We have updated our designs for Diaphragmatic Absorber technology to improve performance. We have updated the information in this blog to reflect these design improvements on 11 / 3 / 19.

Low Frequency Absorption- Diaphragmatic Absorber Low Down

Absorbing low-frequency energy in our small rooms is no easy task. We are speaking of energy below 100 cycles. Many companies will claim to have a “bass trap” that does absorb energy in this frequency range, but most do not work. They may go down to say 40Hz. but that is their level of absorption. Its the rate of absorption above that level that indicates the product’s performance.

Diaphragmatic Absorption

The biggest issue with a freestanding, low- frequency, the absorber is mass or weight. Manufacturers design units that are lightweight to keep shipping and manufacturing costs down. Lightweight construction means lightweight or no performance. You cannot stop long, low frequency, waves with building insulation in a cardboard box. You can not stop it with a tube that is hollow and lightweight. Low-frequency energy requires mass. Its like cubic inches in an engine, there is simply no substitute when it comes to horsepower.

Definition: https://en.wikipedia.org/wiki/Bass_trap

Helmholtz Resonator

There are two real-world ways to absorb low-frequency energy. These are time tested and proven ways used for many years by studio building professionals. One is called a Helmholtz resonator. This type of absorber uses a tube that has a certain length, depending on the design frequency we are trying to absorb. A slit is placed in the tube top and air enters through it and causes the air inside the tube “vibrating” thus producing absorption at frequencies above the tube’s design frequency. A glass coke bottle is a type of Helmholtz resonator that has a resonant frequency of around 185 Hz. Frequencies above 185 cycles are absorbed and frequencies below are not.

Diaphragmatic Absorber

The second type of low-frequency absorber that professionals have used for years is the diaphragmatic absorber. A diaphragmatic absorber does not have an opening like the Helmholtz resonator does, it is a sealed unit. It uses the length or in this case depth dimensions along with other factors to determine the unit’s resonant frequency. A diaphragmatic absorber is similar to a speaker cabinet in design and construction. The front wall moves in sympathy to sound pressure and the cabinet stays inert.

Sealed Box- No Sound Holes

A diaphragmatic absorber is a sealed box that has walls that are very dense and a front wall that “moves” in response to low-frequency energy that strikes it. Once the energy strikes the front wall, it is slowed in speed and then enters the cabinet inside. The depth of the cabinet and the internal cabinet fill material, all contribute to the total performance of the unit. The deeper the cabinet, to a point, and the density of this cabinet, all contribute to the unit’s performance when chasing frequencies down into the 30 cycle range. Using our internal cabinet fill material which is our proprietary technology creates a lower pressure area inside the cabinet. A lower pressure area inside the cabinet causes the pressure wave to collapse.

In this video, our Chief Acoustic Engineer, Dennis Foley, explains the concept of diaphragmatic absorption in more detail.

Design Frequency

To build a diaphragmatic absorber, we must first decide what frequency or what frequencies we wish to absorb. As a general rule, the deeper the cabinet design, the lower the resonant frequency or sound-absorbing capacity of the unit. Let’s start with a lower design frequency of 40 Hz. and go from there. There are formulas we can use to determine cabinet depth which is synonymous with the resonant frequency. For the sake of this discussion, let’s choose a cabinet depth of 8″. This will be deep enough to achieve our 40 Hz. objective.

Build Size: 24″ W x 48″ H x 12″ D

Our cabinet needs to be 8″ deep to achieve 40 Hz. resonant frequency. Let’s just use this for example and illustration. Actual depth limits are found by using the cabinet density and front wall thickness. Our cabinet also needs to be very strong or what engineers term inert. Inert means that it does not move or vibrate. You see this term in speaker cabinet tests. They place an accelerometer on the cabinet, play a signal through the speakers, and measure the vibration of the cabinet structure. We need to adopt this same principle in our diaphragmatic cabinet build. We need to make the cabinet rigid, strong, and vibration-free. We want the front wall to move, not the cabinet.

