Perforated panel absorbers are a type of hybrid absorber. They are a cross between a membrane absorber and a diaphragmatic absorber. They are probably equal in performance to a membrane absorber but not capable of going as low as a diaphragmatic absorber within the given panel depth requirements. By definition perforated panel absorbers have perforations on the front panel, that allow for air movement through them into the cabinet insides. A diaphragmatic absorber has a face panel that does not have any perforations and is solid. Even if the cabinet fill material is the same, the diaphragmatic absorber will always go lower than a perforated absorber. What is a PPA? We have updated this blog on 11/27/19 to reflect progress in our science.

PPA Construction

We take a box and build it out of plywood, MDF, or wood. The face of the panel has a certain thickness that can be increased or decreased to work into sympathy with the perforated holes. The perforated holes have a certain diameter and they act as miniature Helmholtz resonators. They are classified as a resonate absorber and each perforation or hole in the opening of each individual resonator directly behind the hole. If sound strikes the perforated panel in a perpendicular manner, then all the resonators are in phase and maximum absorption occurs. The sound that strikes the panel’s face at an angle will be reduced in sound absorption rate and level.

PPA Performance

To calculate the frequency of resonance of the cabinet, we need to look at the number of perforations or holes in the face as it relates to the total panel surface size. We also need to look at the diameter of the hole, the front panel thickness, and the total depth of the panel itself. If we increase hole perforation, percentage, and the depth of the cabinet absorber, we lower the cabinet’s resonant frequency in a linear manner. The opposite also occurs in the same linear fashion. A perforated cabinet with a depth of 5 5/8″, a .25% perforation, and a 1/8″ hole diameter, we can get down to 90 Hz.

Ceiling Perforated Absorber: https://acousticfields.com/product/ceiling-perforated-panel-cpp/

PPA Usage

Perforated absorbers have their places in sound absorption issues. They are lightweight and can perform better than most open-celled foams. Since they have a rigid box construction and internal cavity fill inside the box along with a perforated face that has holes designed with the correct diameter and number of holes to achieve the lower level of performance a PPA can achieve.

Diaphragmatic Absorbers

Diaphragmatic absorbers do not have holes or perforations in them. In fact, when most people see a diaphragmatic absorber they look for the holes for sound to enter through. When they do not see any, they wonder how it works. It works by first slowing down the lower frequency wave when it strikes the front wall. Then the wave enters the inside of the cabinet where there is an internal cabinet fill material. The internal cabinet fill material does two things. First, it absorbs the resonances that are inherent within the inside dimensions of the cabinet. Secondly, it works in harmony with the overall unit to produce the design resonant frequency of the cabinet.

Diaphragmatic Absorbers

Diaphragmatic absorbers are noted for their ability to go much lower than a perforated absorber. Both share the need to calculate the cabinet depth to produce the unit’s resonant frequency. However, the densities used in the build materials of diaphragmatic absorbers are much higher and with that increased density of materials come lower resonant frequencies.

Dia[phragmatic Absorbers: https://acousticfields.com/product-category/sound-absorption/acda-series/

Front Wall

A diaphragmatic absorber has a front wall that moves or “vibrates” in sympathy to sound pressure that is exerted upon it. When sound pressure energy strikes the front wall of a diaphragmatic absorber is moves in sympathy to the amount of pressure exerted upon it. this movement slows the pressure wave down. A diaphragmatic absorber is really a series of small barriers all assembled into a single box that is systematically designed to slow long wavelengths down. Once inside the cabinet, it is impacted by the internal cabinet fill and also the density of the cabinet itself.

Two Walls Better Than One

The cabinet, front wall, and fill material must be designed carefully to increase performance by lowering the start frequency of resonance of the unit. The front wall density is critical in the calculation. Along with the density of a single wall in the front of the unit, we have discovered that you can increase the overall unit’s performance by adding a second wall. Both walls must work together and move in sympathy with each other to produce the maximum amount of friction to slow lower frequency wavelengths down.

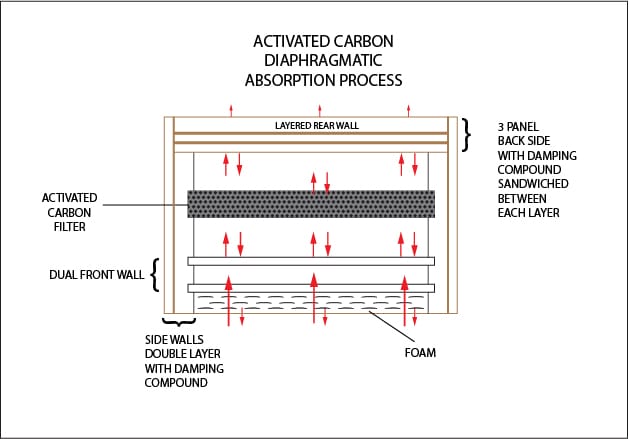

Rigid Cabinet Construction

To encourage both front walls to work together at their maximum capacity, our cabinet must be rigid and as inert as possible. To accomplish this, we borrow from speaker construction technology and use a cabinet that has multiple layers of materials with damping compound in between each layer to minimize vibrations and encourage rigidity. This increased rigidity in the cabinet over the front walls forces the front walls to move more than the cabinet. It is similar to a speaker, with the front wall acting as the speaker or diaphragm by moving. However, the front wall of a diaphragmatic absorber moves because of sound pressure, usually from a speaker on it and not from electricity moving through a coil.

Internal Cabinet Fill

The literature tells us to use fiberglass or some type of building insulation inside the absorber to absorb internal cabinet resonances and to impact overall unit performance. If you use those materials, you will get the performance the tables and charts indicate. However, if you pay more attention to the inside cabinet fill material and choose one that has a higher level of absorption than either fiberglass or building insulation, you can increase the unit’s performance by a larger factor. This is the reason for activated carbon inside our absorbers. We can lower the unit’s overall absorption capacity level and have a much greater impact on the rate of absorption. Our ACDA-12 diaphragmatic absorber is a case in point as it is the most powerful free standing bass absorber on the market.

Same Class – Different Performance

Perforated panel absorbers have holes in their face and diaphragmatic absorbers have a solid face. Diaphragmatic absorbers are good for going after frequencies below 90 Hz. Perforated absorbers are lighter in weight than diaphragmatic absorbers and are for absorbing in the low middle and higher critical band. Both need internal cabinet fill and benefit from material that has a high absorption rate and level other than that produced by mineral wool or building insulation.

In Summary

So I hope that helps you. If you have any questions at any time I am always on hand to help answer them. Leave them in the comments section or email me at info@acousticfields.com. If you would like to learn more about perforated panel absorbers please sign up for our free videos and ebook by joining the mailing list here. We send room tuning tips and things for you to test in your room every Wednesday. They are easy to follow and really help you enjoy more of your music.

Thanks

Dennis

We use broadband absorption in the two most critical frequency regions in small rooms. Our Diaphragmatic absorbers, ACDA series, have…

Interesting web site and provocative introduction. Please check your copy for typos, otherwise nicely presented. I would like to see…

There is no such thing as soundproof anything especially carpet. Low frequency noise transmission requires a permanent construction fix with…

Hello Dennis! Our neighbors put a Ice Bath in their garage which is right below our bedroom and the Low…