Resonate absorbers are the most powerful of low-frequency absorption technologies. Pound for pound and square foot per square foot, resonant absorbers can not be matched for low-frequency absorption. They are sometimes called resonance absorbers. We are speaking about real low-frequency absorption which represents all frequencies below 100 Hz. Resonant absorbers are different than other absorbers. They work best in areas of high room sound pressure not high sound velocity areas like porous absorbers that handle middle and high frequencies. How does a resonant absorber work if it does not require airborne sound velocity flowing through it? We have updated this blog on 11/27/19 to reflect our current science and knowledge.

Vibrations & Sound Pressure

A resonant absorber is a vibrational system that “runs” on sound pressure. As vibrational science will tell us a resonant absorber is a mass vibrating against a spring. The mass is the cabinet and front wall or diaphragm. The spring is the air inside the cavity of the resonant absorber. If you change the vibrating mass and stiffness of the spring, you can control and tune the resonant absorber to the resonant frequency of choice. The internal mass or cabinet depth determines design frequency. The spring or internal air and cavity are used for achieving the rate of absorption above the unit’s designed for resonant frequency. There are three types of resonant absorbers: Helmholtz and Diaphragmatic and Membrane.

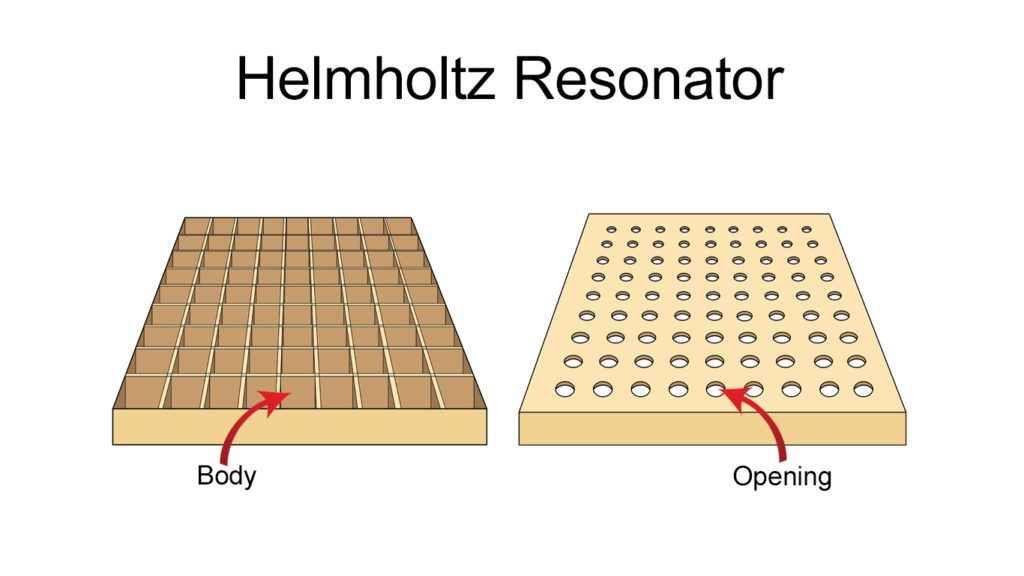

- A Helmoholtz Resonator design

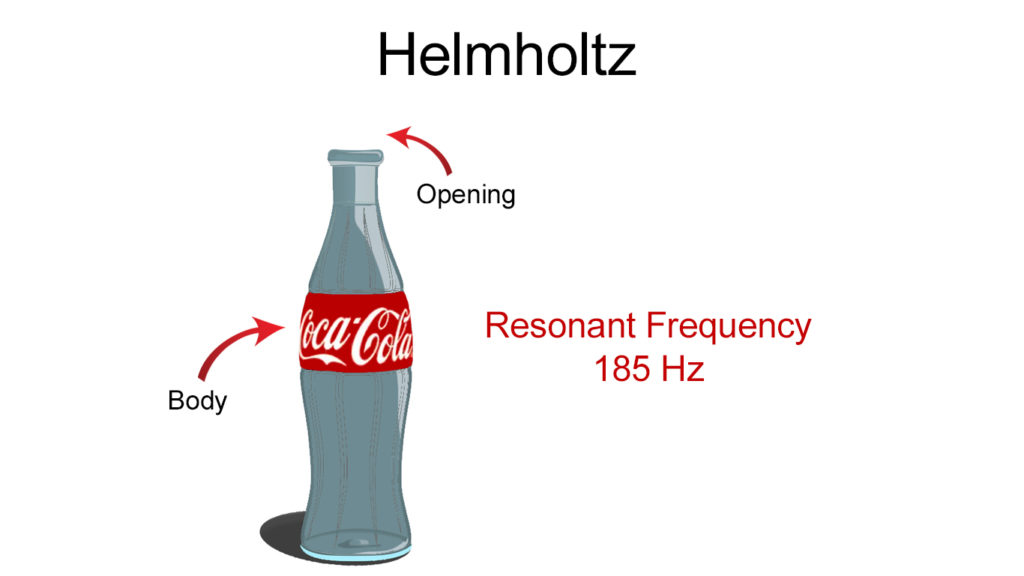

- A coke bottle is a Helmholtz Resonator

Helmholtz / Membrane

A Helm resonator is a box or tube with an opening or slot at its mouth. Air enters the slot which has a calculated width, length, and depth. The slot is attached to a cabinet or cylinder of different widths and depths. A glass coke bottle is a good example of a Helmholtz resonator. It is a resonant absorber or as some would term a resonance absorber. The frequency or resonance is determined by the slot dimensions along with the cabinet or cylinder depth. Helms are frequency specific and narrow frequency band coverage. A membrane absorber works similar to a diaphragmatic. It has a membrane than vibrates in sympathy to sound pressure. This vibrating membrane is attached to a cabinet which has a certain depth and fills material. A diaphragmatic absorber works similar to a membrane with more performance per square foot.