[bctt tweet=”Want To Know How To Build A Diaphragmatic Absorber? #homestudio #acoustictreatments”]High Density Materials

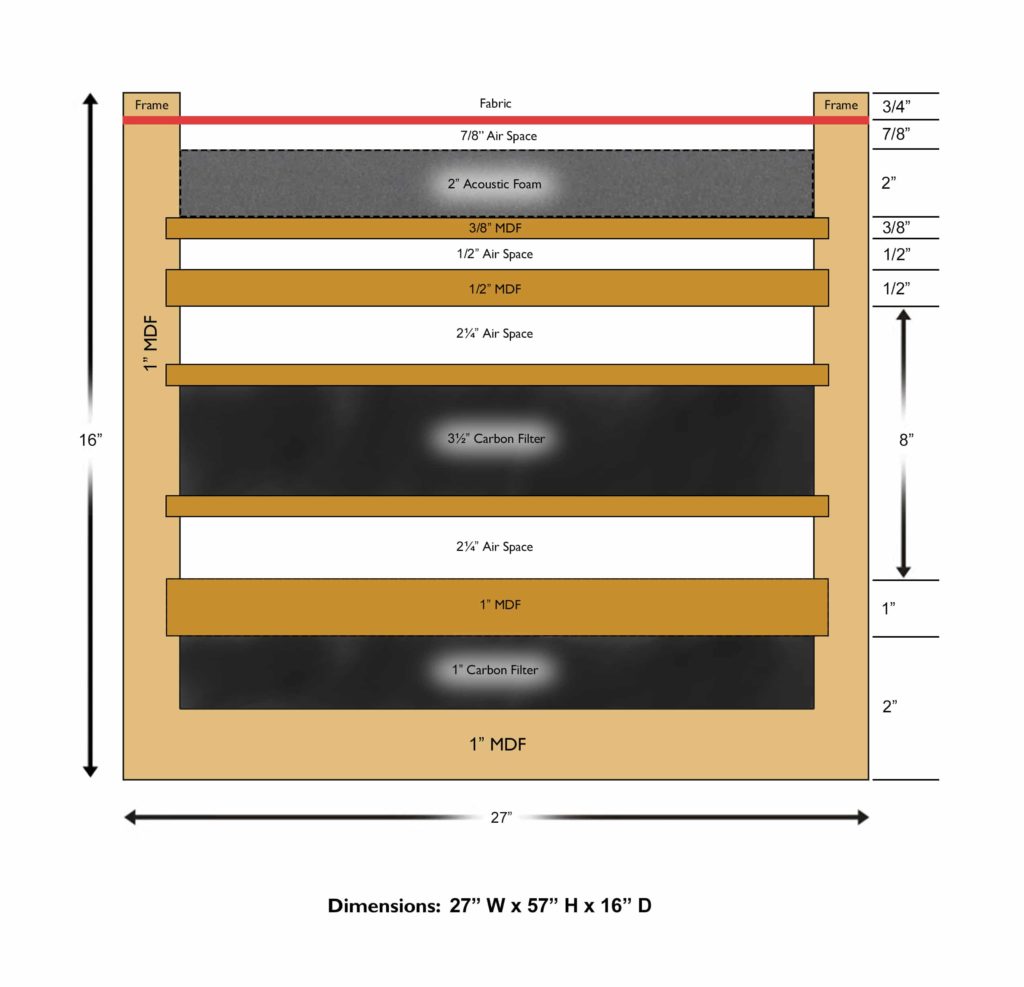

To achieve this inertness, we must use mass or materials that have a high density. Multiple density fiberboard (MDF) is a common material that has a high weight to area ratio. Choose the 1″ thick type. It is not available in all areas of the country. If you can not locate it in your area, you can use two 1/2″ pieces and glue them together. Better yet, place a layer of cork or some type of anti-vibration compound between each layer to assist the cabinet in minimizing vibrations. Let’s start with a height of 48″ and a width of 24″ with our predetermined 10″ depth.

