Acoustic Foam

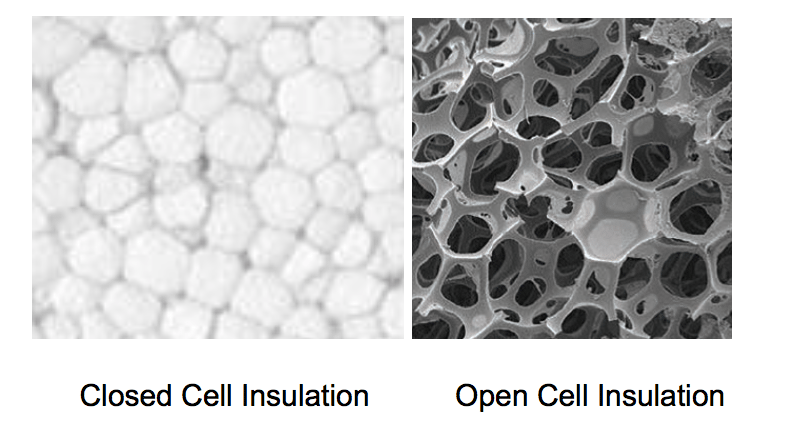

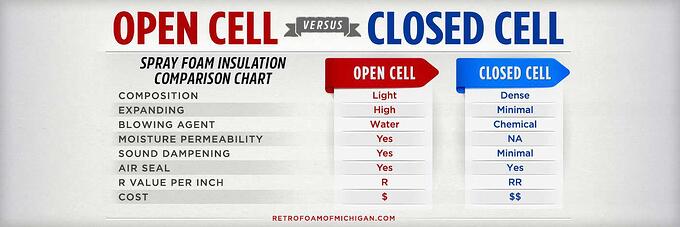

What is acoustic foam? Let’s first define what it is before we start the discussion of the best acoustic foam alternatives. Acoustic foam is the term used today for open-celled foam. There are two main types of foam. There are closed-cell foams and open-celled foams. Acoustic foam refers to the open-celled foam type. Closed-cell foam is the foam type that we use in couch cushions and our car seats. It is not designed to absorb the energy of any type. It is designed to support the weight. It is firm and dense and is designed to support the weight. It is designed to be a packing material for our products when we ship them. Do not be fooled by manufacturers who use closed-cell as the best acoustic foam alternative. Closed-cell foam is much cheaper to manufacture and we see many companies using that instead of the proper open-celled type.

Open Celled Foam

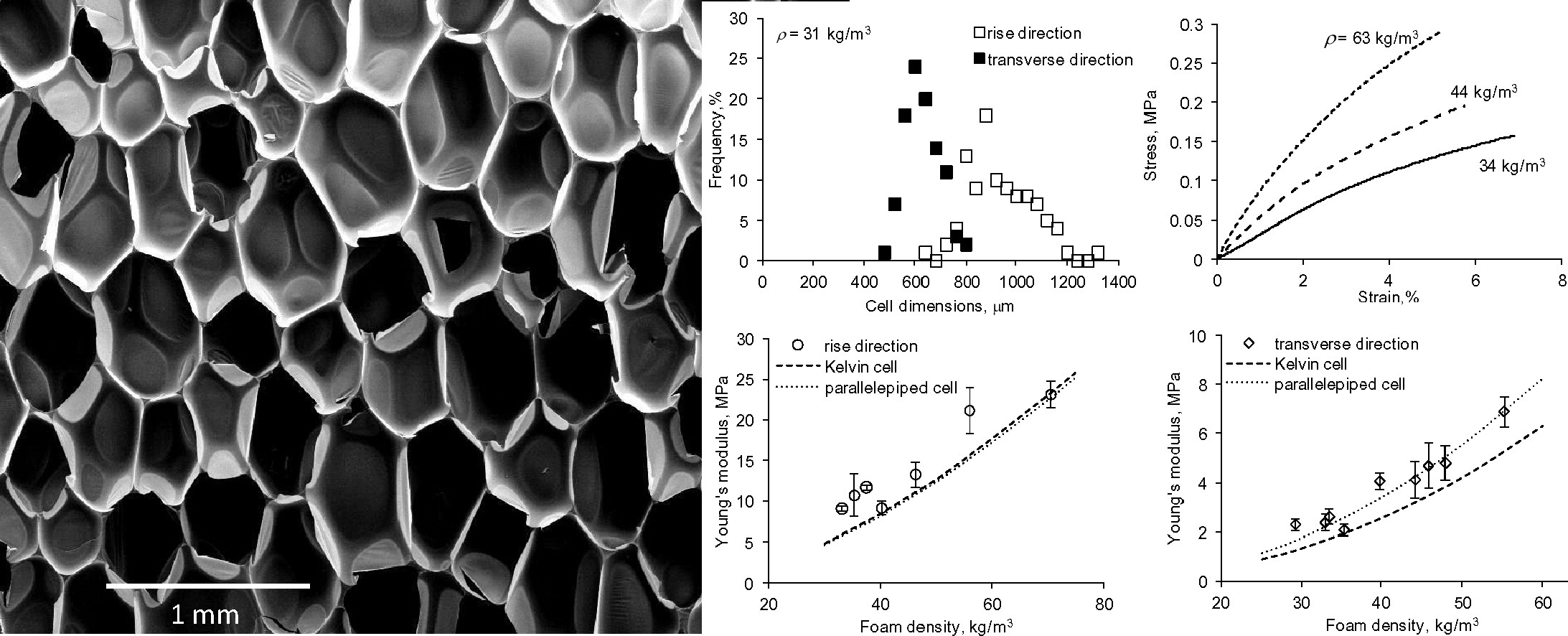

Open – celled foam is just what the name implies. The cells of the foam are open. They are open so airflow can enter the open cells and vibrate against the cell surfaces. This vibration or friction produces sound absorption. Friction produces heat which is an energy transformation. The change from airborne energy into each cell with the friction produced and the energy changes to heat produces the absorption we need. Every open-celled foam that is used for sound absorption has cells that are of different shapes and sizes. The larger the cells, the more air that can enter and the more sound absorption that occurs. Cell structure that is more uniform and consistent in their structures will produce a smoother rate and level of absorption. This is referred to in the industry as linearity.

