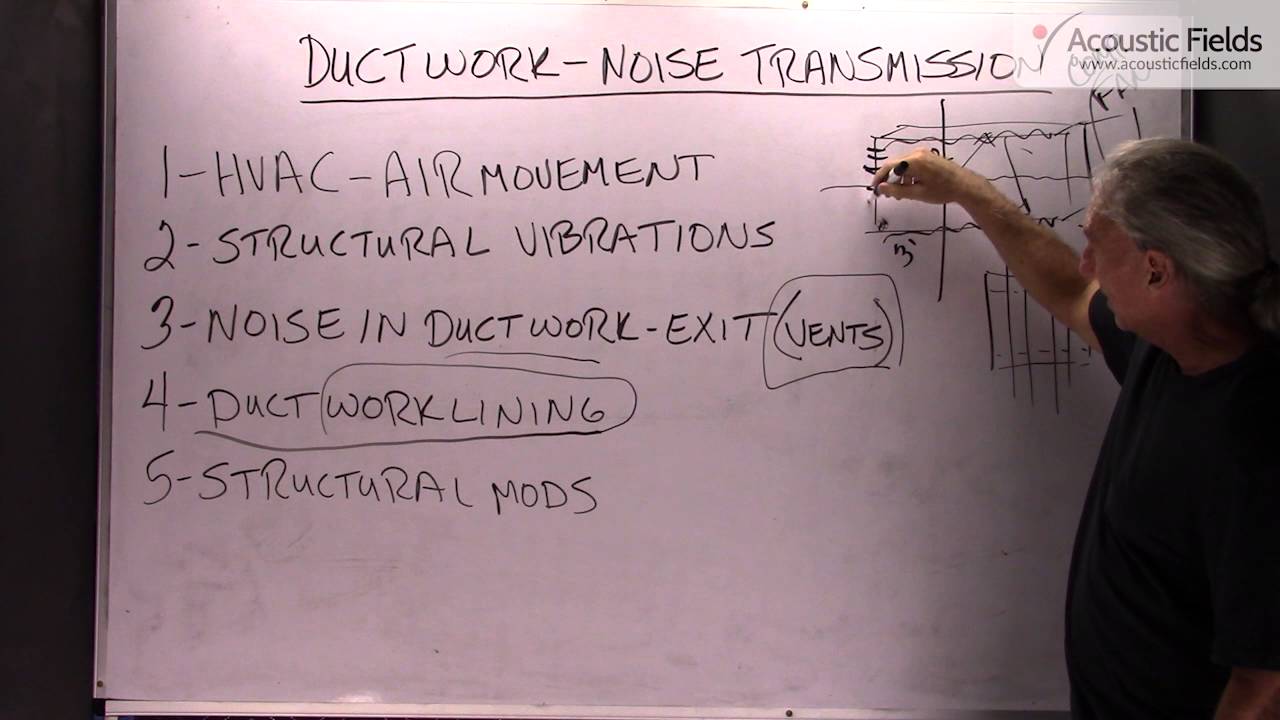

Today I want to talk about ductwork and the noise transmission that goes on in our ductwork, in our HVAC systems, hot air, cool air, depending on what climate and region of the country that you work in. So ductwork sometimes looks like this; square, rectangular tubes and stuff like that goes through our house in there.

So we have the air movement through the ductwork and that air movement, you know, obviously excites the air inside the ductwork. And since it’s a small place we all know about small room acoustics and it’s a constant battle with reflections off these surfaces. So it’s the air inside that gets moving and creates the noise. So depending on the length, depending on the width, depending on the volume of the ductwork you’re going to have certain noise, certain frequencies contributing in that noise at certain amplitude.

So how do we work with the air movement and the structural vibrations? Because usually this ductwork is attached to a compressor that has a fan and all of that gets, you know, all of this moving everything else and then the air inside of the ductwork gets moving. So you have to allow and plan for both of those noise issues. Most of the noise that’s airborne exits through the vent. And about the last 3 feet of every vent is the most noisiest. So you have to allow for that in your planning.

So structurally how do we do that? Well, we work structurally with supports around the ductwork. And you know you can brace the ductwork and minimize the movement of the ductwork and then you can line the inside of the ductwork with different materials. Now you have to be very, very careful here. Lining the ductwork with materials that can break off and be suspended in the air and pushed through the ductwork into the environment, you have to be careful.

Spoke with a gentleman the other day who lined all his ductworks with fiberglass. Well, fiberglass is very harmful. We’ve done a video in our shop and we’ll be releasing it shortly that shows those particles. We put a piece of it on our table and then we dropped a hammer on it and then we filmed all the particles coming up from it. You know, they’re light and they’re suspended in air so you have to be very careful about what kind of material that you put for the lining.

If you’re not concerned with the structural vibration, you’re only concerned with the noise out of the vent here then you want to treat the 3 foot area from the vent into the ductwork and let the rest of the ductwork go. Want some good materials to use? Open celled foams. They don’t shed, they don’t do anything that will hurt you. Building insulation fiberglass, all those particles can come off, get into the air, get into your lungs and then you’ll have all kinds of issues.

If you have a lot of vibration structural modifications we can float the cooler in the fan on isolation feet. We can put isolation technology between the cooler in the fan and the ductwork itself. So there’s all kinds of things that you can do but be very, very careful about what you line in the inside of the ductwork with. And then just use this first 3 foot as your kind of guideline when you’re doing treatment.

—

This is an unedited transcript from our video series from Acoustic Fields. There will be some errors in grammar and sentence structure that occur during this translation process.

For complete understanding and comprehension, please view the video which is included in this text. For any additional information regarding this topic or others relating to room acoustics, please contact us directly at:

P: 520 – 392 – 9486

We use broadband absorption in the two most critical frequency regions in small rooms. Our Diaphragmatic absorbers, ACDA series, have…

Interesting web site and provocative introduction. Please check your copy for typos, otherwise nicely presented. I would like to see…

There is no such thing as soundproof anything especially carpet. Low frequency noise transmission requires a permanent construction fix with…

Hello Dennis! Our neighbors put a Ice Bath in their garage which is right below our bedroom and the Low…