Acoustic Design Project

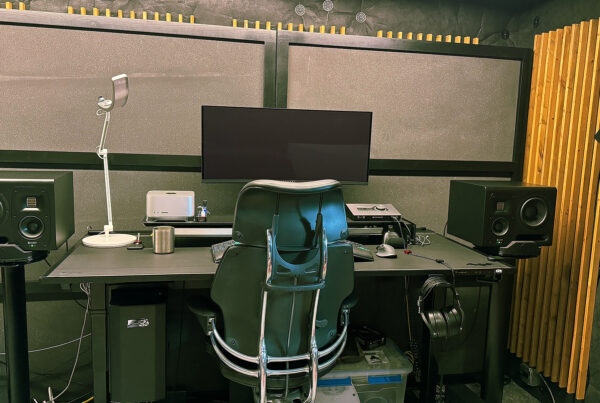

Home Cinema

If you have an existing home theater, you do not have much available space for treatment. We notice in most home theaters that acoustical treatment is the last thing people think about when it should be the first. Treating low, middle, and high frequency issues within small rooms is all about placing enough surface area coverage on each wall to treat the issues the room dimensions and usage present. Our module series of absorption and diffusion technologies, will give you the treatment performance your room requires in a smaller module package.

Treating acoustic frequency issues within small rooms is all about two main variables. The first is the rate and level of absorption performance within the treatment type for low, middle, and high frequencies along with the proper square footage of treatment surface area. A room is a closed system. Enough energy is contained within to measure and understand the distortions produced by the box. The issues within our box are predictable and consistent in their frequency, amount ( amplitude) and physical position within the box. Once you have determined the frequency, amplitude, and location within the room, you then apply the correct rate and level along with enough surface area coverage to achieve your absorption goals for the room usage.

When you build a new room from design, you can minimize many room distortions. This distortion lowering from the beginning of the acoustical process allows the treatment used within the room to work better and more efficiently. It is similar to the pressure level one prefers to listen to music at. That level is usually determined where the system and the room sound best working together and not against each other from the start. All rooms need low, middle, and high frequency management. Based upon our 14 years of doing this, we have realized that low frequency management and diffusion are the two most costly treatment options. Middle and high frequency absorption is usually one half of low frequency costs.

The Most Powerful Absorption Technology

With existing rooms, we have a closed system. We know the size and volume and like it or not this is what we have to work with. Moving forward, we must calculate the amount of low, middle and high frequency absorption using our carbon and foam technology. Our carbon based technology is for low frequencies less than 100 hz. Our foam is for frequencies from 125 hz. – 6,300. This is by design since this is the frequency response mix engineers work within producing our music. We use our ACDA-10 modules for this project along with our Foam Frame Panels. Since it was an existing room our space availability was what it was. The client came to us because he had treated his room with products from GIK Acoustics.

He was not happy with the low end of his theater. Theaters usually produce more low end than the room can handle so there are always lower frequency modal issues. He was also not happy with the middle ranges. He said they were lifeless, without conveying any feeling. Our carbon technology is the most powerful per square foot of any technology currently within the marketplace. It has the same rate of absorption by design as our foam technology. The middle and high frequency issues needed to be managed in a cost effective framework if you will. Our foam technology took 8 years to develop at a cost of over 2 M. We took what we had to work with and filled in as many spots as we could using an existing budget and space availability.