Helmholtz Resonant Absorber: https://en.wikipedia.org/wiki/Hermann_von_Helmholtz

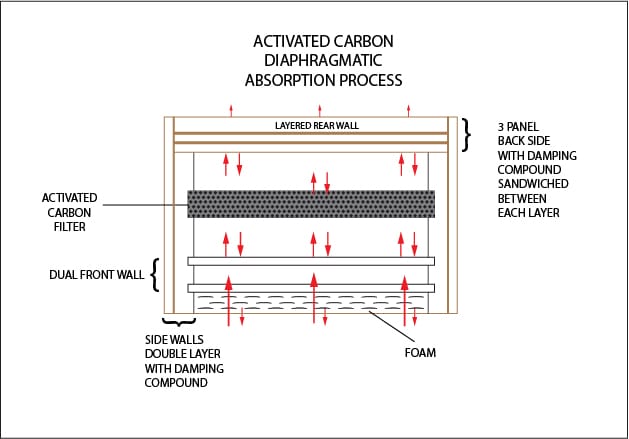

Internal Damping

To achieve losses inside a diaphragmatic absorber, damping is required. The damping must have air velocity to function. It must contain and suppress all internal cabinet dimensional resonances and also add to “mass vibrating against a spring” overall performance of the total unit. It is the internal cabinet fill material coupled with the vibrating membrane or front wall diaphragm, that add together to produce a synergy where a large amount of low-frequency absorption can be achieved in a small amount of space.

Sound Pressure

When sound pressure strikes the surface of a membrane or diaphragmatic absorber, it sets the membrane or diaphragm into motion. The membrane sympathetically vibrates or moves over a particular frequency response range which is determined by the mass (cabinet) and the air or “spring” inside the cabinet. This vibrational energy pushes air through the internal cabinet fill material and creates air velocity or molecular movement so the internal absorbing material can do its job.

Diaphragmatic Absorber

With a diaphragmatic absorber, you can manipulate the cabinet depth, diaphragm density, and internal cabinet fill material to produce a broadband low-frequency absorber or one that has more of a resonant peak and just focuses on specific frequencies. If you take the face or diaphragm of the unit and add an open-celled acoustic foam, you can achieve low, middle, and high-frequency absorption all in one unit. Diaphragmatic absorption rates are levels are much easier to design for then Helmholtz resonators.

In this video I explain more about the concept of diaphragmatic absorption and why it is so powerful.

Mass Equals Weight

With all of this low-frequency absorption and mass comes additional weight. A diaphragmatic absorber can easily weigh over 100 lbs. They can even approach weights of over 200 lbs. Performance does not come without sacrifice or cost. Mass or density is an integral part of the overall unit’s performance parameters and there is simply no substitute for mass when you are dealing with pressure area within your room from low-frequency resonances that approach and may exceed +20 dBA. It is like having cubic inches in an automobile for more torque. Larger cubic inch engines produce much more torque.

Diaphragmatic Absorbers: https://acousticfields.com/product-category/sound-absorption/acda-series/

Easy To Position

Diaphragmatic absorbers are easy to position. They work best in areas of high pressure within your room. These areas of high low-frequency pressure and low air velocity are usually found where two-room boundary surfaces meet. Wall to floor intersections along with ceiling to wall intersections are places where sound pressure is greatest. The corners of rooms where 3 room boundary surfaces intersect all also good places. Even though they are the most powerful, low frequency, sound-absorbing of all the technologies, you will still require numerous units to achieve manageable results.

So I hope that helps you. If you have any questions at any time I am always on hand to help answer them. Leave them in the comments section or email me at info@acousticfields.com. If you would like to learn more about room acoustics please sign up for my free videos and ebook by joining the mailing list here. I send room tuning tips and things for you to test in your room every Wednesday. They are easy to follow and really help you enjoy more of your music.

Thanks

Dennis

Hey guys, I just made a vocal booth in my closet and decked it out with fairly thick acoustic foam which is great but it’s very boomy, Iv been told to get bass traps but the problem is the booth is too small for a person let alone bass trap, I literally have to stand halfway out of the padded area and sing into a mic enclosed with acoustic foam. How else can I tame the low frequencies causing this boominess

Thankyou

Hi Andrew, Managing lower frequency energy in small rooms is all about size/usage/pressure. Fill out the information in this link. Lets take a look at all the necessary variables. https://acousticfields.com/free-room-analysis/

So diaphragmatic and membrane absorbers are both types of resonant absorbers? I thought membrane and resonance absorbers were different types? I also thought the main 3 were porous, membrane and resonance absorbers.. would be very grateful if you could shed some light on this for me.

Thanks,

C, There are three main types of resonant absorbers. We have a membrane, diaphragmatic, and Helmholtz. Membrane and diaphragmatic are similar in design but diaphragmatic uses higher densities in its design which allows it to go lower and absorb more energy. You can read about Helmholtz on the net.

Thanks for clearing that up! & great article, you have helped me to understand many aspects of acoustics which I have needed for my final university dissertation. Thank you sir.

Would like advice on adding a resonant absorbing system to the lid of a Randall 1/12 isolation cabinet used for recording. How to get a good recording sound, it currently has an odd boxy sound. I would like to also build some other isolation boxes with the sound quality of a Grossman Isolation cabinet. Can you help.

B, Sounds interesting. Send me pics of cabinets to info@acousticfields.com