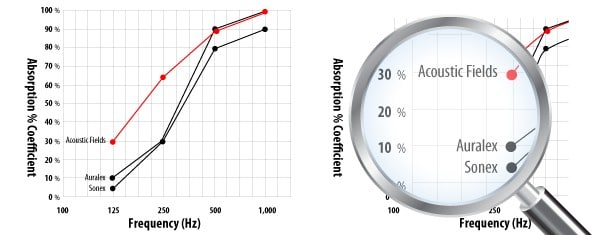

Rate and Level of Absorption

The best acoustic foam alternatives have a smooth rate of absorption and a low level of absorption. The rate of absorption is how much energy is absorbed in each octave band throughout the frequency range. The level of absorption is how low in frequency the foam will absorb down to. The thicker the foam the lower the level or frequency the foam will absorb at. In order to qualify as the best acoustic foam alternative, we need a design that has both a low level per thickness and a smooth rate of absorption. This is not easy to achieve. You must have cell structures that are uniform in size and connect with each other so there are no spaces between them. It is this connectivity and uniformity that produces a consistent and predictable rate and level of performance. With music and voice, it is all about the linearity of absorption. You want the product to produce a smooth rate no matter what frequency the foam starts working at.

Acoustic Fields Foam

Our foam technology took me 8 years to create at a cost of over 2 million dollars. I did not want just any foam. I wanted a design parameter that produced a product that worked only for music and voice. Most foams in the marketplace are what we call noise foams. Their goal if they have one is to produce a thickness of foam that absorbs as much energy as it can for every square foot of surface area. The reason we term these products noise foams is because with the noise you want to absorb as much as you can at the noise frequency and amplitude you are dealing with. This design parameter does not work for music and voice.

Music and Voice

Music and voice are different in their absorption requirements. With music and voice, you want to absorb just enough of the energy to reduce the negative effects of room sound. You do not want to absorb too much of an octave or frequency. This results in a too “dead” room. We have all been in those. The voice and music sound lifeless and unreal. Once you absorb energy it is lost forever. Once you absorb energy by converting it to heat through friction it is gone forever and you can not recover it. This is the reason some rooms sound “dead”. To achieve our design parameters our cell structures have to be uniform with the same size and depth. The density of the material needs to be rigid enough to support the cell structures uniformity but not so rigid that it will not allow for proper rates and levels of absorption. It must also be cost-effective to produce in large quantities.

Frequency Range

With voice and music, we measured many music venues. For the voice, we measured many corporate board rooms. Our design goals were focused on voice first. We calculated that if we could get voice correct using the proper rates and levels of absorption, music would also benefit. We noticed in measuring human voice in corporate board rooms that there was a deficiency in the energy that was from 125 Hz. – 250 Hz. Most rooms had “noise” foam in them when we measured them. They absorbed a lot of energy above the 250 Hz. frequency range but no much below that. This produced a rate of absorption that minimized the reflections from the walls and ceilings of the boardroom for those sitting close to the boss. However, as you moved down the long table, those at the second half of the table, the ones farthest away from the speaker could not hear well. We discovered that the frequency range from 125 Hz. – 250 Hz. was causing the issue.

Analysis

If you take a 125 Hz. wavelength and measure its length you will find it is 9′ long. If you measure the wavelength at 250 Hz. you will find it is 4.5′ long. We discovered that these lengths were getting distorted in the corporate board rooms. We were in rooms that were long and narrow with 8′ ceilings. It was the combination of all the room distances that were producing the distortion. The 125 Hz. wavelength did not fit into the rooms due to the 8′ ceiling height. The 125 Hz. wavelength did not fit in the width of the rooms since they were long and narrow. The 250 Hz. wavelength did not cause any issues since at 4.5′ it fit easily in the dimensions of the board rooms. It took the combination of the width, height, and length to reveal the distortion from 125 Hz. – 250 Hz.

Best Acoustic Foam Alternatives

After eight years and millions of dollars spent on research and development, we finally had the proper rates and levels of absorption for music and voice. We manufacture our foam technology in four thicknesses. We have 1/4″,1/2″, 1″, and 2″. The thicker the foam the lower the frequency it starts absorbing at. We make it in large sheets no matter what length or size you order that are 55″ x 75″ and can be cut to any size to fit your needs. We cut it will a waterjet machine to ensure that are edges are straight. No matter what your middle and high-frequency needs are we have the best acoustic foam alternatives regardless of who is saying what. No one has placed so much emphasis on the performance of an open-celled foam as we have at Acoustic Fields. It is used throughout the world and by our armed services.

Acoustic Fields Acoustic Foam: https://acousticfields.com/product/acoustic-foam/

About Us At Acoustic Fields: https://acousticfields.com/about/

I would like to purchase Acoustic Foam,in your store/company i would be happy if you can get back to me again with the prices and dimensions you having available in a moment,and also do you take all types of Credit Cards as your payment required?Kindly get back to me here so that we will work together as one panther. All the best and stay blessed.

L, You can purchase from web site. Go to Studio pro foam section.