Module Products

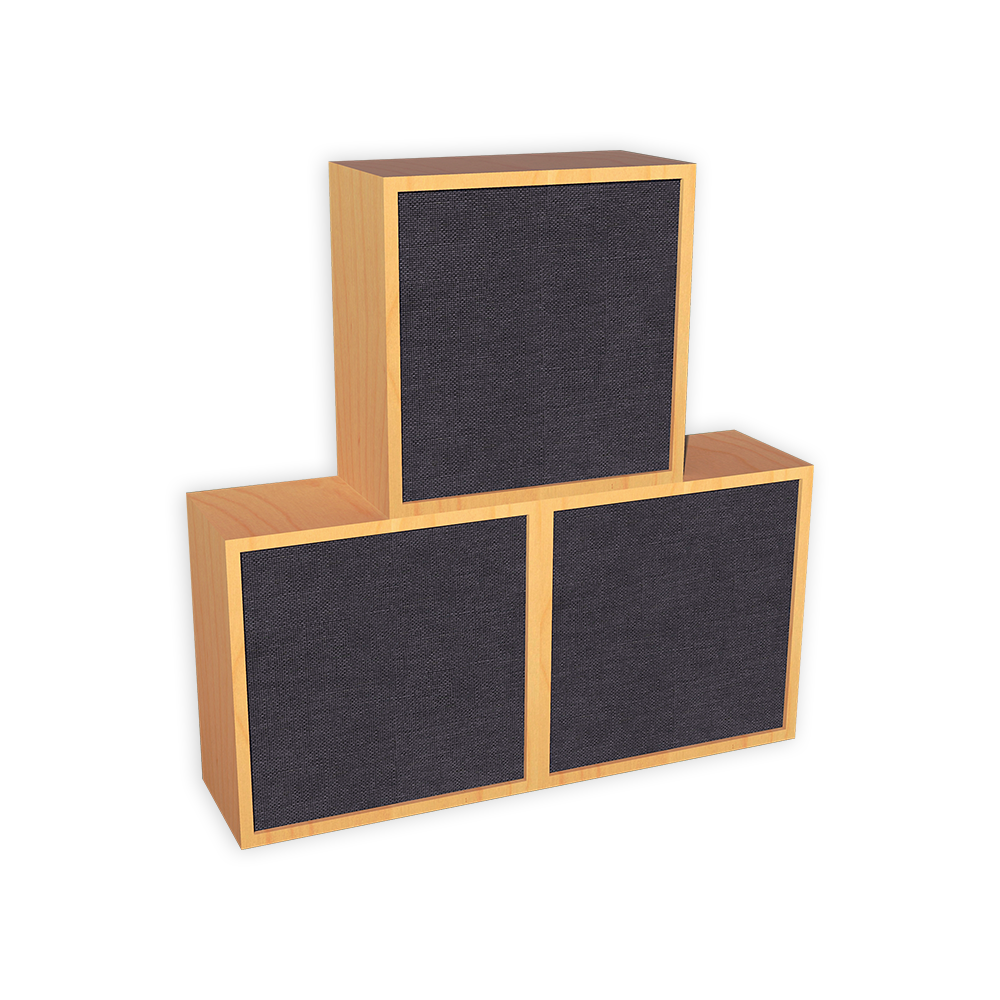

ACDA-10 M

The ACDA -10 modules are our highest performing product. They follow the absorption coefficients of the ACDA-10 with a stronger emphasis on the 60 – 80 Hz. range. The full range absorption for each module is 30 Hz. – 6,500 Hz.

This increased performance comes in a module that is 24″ x 24″ x 12″ and weighs 70 lbs. Modules are stackable and the number and surface area coverage can be fined tuned in your room size/volume/usage.