Front Wall Diaphragm

The front wall or face of our unit performs the opposite function of our cabinet design parameters. We want the cabinet to be inert, but we want the front wall to move. Remember, it is the front wall’s duty to move in sympathy with the low-frequency energy that strikes it. This movement will help slow down the low frequency very long wavelengths that we are designing our unit to absorb before they enter the cabinet’s inside. We have taken this design parameter and expanded upon it. Our new designs use two front walls that are out of phase with each other.

Thinner Material

Our front wall should be of a thinner material than our 1″ sidewalls. Let’s use a 3/8″ thick piece for our front wall and a 1/2″ piece of MDF for the second wall. This will be thick enough to perform the function it is intended to do and also thin enough to move in response to low-frequency sound pressure. We must use caution in the method we use to mount the front wall to our unit. We want to mount it in a manner that will encourage it to “move”. The goal of the two front walls is to slow the energy down so it can enter the middle of the cabinet.

Front Wall Mounting System

When we mount the front walls in our unit, we should dado out for it to slide into the side walls. This will enable us to slide the front wall into the sidewall dado and keep a snug fit without the need to use any hardware. Remember, that this is a sealed unit with no openings to let energy in or out. Energy will strike the front walls, we have just installed, and then move through the front wall into the unit’s center cabinet fill. The rigid sidewalls (1″ MDF) will encourage the thinner front wall to move more than the rear or sidewall panels.

In this video Dennis explains the difference between membrane and diaphragmatic absorbers:

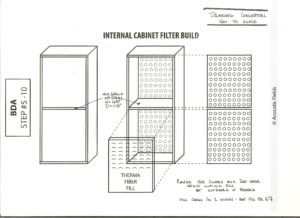

Internal Cabinet Fill Material

The internal cabinet fill material should be of a high enough density that it will absorb the resonances that occur within the cabinet itself and also add to the overall unit’s total absorption. We recommend that you use our foam https://acousticfields.com/product/acoustic-foam/or carbon technology. The carbon technology inside your BDA cabinet will increase the performance of each unit 100 %. You can obtain our proprietary carbon technology and foam from us directly. You can obtain our plans from: www.acousticfields.com/product/bda-broadband-diaphragmatic-absorber/

The Acoustic Fields DIY Broadband Diaphragmatic Absorber Plans

Diaphragmatic Horsepower

A diaphragmatic absorber will provide you with the mass and density you need to slow down low frequency energy using absorption. It takes mass to slow down the long wavelengths we are dealing with when it comes to low-frequency energy. It also takes an absorber that has the design parameters to deal with low-frequency energy. A diaphragmatic absorber can provide your room with the powerful techniques you will need to minimize the resonances you will encounter within your sound rooms.

If you would like a free analysis of your current room plans, please complete the form on this page https://acousticfields.com/free-room-analysis/ and we will run a free analysis for you. Alternatively if you want to learn more about this subject please sign up for our free room acoustic treatment videos and ebook which provide step by step instructions. Get instant access by signing up now.

Thanks

A good option for low frequency absorption is a mineral fibre wool used for fire insulation. It’s typically 3-4 times heavier per volume than the equivalent thermal insulation glass/mineral wool.

It’s costly but more effective.

Hi Simo,

Density is not the only variable that needs to be considered when you are dealing with the physics of low frequency absorption. You must design for frequency and magnitude (amount) of the energy you are trying to absorb. You must also design for rate and level. Achieving a resonant frequency of 40 Hz. (level) in a box is not difficult. Achieving a proper rate of absorption above 40 Hz. is the most challenging part. Density will only take you so far.

I read the answer you give to Simo Grönlund, you are trying to say that It works better with 40kg/m3 than 100? or just that 100 kg/m3 it’s not necesary?

Sorry if my english is not the best.

Diego – Uruguay

Hi Diego, We use a volume measurement here in the states, termed cubic foot. In metric, it would be a cube with sides of 304 mm. The metric system uses cubic meters, so we will have to translate. Use something that has around 2 lbs / cu.ft. If we take that x 27, you would have some minimums to go by in a cubic meter. With this system, which is a perforated absorber within a diaphragmatic absorber, we must have at a minimum, a fill that controls the resonances inside the perforated absorber itself and the internal diaphragmatic chamber. Carbon does this better by a factor of 30 % over any other fills. I know because I had to try 12 different ones before I found carbon.

