise is during the noisiest part of the day and the quietest part of the day, We need minimum and maximums for each day we will use the room. We need a minimum and maximum pressure level at the quietest part of the day which is usually in the early morning hours. We need a maximum noise frequency and amplitude over the noisiest part of the day. We need data because the barrier that we build will not be soundproof insulation. It will be a structure designed based upon noise measurements that are specific to your particular usage. We will measure frequency and amplitude using our phones as the measurement tool.

Design Process

We have three apps that we will use for our noise measurement process. We will use an RTA. We will use an FFT and a dB or sound pressure meter. the RTA is a real-time analyzer that takes a picture of our noise and divides our noise up into octaves. Every octave contains eight frequencies. It has a frequency range from 30 Hz. – 16,000 Hz. The FFT tells us the individual frequencies within each octave of the RTA. It breaks the eight frequencies in each octave down to individual frequencies that can be easily identified. The dB or sound pressure meter tells us the amplitude in the whole room. This is a good number to have. If we want to look at the amplitude (strength) of each frequency within each octave, we can look at the FFT it will show those frequency pressure levels in the left-hand margin. Once we have taken a picture of the room with our RTA, looked at each individual frequency that is causing the octave noise with our FFT, and measured the strength of each frequency, we are ready to record our minimums and maximums on our datasheet. All of these numbers can be obtained using an iPhone. You download the apps and follow our instructions on where to take your measurements and how to record them on the datasheet. You then send the datasheet to us for the analysis.

dB Reading

Data Analysis

We now take the minimums and maximums that we have recorded on our datasheet and look at the frequency and amplitude of each entry. Our goal is to design a barrier that will work for both the maximums and the minimums. If we design for the maximum pressure levels and focus on the frequencies of that noise frequency range, the minimum pressure levels will be covered. If we see that the largest amplitudes are at the lower frequency ranges below 100 Hz. we must use a different design than if the noise issues are above 100 Hz. Lower frequency noise such as garbage truck noise requires barrier technology that is thicker and denser than noise issues above 100 Hz. We must take into account the noise that is produced outside our rooms that enters our rooms and we must also take into account the energy or noise we produce inside our rooms that will leave our rooms and go to adjacent structures. Our barriers must be designed to work with noise that goes both ways.

Sound Barrier Technology: https://acousticfields.com/sound-barrier-technology/

Barrier Construction

Once we have determined the design we will use which is based upon the noise measurements we have taken, we can begin to assemble our materials. We use standard construction materials in all of our designs and standard construction methodologies. Any general contractor can follow our design and construction methodologies. What we have to realize is that any barrier technology we build must be a permanent build. There are no panels that you can hang on your walls or place within your room that will reduce noise transmission. This is sound-absorbing technology not barrier technology which is designed to reduce noise transmission. We must think of our room and its noise issues as a boat. We will place our boat into the water. If there are any leaks no matter how small the leaks are we must seal all of those areas. Sound is like water, it will find the smallest opening and go through that opening. The smallest opening in any barrier design structure can negate all of your measurements, design process, and construction methods.

Learn More About Us At Acoustic Fields: https://acousticfields.com/about/

In Summary

I hope today’s discussion on soundproof insulation helps solve the problem you are having. Please message me at info@acousticfields.com if you have any questions as I am always happy to help. If you want more to learn more about room acoustics please sign up for our free acoustic video training series and ebook. Upon sign up you will instantly have access to a series of videos and training to help improve the sound in your studio, listening room or home theatre.

Hello Dennis, Thank you for all the information you provide. It really helps to understand what we are up against when we make that desicion to build a home studio. My descision was made 4 years ago as part of a remodel. Then just as I am getting started an F4 tornado came through the day after Christmas in 2016. I was close enough to get some debris damage and lost windows etc.

Needless to say I am now finishing up the live room now that use to be A breezeway. It is now closed off. Blue Jean insulation, MLV and getting ready to install ISOMax clips for Hat channel. There is another part of this and that is the control room. An area that will be used only for mixing and listening. Planing on using Focal Twin 6 BE and a pair of JBL M2 speakers. Need to figure out what treatments are needed in both areas. The Live room and the control room.

J,

Fill out the information in this link: https://acousticfields.com/free-room-analysis/