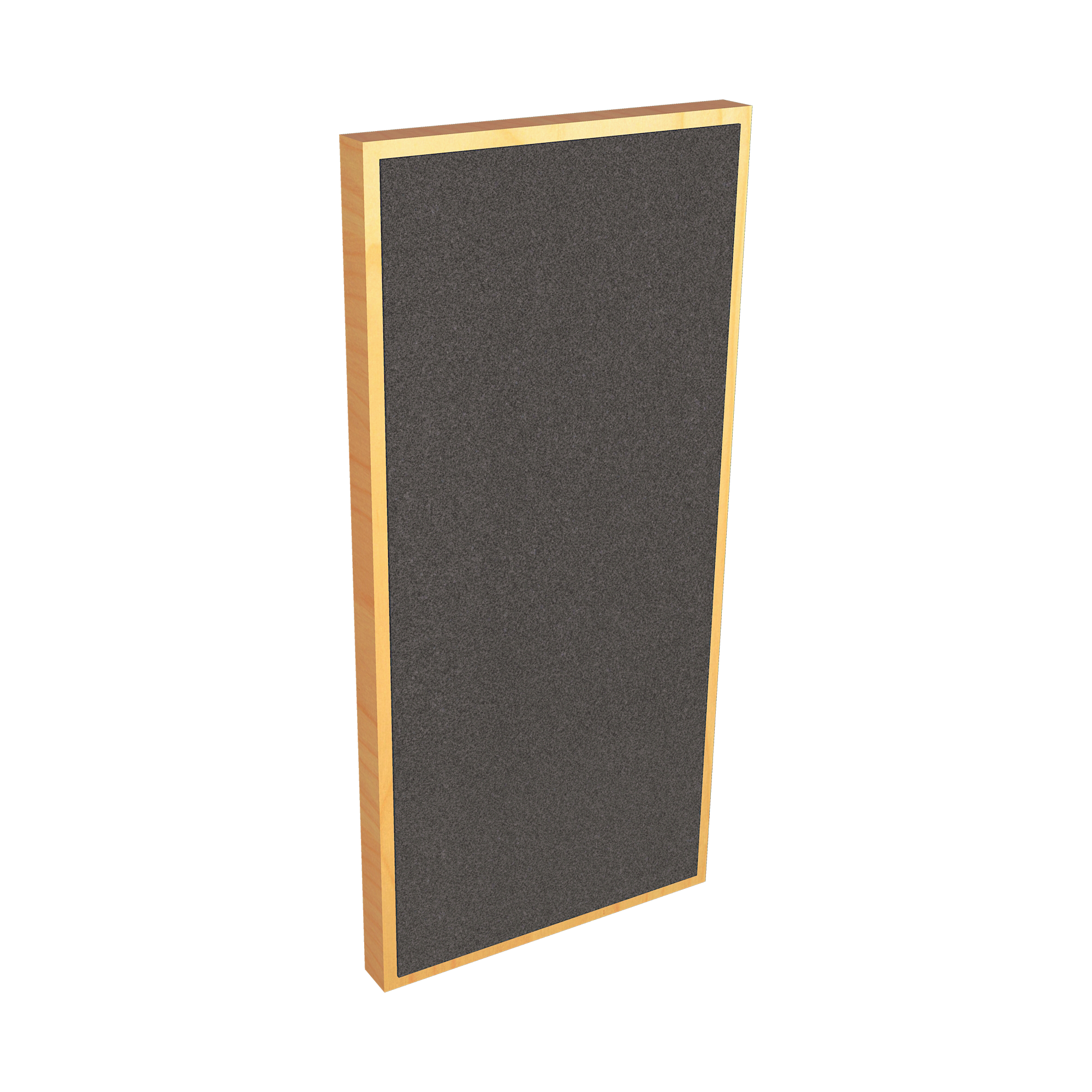

Foam Frame Panel

The most economical way to install our foam technology on your walls or ceiling is to use our foam and the mounts. This allows for airflow on both sides as the mount pushes the foam 2″ away from the surface to allow for air floor. Foam and mounts are designed to work together. Wood frame can be painted any color. Foam is grey only.

ACDA-12 M

Each ACDA-12 module unit is a sealed cabinet. They are 48″ w x 30″ h x 12″ d and are the bottom row that supports the ACDA-10 units. They can be painted or custom veneered per your request. Each unit weighs 150 lbs. and provides a solid and sturdy base for the stacking of the ACDA-10 modules or the QD-13 modules. Up to 3 rows of ACDA – 10 units can be stacked upon the ACDA-12 modules. They are positioned along the floor of all 4 walls in any critical listening environment.