I have a tangential problem you may be able to help explain. It may be converse to the absorption mechanism you have discussed so well. It concerns the impact of low frequency sound causing vibration within a closed space when little energy is absorbed by the box or the material contained within. I had a plexi bonnet on an MDF base 100 ft from a professional sound system used by a DJ during a party. My guess is the bass component of the music caused the plexi case to vibrate vigorously. A brass urn within the case also vibrated sufficiently over three hours of music to make the urn shimmy 1.5 inches towards the middle of the case. Can you explain the dynamic? I didn’t expect movement to be generated by sound over a large distance great enough to move a 1 lb. brass object. I’d like to understand what happened and what I can do in the future to prevent a recurrence. Any help with this would be appreciated.

Hi Steve, Low frequency less than 100 Hz. strikes the structure and causes the structure and the urn to start moving in sympathy. The structure vibrates, the urn vibrates, both from air born and vibration energy. You must reduce amplitude or strength of the wave to be lower than the resonant frequency of the structure and the urn. Is someone ashes in the urn? I hope they liked bass when they were living.

Hello,

thank you so much for amazing info!

What is effective frequency range of the absorber described above?

I read somewhere that for standard limp mass absorbers it is +/- half an octave.

So, If it is designed to work for 40 cycles, the effective range is from 20-60 hz?

Is it correct?

Hi Daniel, You can find the independent Riverbank Labs test data on our home page in the what makes us special section. Our ACDA -10 unit is a broadband absorber that begins at 30 Hz. and goes through 200 Hz. The ACDA-12 starts at 30 Hz. and goes through 50 Hz.

You make the point in the description above that the front wall should be allowed to move:

“We must use caution in the method we use to mount the front wall to our unit. We want to mount it in a manner that will encourage it to “move”.”

Given this requirement, should the front wall be glued to the carcase (or slipped in and left floating)? I’ve bought the BDA plans and it’s not obvious to me what the right approach should be. One would think a snug, slip-fit should still provide a seal to the cabinet but allow the front panel to move more in response to sound pressure exciting it.

Hi Chris, Pressure fit the front walls into the dados. Make sure they are snug in the dado. No need to glue.

I’m helping to design a 350 person hall for amplified music and am looking for ways to reduce the reverb time of bass frequencies while preserving somewhat “normal” venue aesthetics. Can diaphragmatic absorbers be inset in the wall or span a corner?

J, Perhaps, if low frequencies are the issue. My best guess is that your issues are middle and high frequency reflections from the walls and ceiling. These can be managed with surface treatments. Any low frequency issues can be managed by placing the low frequency absorption technology as close to the source as possible. If you have a stage, that would be a good place to start. Fill out the information in this link and include photos of all surface areas. Lets take a look. https://acousticfields.com/free-room-analysis

Would this absorb outside sound? Like bass or 60-120hz noise coming from outside a room?

Our ACDA units are sound absorption technologies to manage the energy within your room. They will absorb excess energy that is already within the room. They are not designed to keep energy from entering the room.

Hallo dear Dennis. I am interested if whit absorber I can lower modal ferq. The freq. I am asking you about are:

35.29 Hz C1# 1-0-0 ax

70.58 Hz C2# 2-0-0 ax

Also, I wont to know if the absorber that is projected on 35.29Hz works on 70.58Hz too or should I have to make all separately ??

Thank you forr readyng and your answer in advance.

Best regards, Lepi

Hi Lepi,

You will need our ACDA-12 technology which absorbs from 30 – 50 Hz. It will absorb 2 dB / unit.

Hi Dennis, I have recently moved house, and the RT60 of anything below 300Hz is very difficult to work with.

I had an idea to use an array of pipes, tuned to the problem frequencies, suspended by elastic strings to absorb the excitement of the pipes.

I need something cheap and simple to build, but the information on helmholtz type traps is lacking. Do you think that this would work? For specific frequencies as opposed to broadband absorption, could you suggest a better method?