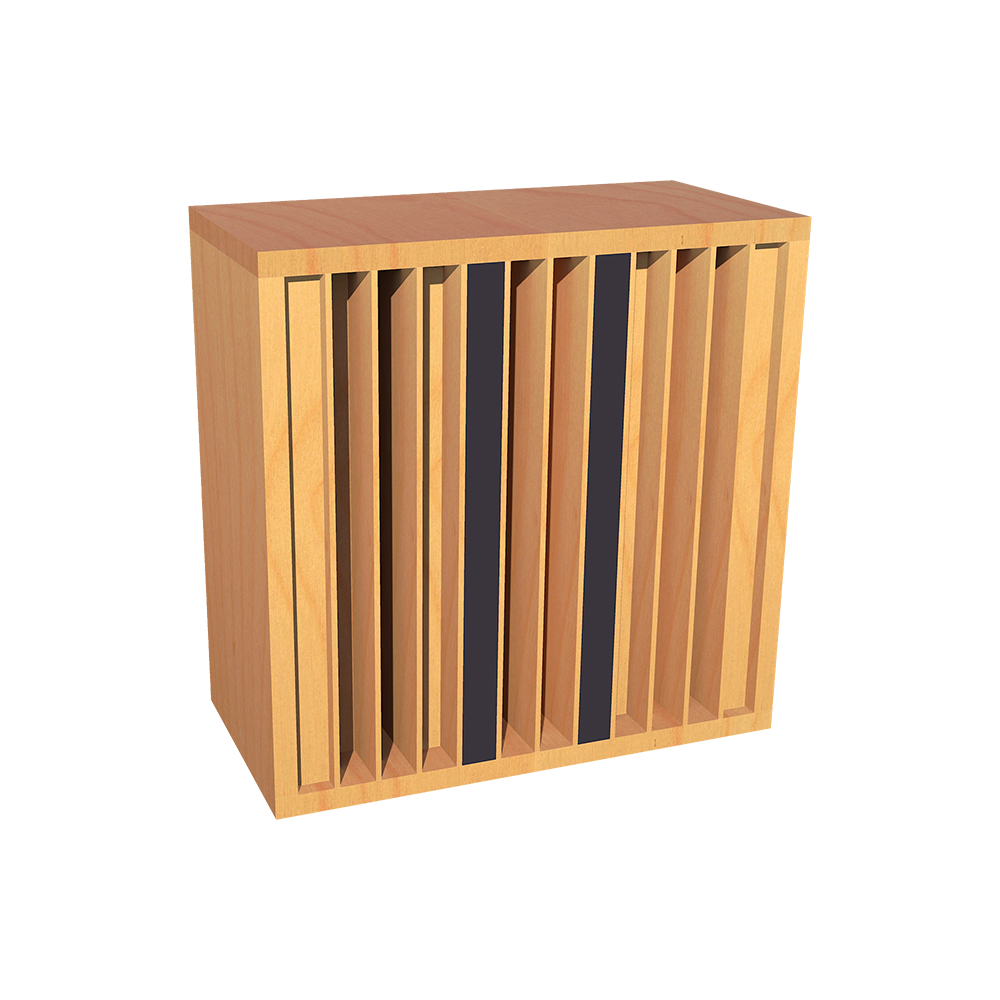

QDA-13 M

It is important to have both frequency-specific and broadband low-frequency absorption on all wall surfaces. Our QDA M-13 has our carbon technology installed inside the diffuser itself. You achieve the same performance as our ACDA-10M and the power of prime number 13 diffusion all in our 24″ x 24′ x 12″ d module that you can stack and create both one dimension and two dimension diffusion.

Do you want to solve your room acoustic problems?

There’s no one size fits all when it comes to room acoustics.

Get your FREE personal room acoustics analysis by chief acoustics engineer Dennis Foley.