Hi Chris,

You need broadband absorption for this issue. Fill out the information in this link: https://acousticfields.com/free-room-analysis/

Hi,

I made 6 closed cabinets 180cmx120x15 MDF with a thin hardboard front. My rockwool was almost finished at the end so the last cab only has 2 slabs of 120x60x10 cm rockwool in it. Will this cab still be effective just at a little higher freq then the others, or is it useless and should I open it up again. Thanks in advance for the info!

J, What is the frequency response of the unit you built?

Hi Dennis,

I just bought your DIY plans for building the Diaphragmatic Bass trap. My room resonances are at 52Hz and 100Hz. How can I calculate the depth of the cabinet so that I can cater for both these frequencies?

Please note, I am based out of India, and won’t have access to your products, so will be using equivalent materials of foam based on specifications.

Thanks

A, The BDA unit is a broadband absorber from 30 – 300 Hz.

Hey Dennis! About painting the absorber, Is there some specific kind of paint I want to use or would anything do?

A, Paint choice has no impact on performance.

Dennis, Thanks for all the useful info on your website. I am building 5 of the ACDA-12s to fit under my diffusers in the front of the room. The dimensions are 50″ wide x 16″ high x 18″ deep, so they can hold up 2 of my QRD 23 diffusers. So your DIY plans show 8″ to the back wall from the front resonator. On this page, you say that the deeper the trap, the lower the frequency it can handle, so as the unit will be 18″ deep anyway, should I move the back wall back a few inches? The back wall will be 3 layers of 1″ MDF (the rest of the unit is 2 layers of 1″ MDF. thanks

R, What are the frequencies of concern for your front wall?

Dennis, The bumps and nulls I have range from about 30hz to 60z. I also have a fair amount of overhang in the 20hz – 40hz region. To me, the overhang (which I assume is related to the bumps) is more noticeable than the dips

R, You have to treat the fundamentals first. You must treat the area of your room that is causing the frequency and amplitude issues. Front and rear walls have different issues than side walls and floor to ceiling surfaces.

Hello,

Does the unit need to be mounted to the walls of the room or far from the walls?

can it be placed to the ground, ceiling or floating on the wall?

Is there any preferred direction it should be positioned?

thanks, Tomer.

T, Unit weighs 230 lbs. It must sit on the floor. The foam face must face into the room.

Hi I am living in a place where there is loud low frequency noise from fighter aircraft. I am planning to do another layer of decoupled wall and ceiling to isolate the noise. Will his be enough or you think the Diaphragmatic Absorber will help a lot from situation like this? If the noise is outside, will placing the diaphragmatic absorber inside the room help?

T, A diaphragmatic absorber absorbs energy within a room. It will not keep noise out of your room. Decoupling a wall against aircraft noise will not work. You must first measure the noise and then design the proper barrier.

Trying to find a material(or combination of materials) (along with foam) to maximise sound proofing inside of a sealed case for a DSLR camera that is too noisy – any ideas? the noise needed to be removed is that from the shutter, could this be absorbed or reflected internally… by cork or MDF layers?

A, We can not assist you with this project.

hello dennis

I bought DIY Bass Absorber – BDA (Broadband Diaphragmatic Absorber) Build Plans several years ago, but I see that the designs have changed in depth (14 “vs. 16”) and thickness (3/8 “+1/4” vs. 1 / 2 “+3/8”) Where can I get the new designs?

C, The depth has only increased if units are on casters. use 3/8″ for first front wall diaphragm and 1/2″ for second front wall.

Hi Dennis,

concerning the BDA DIY, is there a substitute wood you could recommend of for the cabinet (instead of alder and basswood)?

thanks

A, Use MDF as the drawings indicate. You need the density of MDF for performance.

Hi,

I have an issue with frequencies below 20Hz from specific directions outside the house. What would your recommendation be? Can I build barriers that can block or attenuate these signals e.g. the MDF?

A barrier that can mitigate 20 hz. energy would require extensive design work, be 24 – 36″ deep, and cost a small fortune.